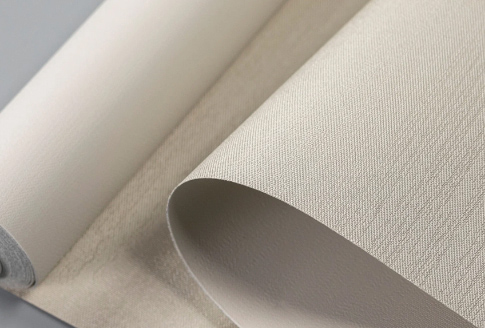

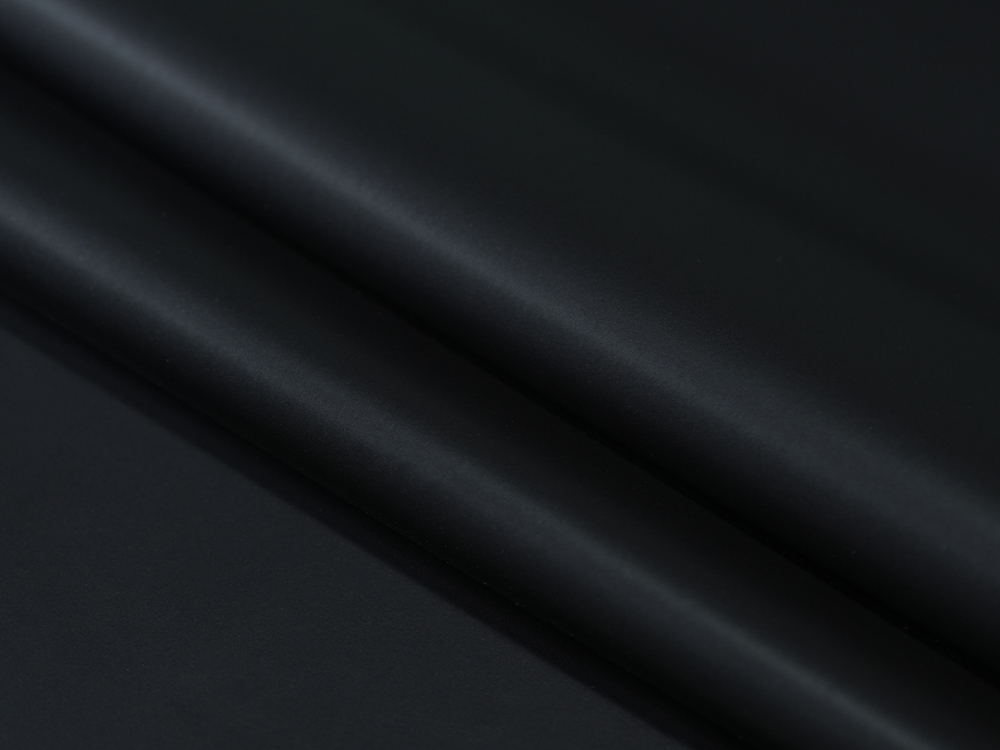

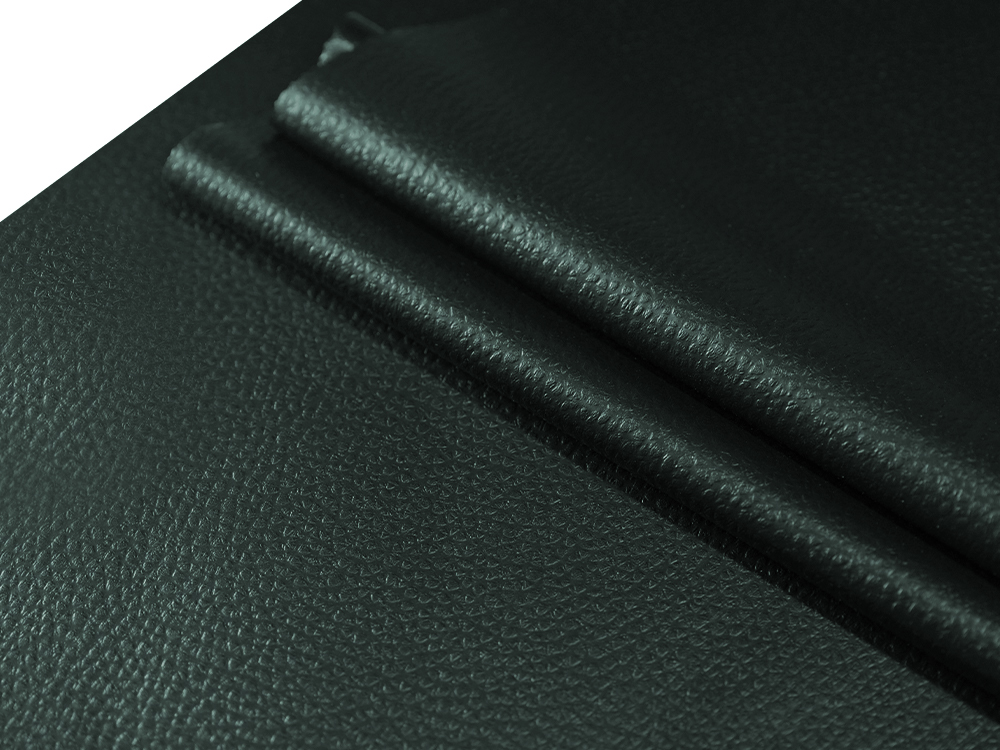

Honghuan high temperature release paper is a kind of anti-adhesive paper specially designed for synthetic leather production. It is made of high-quality release paper and special silicon-based coating, with good flatness and durability. The leather surface produced can present a small litchi grain semi-bright effect with moderate glossiness, which is both beautiful and practical. This product can be reused and is suitable for the production of semi-PU and PVC leather to meet diverse visual needs.

Submit feedback

H658 Small Litchi Pattern Semi-Bright High Temperature Release Paper

| Item | Details |

|---|---|

| Paper Specifications | Customizable width from 1500 mm to 2350 mm to meet diverse customer production needs. |

| High-Temperature Stability | Maintains stable flatness, tension, folding resistance, and tear strength in a 220°C oven, ensuring high-quality PVC leather production. |

| Surface Treatment | - Uniform small lychee texture effect. - Moderate gloss level to meet visual appeal requirements. |

| Release Force Adjustment | Adjustable to light release or heavy release for different PVC leather production needs. |

| Durability & Reusability | - Semi-PU production: Reusable up to 50–60 times. - PVC production: Reusable 8–15 cycles. - Widely praised for excellent reusability. |

| Gloss Performance (75° Angle) | Glossiness of 40–50, balancing aesthetic beauty and practical functionality. |

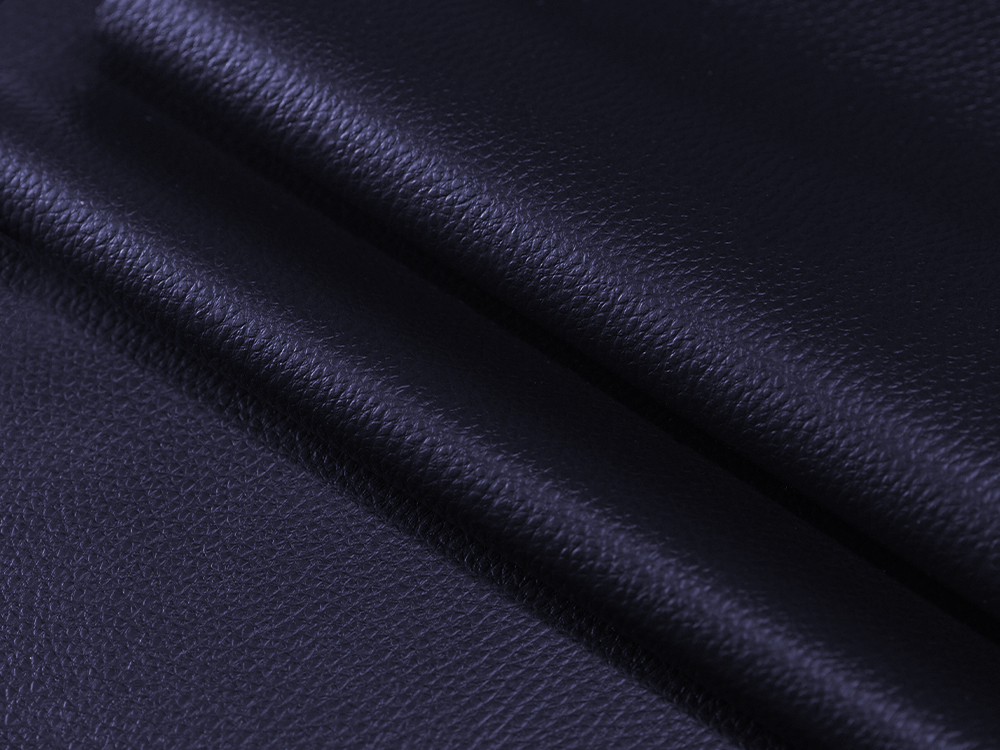

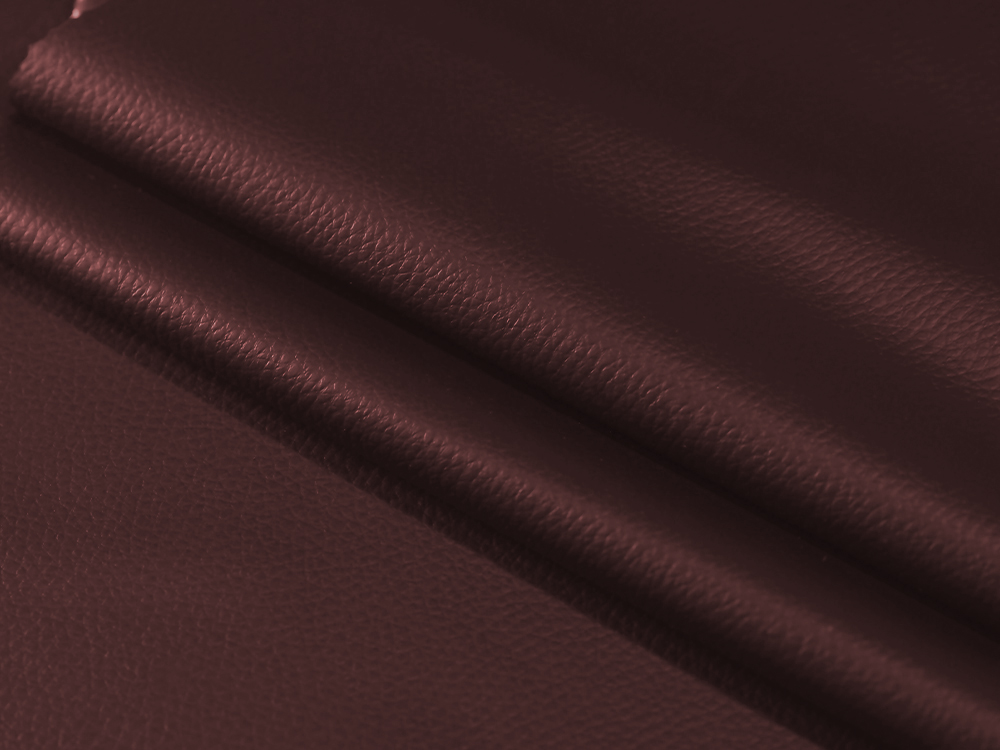

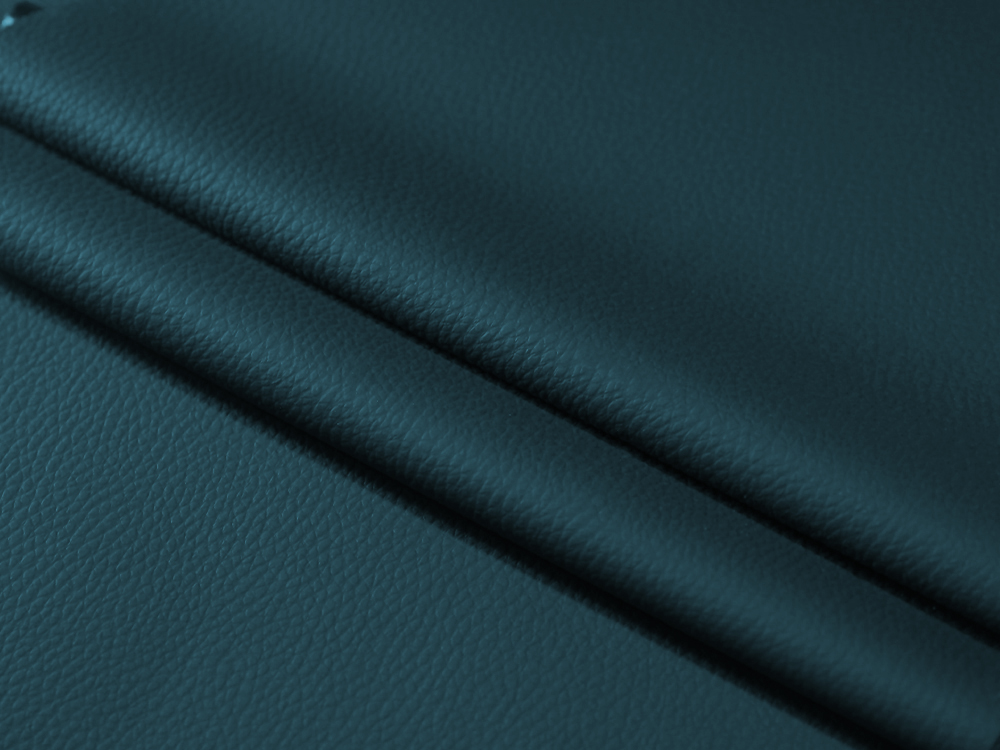

Application fields: Honghuan's high temperature resistant release paper is widely used in many fields such as automotive interior leather, floor leather, sofa leather and luggage leather due to its excellent performance. Its small litchi grain semi-bright effect gives leather products a unique texture and visual appeal, while meeting the strength and stability requirements during high temperature processing, showing a high degree of flexibility and practicality.

Industry Knowledge Extension

Industry Insights on High Temperature Release Paper

High temperature release paper plays a crucial role in multiple industrial processes, especially in fields where stability, clean release, and precision surface replication are required. As a trusted manufacturer of H658 Small Litchi Pattern Semi-Bright High Temperature Release Paper, Anhui Honghuan New Material Technology Co., Ltd. provides solutions that support consistent performance in demanding production environments.

About High Temperature Release Paper Applications

High temperature release papers are widely applied in synthetic leather manufacturing, composite materials processing, hot-press molding, adhesive products, lamination, and other industrial operations. Their stability and ability to withstand elevated temperatures make them essential for maintaining product quality and production efficiency.

Key Industrial Advantages

- Stable performance under high temperatures

- Accurate surface texture replication

- Improved release efficiency and reduced residue

- Extended service life for repeated use

- Consistency in mass production processes

Features of H658 Small Litchi Pattern Semi-Bright High Temperature Release Paper

The H658 Semi-Bright Litchi Pattern release paper delivers reliable surface consistency and excellent temperature resistance. It is commonly used in artificial leather, PU, PVC lamination, and thermoforming applications.

| Feature | Description |

|---|---|

| Surface Pattern | Small litchi texture with semi-bright finish |

| Temperature Resistance | Suitable for high-temperature molding and lamination |

| Release Performance | Clean and consistent release with minimal residue |

| Application | PU synthetic leather, PVC films, high-pressure molding |

| Reusability | High durability for repeated production cycles |

Why Industries Choose High Temperature Release Paper

Manufacturers in the synthetic leather, footwear, automotive interior, and packaging industries often require materials that maintain reliable performance across hundreds of cycles. High temperature release papers provide essential stability and precise texture for premium surface finishes, especially in PU and PVC production.

Performance Comparison Chart

| Type | Temperature Resistance | Surface Stability | Recommended Use |

|---|---|---|---|

| Semi-Bright Litchi Pattern (H658) | High | Excellent | PU Leather, PVC, Hot Press Molding |

| Matte Release Paper | Medium | Good | General Lamination |

| Super Gloss Release Paper | High | High Gloss Applications | Luxury Packaging, Decorative Films |

About Anhui Honghuan New Material Technology Co., Ltd.

Located in Shitan Industrial Park, Quanjiao County, Chuzhou City, Anhui Province, Anhui Honghuan New Material Technology Co., Ltd. was established by Kunshan FASTER New Materials Group with a total investment of RMB 300 million. Covering 58 acres and benefiting from convenient highway, railway, and airport access, the company ensures efficient logistics and strong production capacity.

As a modern enterprise integrating R&D, manufacturing, and sales, Honghuan focuses on innovative release paper, PE-coated paper, and specialty packaging materials. Since the successful development of high-temperature release paper in 2019, the company has continued to expand its technological capabilities to support industrial customers worldwide.

FAQs About High Temperature Release Paper

1. What temperatures can high temperature release paper withstand?

Depending on the specific formulation, high temperature release papers can withstand elevated temperatures used in PU, PVC, and thermoforming applications, ensuring stable performance without deformation.

2. What makes the litchi pattern popular?

The small litchi surface provides a natural, uniform texture commonly preferred in synthetic leather products such as bags, furniture, and automotive interior materials.

3. Can the H658 release paper be reused?

Yes, the H658 model is designed for repeated production cycles due to its strong durability and stable surface coating.

4. What industries benefit the most from this type of release paper?

Industries producing PU leather, PVC films, footwear materials, furniture upholstery, automotive interior components, and laminated packaging benefit greatly from high temperature release paper.

5. Does surface uniformity affect product quality?

Absolutely. The consistency of the release paper's texture has a direct impact on the final product appearance, making high-quality release paper essential for premium-grade materials.

Copyright © Anhui Honghuan New Material Technology Co., Ltd. Rights Reserved.

Wholesale H658 Small Litchi Pattern Semi-Bright High Temperature Release Paper Suppliers

English

English 中文简体

中文简体