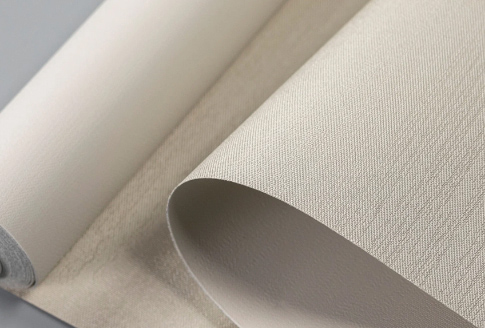

Honghuan high temperature release paper is a kind of anti-adhesive paper specially designed for high-end artificial leather production. It is made of high-quality release paper and special silicone-based coating. It has excellent high temperature resistance and can still maintain flatness, tension and tear strength in an oven environment at 220°C, ensuring high-quality production of PVC leather products. In addition, the release paper has good reusability and can be reused 50 to 60 times in semi-PU production and 8 to 15 times in PVC production, significantly reducing production costs.

Submit feedback

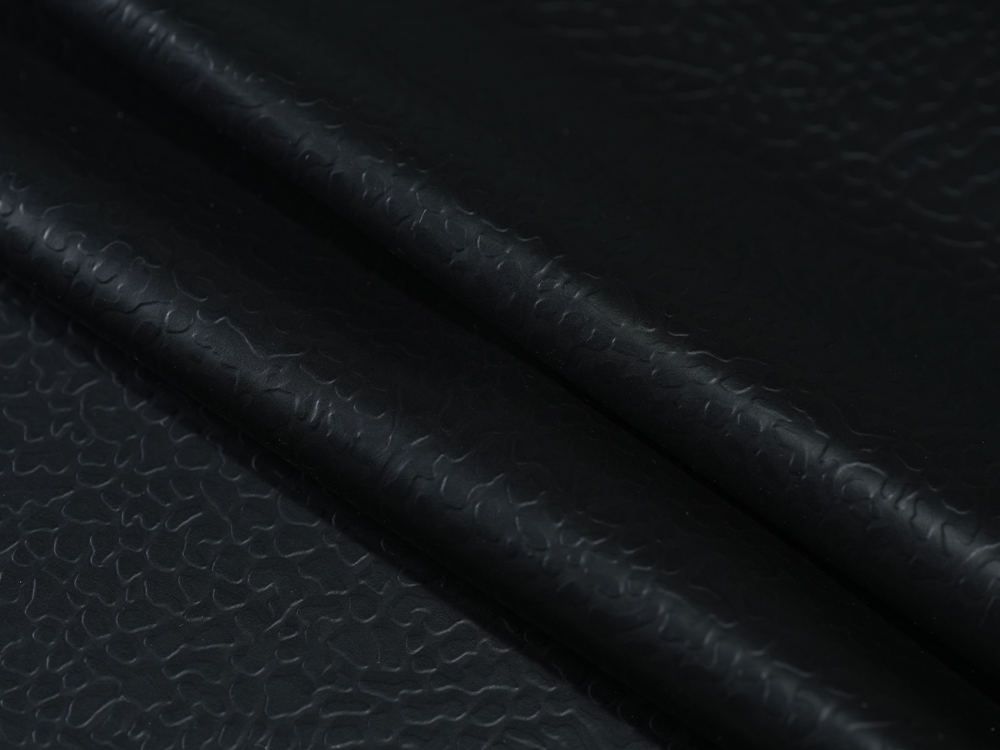

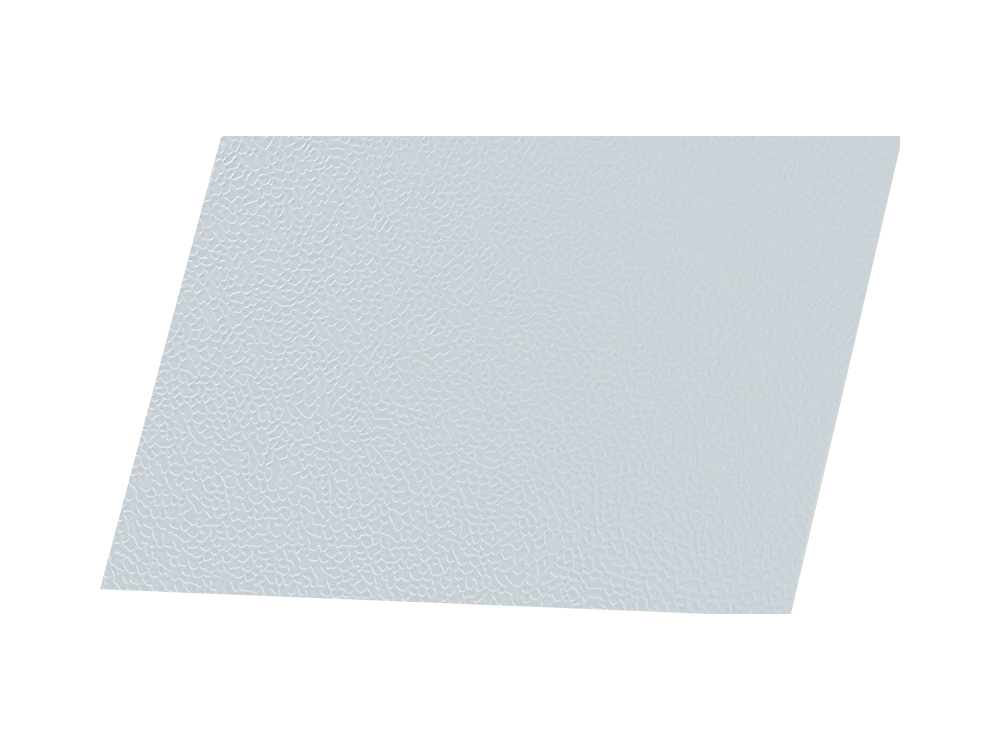

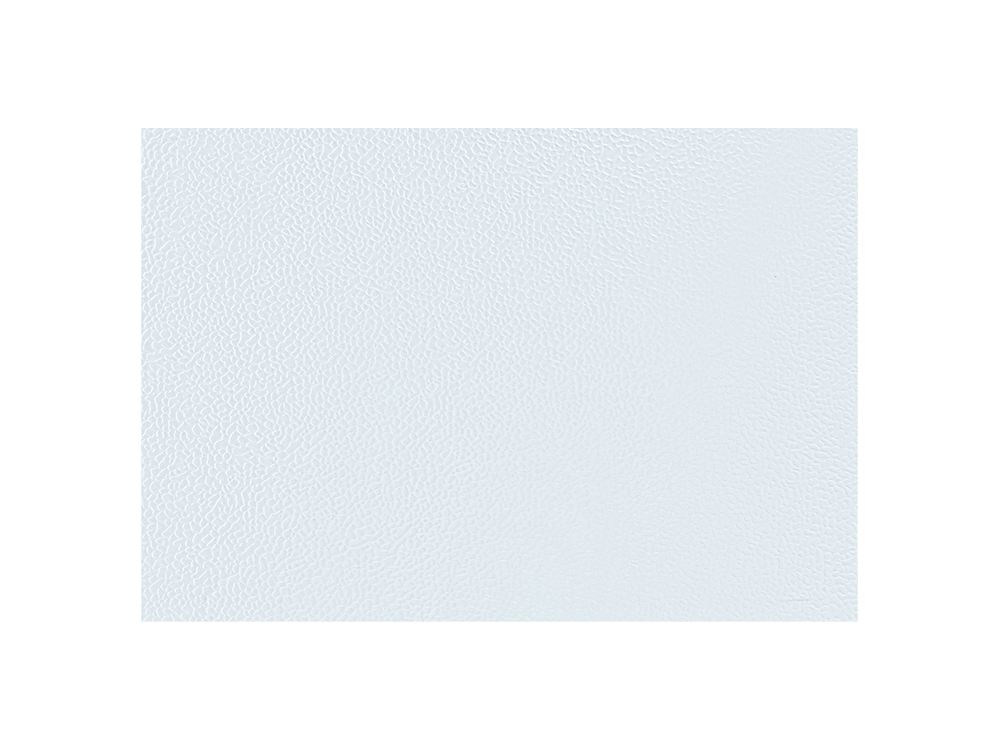

H338 Gemstone Semi-matte High Temperature Release Paper

| Item | Details |

|---|---|

| Paper Specifications | The width is adjustable from 1500 mm to 2350 mm per customer's needs, supporting customized production. |

| High-Temperature Performance | Maintains flatness, tension, folding resistance, and tear strength in high-temperature ovens, ensuring high-quality PVC leather production. |

| Surface Treatment | - Offers plain paper and diverse gloss/texture designs (e.g., various sheens and textures). - Caters to diverse visual effect requirements. |

| Release Force Adjustment | Adjustable to light release or heavy release to suit different PVC leather production needs. |

| Durability & Reusability | - Semi-PU production: Reusable up to 50–60 times. - PVC production: Reusable 8–15 cycles. - Widely praised for durability by users. |

| Gloss Performance (75° Angle) | Gloss level of 30–40, balancing aesthetic appeal and practicality. |

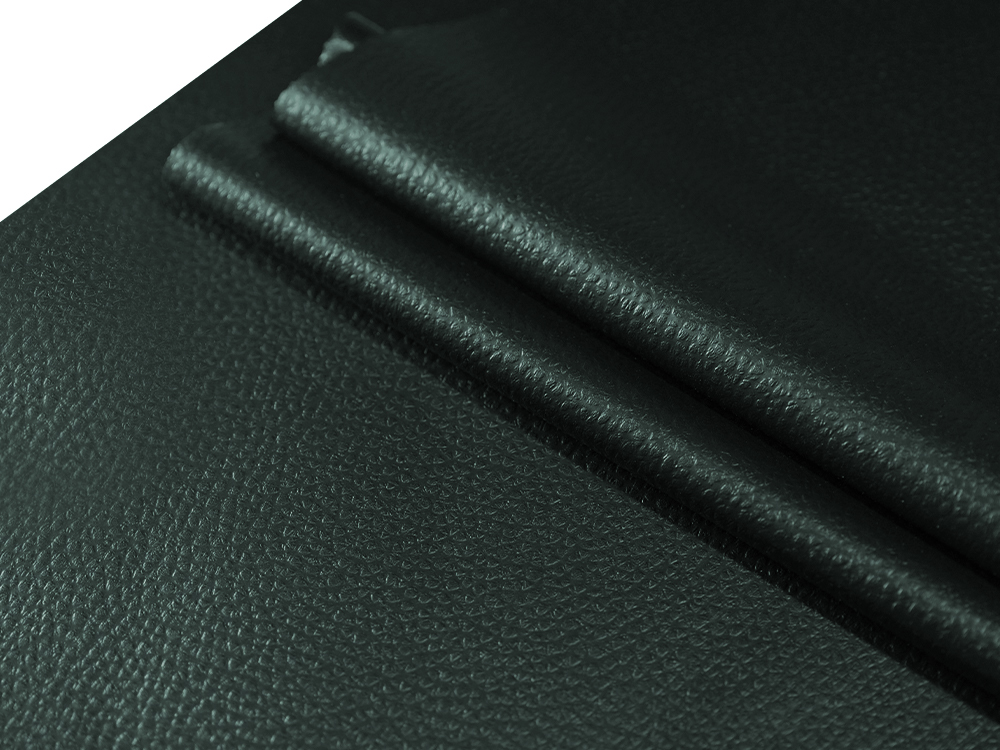

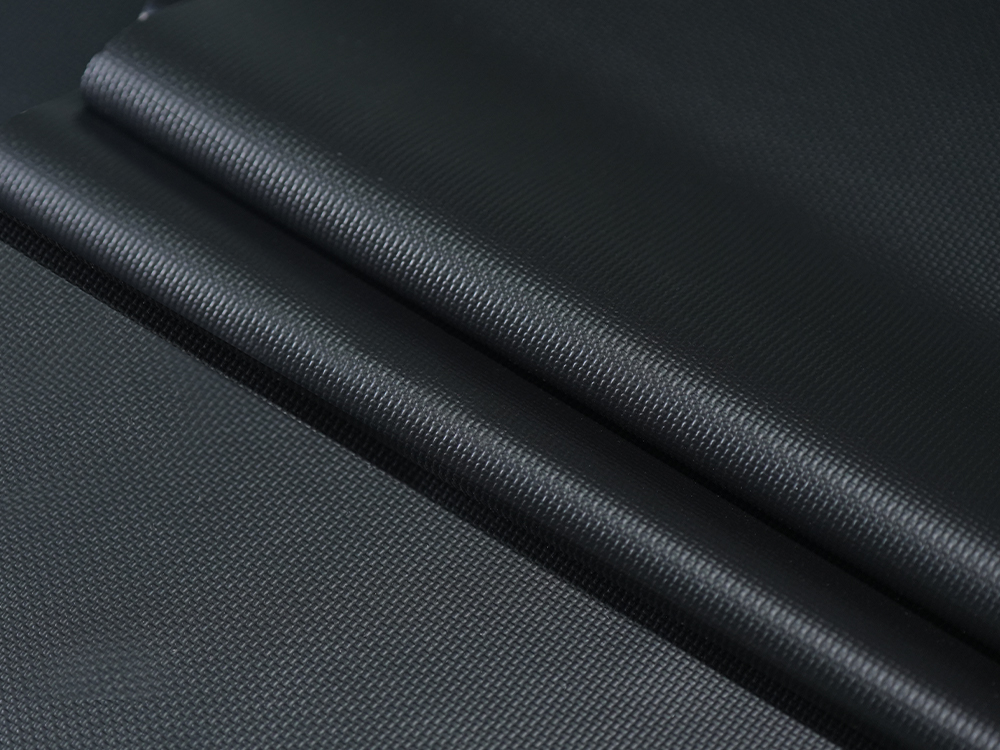

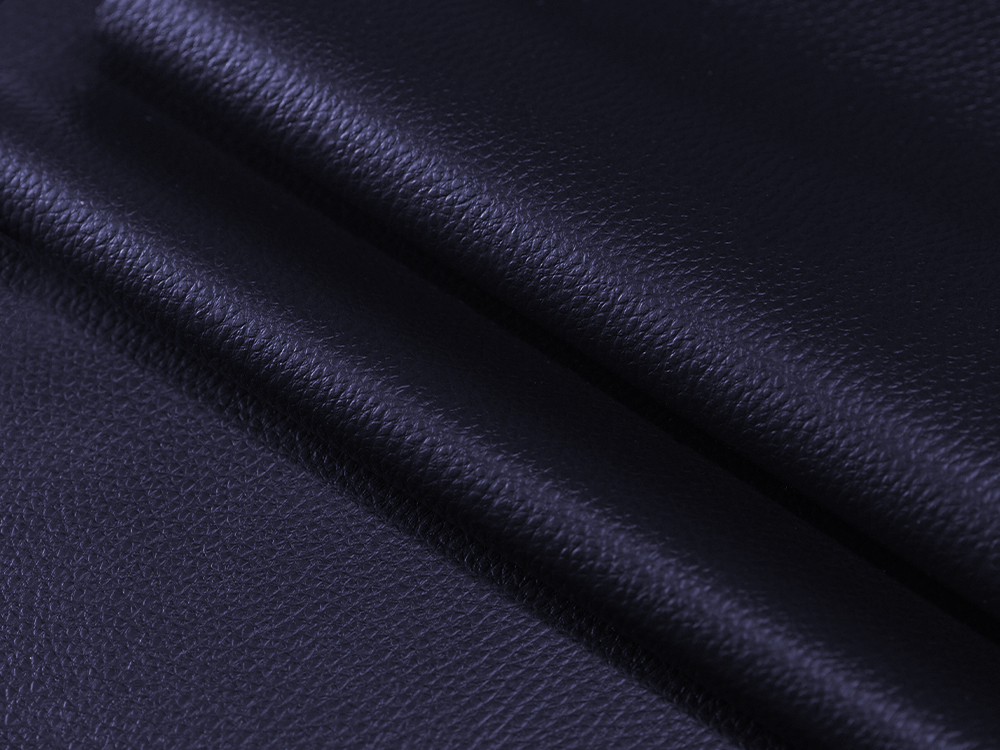

Application fields: Honghuan's high temperature resistant release paper is widely used in the production of high-end artificial leather such as automotive interior leather, floor leather, sofa leather and luggage leather with its excellent performance and beautiful surface design. The unique gemstone pattern design not only enhances the visual effect of the product but also meets the customer's demand for high quality and high cost performance, showing a high degree of flexibility and market competitiveness.

Industry Knowledge Extension

What Makes Gemstone Semi-Matte Release Paper Ideal for High-Temperature Applications?

High Temperature Release Paper is a functional substrate engineered through specialized chemical surface treatments that allow stable demolding under heat-intensive conditions such as hot pressing, calendaring, thermal curing, and texture replication. Its value lies in thermal stability, dimensional constancy, controlled release force, chemical resistance, surface uniformity, and repeat-use durability.

Among its high-end subdivisions, gemstone semi-matte high temperature release paper features a balanced semi-matte surface morphology, offering controlled gloss replication and stable release behavior. It is widely utilized in premium synthetic leather, TPU film, and advanced composite material processing.

A complete technical system for high temperature release paper combines:

- engineered base paper

- precision coating formulation

- surface energy control

- texturing and calendering technology

- thermal curing systems

- quality inspection and long-cycle stability verification

Key Performance Systems and Process Requirements

To ensure stable behavior during heat pressing, lamination, curing, or texture replication, the industry focuses on several core performance pillars:

Thermal Resistance and Dimensional Stability

High-temperature stability—typically between 150–230°C—is essential. Stability depends on:

- fiber orientation and base-paper density

- controlled moisture balance

- thermal expansion compatibility between the paper core and coating system

Controlled and Consistent Release Force

Release force must be predictable and stable, whether light-release, medium-release, or heavy-release. Stability is influenced by:

- uniform silicone coating structure

- curing completeness

- surface flatness and pore structure of the paper

Gemstone semi-matte high temperature release paper excels in producing stable and adjustable release-force platforms, making it suitable for applications requiring precise optical and surface control.

Surface Morphology and Texture Replication

High temperature release paper is also a texture-transfer medium. Its surface geometry defines the final appearance of synthetic leather or functional films.

| Surface Type | Characteristics | Typical Application |

|---|---|---|

| High-gloss | Excellent reflectivity; smooth texture replication | Glossy PU, functional films |

| Semi-matte | Balanced gloss; soft optical effect | Premium synthetic leather |

| Matte | Strong light scattering; premium tactile feel | Sports leather, automotive interiors |

| Patterned | Custom textures; micro-imprinting | Advanced decorative surfaces |

Semi-matte surfaces are particularly popular in high-grade leather and TPU processing, forming a key advantage of gemstone semi-matte high temperature release paper.

Coating Uniformity and Structural Durability

Coating uniformity affects:

- release-force stability

- clarity of texture replication

- number of repeat use cycles

Leading manufacturers employ high-precision coating and segmented thermal-curing to ensure long-term structural reliability.

Manufacturing Systems and Quality Control

Production of high temperature release paper involves pulping, calendering, multi-layer coating, curing, embossing, and precision slitting. Even slight variations may influence release behavior or pattern fidelity. The industry therefore relies on strict automation and inspection systems.

Anhui Honghuan New Material Technology Co., Ltd., a professional integrated enterprise specializing in R&D, production, and sales, represents the typical structure of modern manufacturing systems:

DETECTION

Advanced testing equipment, including pilot coating machines and analytical instruments, ensures consistent quality through precise measurement of coating thickness, curing performance, surface energy, and thermal stability.

EFFICIENCY

Strict cycle-time control governs the entire production process. For urgent orders, flexible scheduling ensures rapid delivery without compromising process stability.

PRODUCTION CAPABILITY

Automated and semi-automated lines enhance uniformity and productivity, supporting high annual output and reliable supply.

MANUFACTURING BASE

Two self-operated factories allow the company to maintain competitive pricing, stable quality control, and consistent production capability.

Stable Production System

With a fully developed supply chain for base paper and chemical raw materials, Anhui Honghuan ensures uninterrupted production regardless of external economic conditions.

Application Fields and Functional Roles

High temperature release paper is indispensable in various processing environments, serving as both a protective processing carrier and a surface-texture replication medium.

Synthetic Leather Industry (Primary Application)

As a manufacturer of high-temperature release paper for synthetic leather, Honghuan supplies materials essential for PU, PVC, and TPU calendaring, coating, and embossing processes. Semi-matte grades such as gemstone semi-matte high temperature release paper are especially suited for premium footwear leather, fashion leather, and automotive interior materials.

Adhesives and Electronic Materials

Used for hot-melt adhesives, pressure-sensitive adhesives, optical bonding materials, and thermal curing systems—requiring:

- consistent release force

- thermal resistance

- ultra-clean surface characteristics

Functional Film Processing

PET, PP, and PE films rely on high temperature release paper for calendering, surface uniformity, and optical-grade smoothing.

Decorative Heat-Press Materials

Wood-grain films, furniture laminates, and abrasion-resistant layers depend on stable release performance during thermal lamination.

Conclusion

The competitiveness of high temperature release paper lies in the integration of material science, coating technology, calendering precision, texture control, and rigorous quality management. Products such as gemstone semi-matte high temperature release paper are closely aligned with emerging demands in synthetic leather, functional films, adhesives, and decorative materials.

Copyright © Anhui Honghuan New Material Technology Co., Ltd. Rights Reserved.

Wholesale H338 Gemstone Semi-matte High Temperature Release Paper Suppliers

English

English 中文简体

中文简体