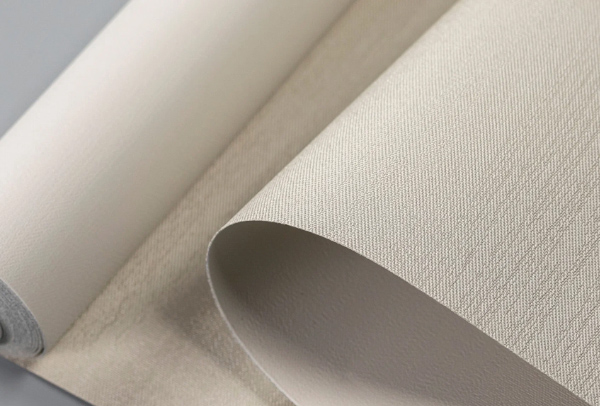

Release paper plays a crucial role in the PVC artificial synthetic leather industry, primarily serving as a mold release agent and surface texture-forming medium during the production process. Below is a detailed analysis of its specific applications and key points:

1. Core Functions of Release Paper

-

Mold Release Function: After the PVC paste is coated and dried, the release paper can be easily peeled off, preventing damage to the synthetic leather surface.

-

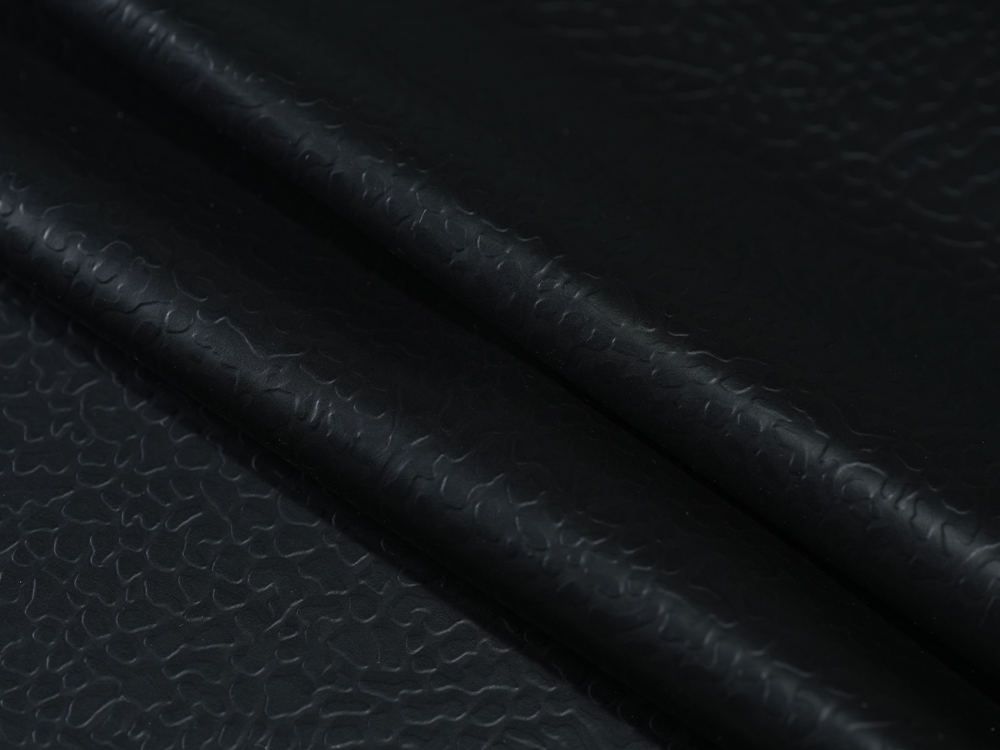

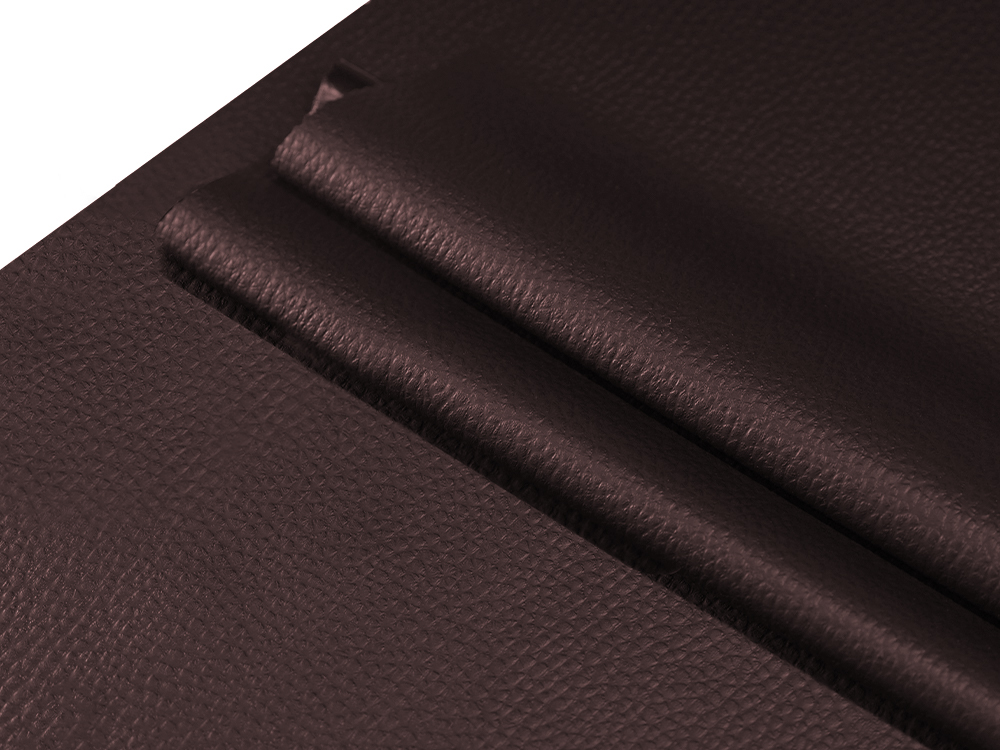

Texture Transfer: The release paper features specific embossed patterns (e.g., lychee grain, PU grain, wood grain) that are precisely replicated onto the PVC surface through embossing, imparting a natural leather-like texture.

2. Process Flow in PVC Synthetic Leather Production

-

Coating: A mixture of PVC resin, plasticizers, stabilizers, and other additives is evenly applied onto the release paper.

-

Drying & Curing: The PVC layer is solidified through oven heating.

-

Peeling: After cooling, the PVC film is separated from the release paper, retaining the paper’s texture.

-

Post-Processing: The peeled PVC layer may be laminated with other substrates (e.g., fabric, non-woven fabric) to form the final product.

3. Key Selection Criteria for Release Paper

-

Heat Resistance: Must withstand high temperatures (typically 150–200°C) during PVC processing to avoid deformation or degradation.

-

Surface Treatment: The amount of silicone coating affects release performance, requiring a balance between easy peeling and texture clarity.

-

Pattern Design: Customized based on market demand (e.g., matte, glossy, 3D embossed patterns).

-

Reusability: High-quality release paper can be reused 3–5 times to reduce costs.

4. Special Requirements for PVC Synthetic Leather

-

Chemical Resistance: Plasticizers (e.g., DOP) in the PVC paste may degrade the paper, necessitating chemical-resistant coatings.

-

Flatness: Ensures uniform coating and prevents bubbles or wrinkles that could affect product quality.

-

Eco-Friendliness: Must comply with regulations such as RoHS and REACH, especially for export products.

5. Differences from PU Synthetic Leather Applications

-

Temperature Requirements: PVC processing temperatures are generally lower than PU, allowing slightly lower heat resistance for release paper.

-

Texture Preference: PVC emphasizes leather-like textures, while PU often pursues microfiber or specialty finishes.

-

Cost Control: PVC synthetic leather is typically mid- to low-end, requiring cost-effective release paper.

6. Industry Trends & Challenges

-

Eco-Friendly Alternatives: Water-based PVC and solvent-free processes demand release paper compatibility with new formulations.

-

High Realism Demand: Development of more complex textures (e.g., crocodile skin, woven effects).

-

Durability Enhancement: Coating technologies extend release paper lifespan, reducing replacement frequency.

Conclusion

Release paper is a critical auxiliary material for achieving surface diversity and production efficiency in PVC artificial synthetic leather. As the industry moves toward premium and eco-friendly development, performance optimization (e.g., heat resistance, chemical resistance, texture innovation) will continue to drive quality upgrades in PVC synthetic leather. Manufacturers must select release paper types based on product positioning (e.g., footwear, furniture, automotive interiors) to balance cost and performance.

English

English 中文简体

中文简体