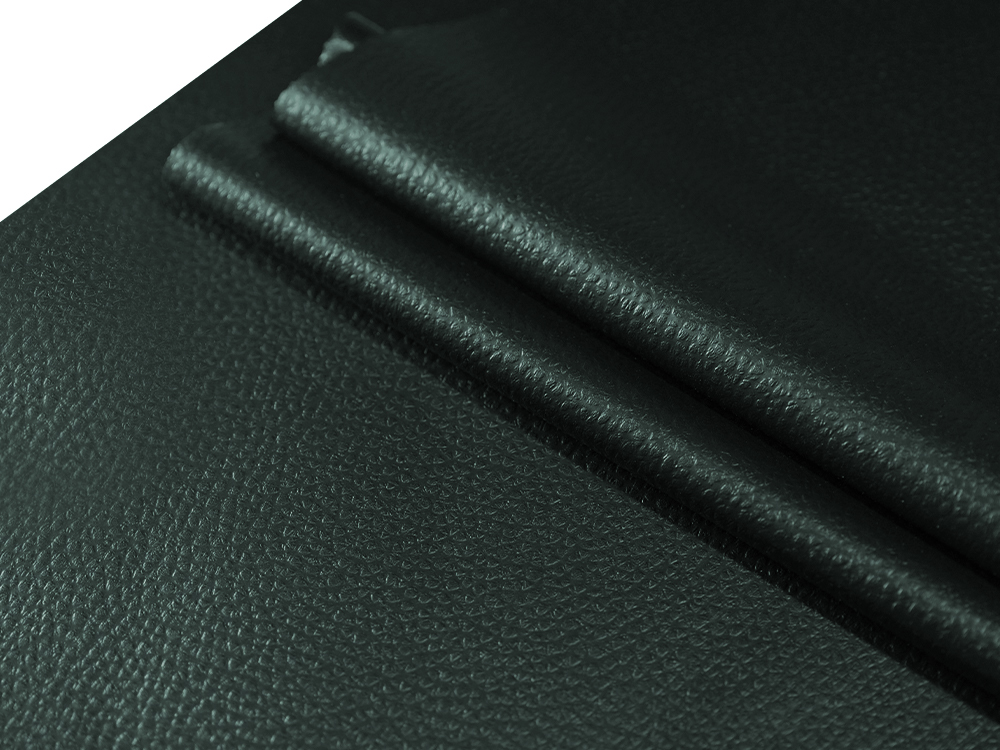

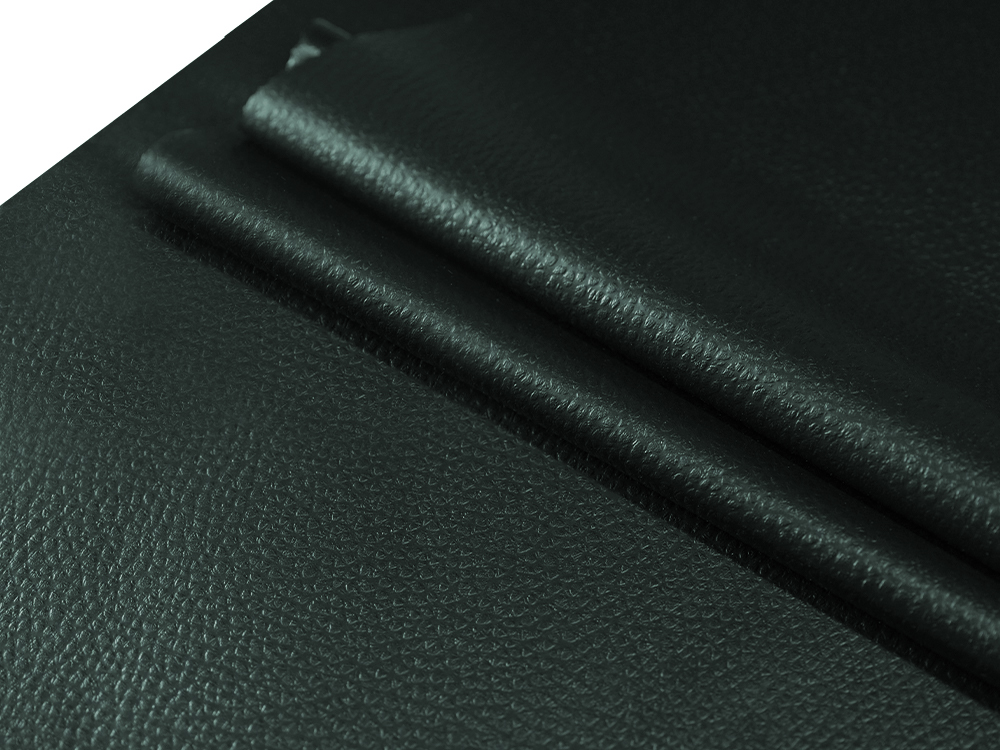

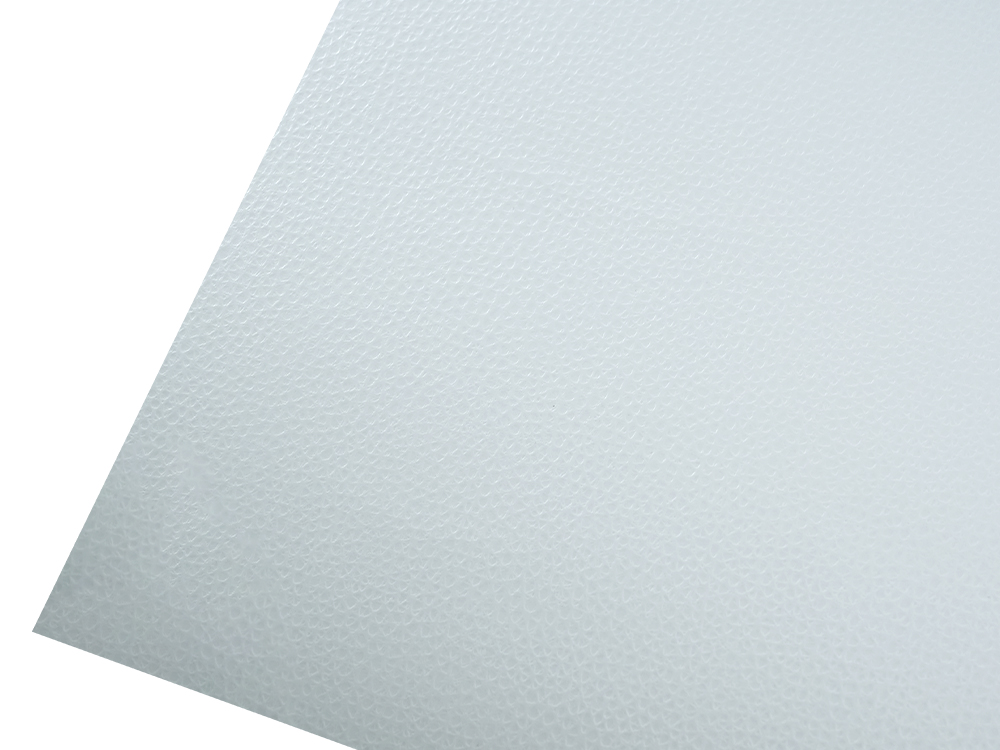

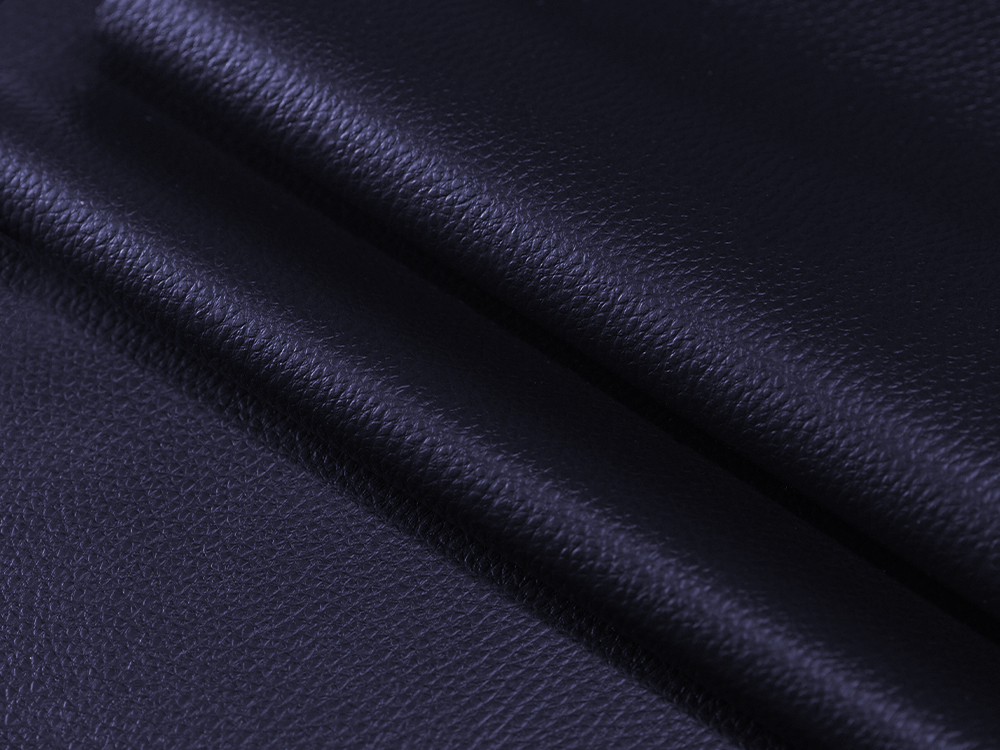

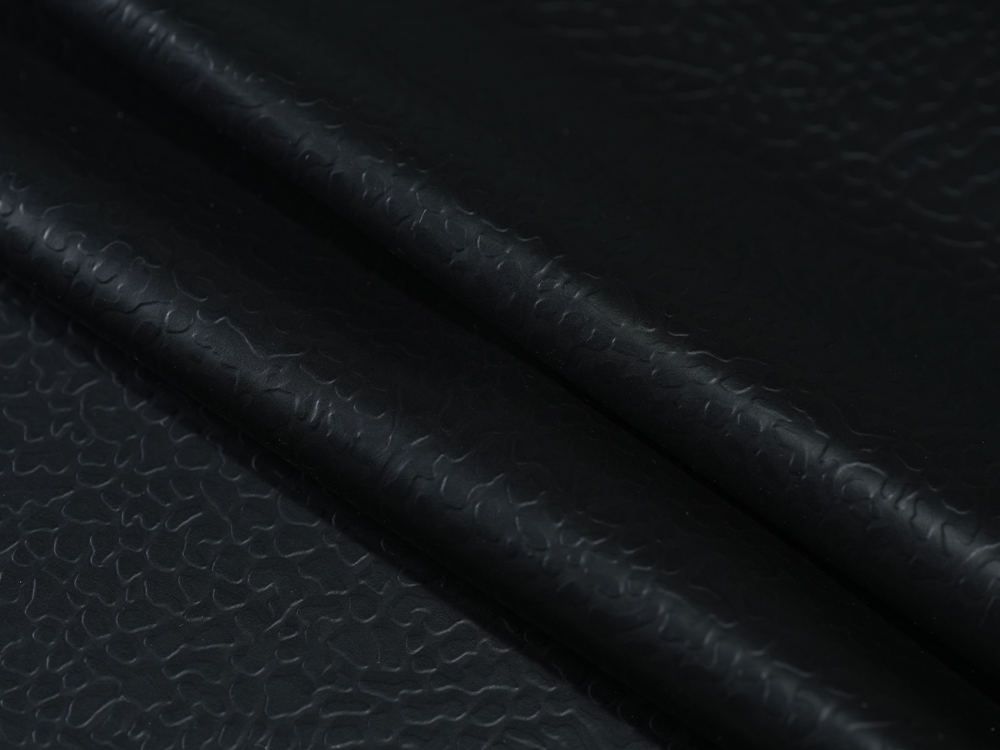

Honghuan high-temperature release paper is a high-quality release paper designed for synthetic leather production. It is made of a special silicon-based coating combined with a high-toughness, strong base paper, and has excellent high-temperature resistance and anti-stick properties. The leather surface produced by it can form a unique litchi effect with moderate glossiness, which is suitable for the production of semi-matte PVC and semi-PU leather. This product not only has good flatness and durability, but also can maintain a stable release force in a high-temperature environment, ensuring high efficiency and product quality during the production process.

Submit feedback

H538 Large Lychee Pattern Semi-matte High Temperature Release Paper

| Item | Details |

|---|---|

| Specifications & Customization | - Width range: 1500 mm to 2350 mm, adjustable per customer needs. - Fits customization requirements for different production lines. |

| High-Temperature Resistance | - Maintains flatness, tension, folding resistance, and tear strength at 220°C in ovens. - Ensures high-quality PVC leather production. |

| Surface Treatment | - Offers diverse glossiness options (semi-matte finish). - Customizable special patterns (e.g., large lychee grain) for visual diversity. |

| Release Force Adjustment | - Adjustable to light release or heavy release. - Meets process requirements for different PVC leather types. |

| Durability & Reusability | - Semi-PU/PVC production: Reusable up to 50–60 times. - Significantly reduces production costs through excellent reusability. |

| Glossiness & Texture | - Glossiness (75° angle): 30–40 (semi-matte). - Natural and aesthetic lychee grain texture, suitable for high-end leather products. |

Application fields: Honghuan's high-temperature resistant release paper is widely used in the production of high-end synthetic leathers such as automotive interior leather, floor leather, sofa leather, and luggage leather due to its excellent performance. Its unique lychee effect and moderate glossiness make it an ideal choice for fashionable home furnishings and automotive interiors, while meeting the dual needs of environmental protection and efficient production.

Industry Knowledge Extension

High Temperature Release Paper: What Factors Determine Its Performance Advantages and Industrial Value?

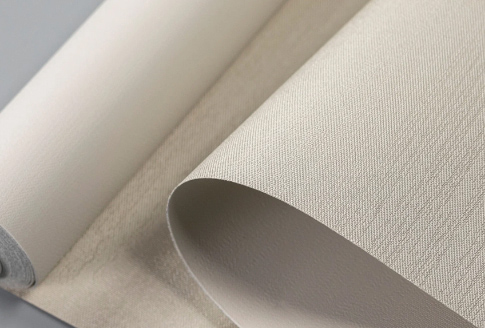

High temperature release paper is a type of functional paper material designed to maintain excellent release performance under high-temperature conditions. Its applications have expanded across electronics, electrical, composite materials, and high-temperature laminating industries. Recently, with the development of semi-matte high temperature release paper and other high-performance products, this material not only ensures process efficiency but also plays a significant role in precision manufacturing and environmentally friendly material replacement.

Definition and Classification of High-Temperature Release Paper

High-temperature release paper refers to paper treated with a special coating to remain stable in releasing adhesive substances under high temperatures. Its primary function is to prevent sticking or damage during hot pressing, thermal lamination, or high-temperature composite processes, ensuring smooth surfaces without residue.

Based on surface treatment and application, high-temperature release paper can be classified as follows:

| Type | Characteristics | Main Applications |

|---|---|---|

| Silicone-coated high-temperature release paper | Evenly coated with high-temperature silicone oil; high heat resistance and stable release | Electronics, thermal transfer films |

| Semi-matte high temperature release paper | Semi-matte surface texture balancing aesthetics and high-temperature release performance | Home decoration, composite material lamination |

| PE-coated high-temperature release paper | Coated with polyethylene to enhance moisture and heat resistance | Packaging materials, composite board processing |

Semi-matte high-temperature release paper is preferred in high-end decorative materials, electronic insulation films, and composite lamination due to its stable performance and visually appealing surface.

Material Composition of High-Temperature Release Paper

The performance of high-temperature release paper depends on both the substrate and surface coating. Substrates are typically high-strength pulp paper or specialty fiber paper to prevent warping or tearing under high heat. Surface coatings determine release performance and heat resistance and usually include silicone oil, PE coatings, or other functional resins.

| Material | Function | Key Features |

|---|---|---|

| Pulp/fiber-reinforced paper | Provides substrate strength and flexibility | High heat resistance, tear-resistant |

| Silicone oil coating | Provides low adhesion surface | Heat-resistant, smooth release |

| PE coating | Enhances moisture resistance and isolation | Waterproof, chemically resistant |

| Functional resins | Imparts specialized surface properties | Adjustable gloss, wear resistance |

Anhui Honghuan New Material Technology Co., Ltd. specializes in the innovative manufacturing of semi-matte high-temperature release paper and other specialty packaging materials. By optimizing the combination of substrate and coating materials, they achieve stable performance even in processes above 200°C.

Key Performance Indicators

In industrial applications, high temperature release paper must meet the following core performance requirements:

- High-Temperature Resistance

The product should maintain shape and prevent carbonization while preserving release performance under high heat. - Release Force Stability

The release force must be uniform during hot pressing or lamination to avoid adhesive residue. - Surface Gloss and Texture

Semi-matte high-temperature release paper provides a balance between aesthetic appearance and functional release. - Dimensional Stability

Paper must maintain size and thickness under temperature and humidity changes to ensure processing accuracy. - Environmental Compliance

Silicone oil and coating materials must meet international environmental standards, reducing VOC emissions.

Processing and Customization Services

Anhui Honghuan New Material Technology Co., Ltd. provides end-to-end customization from material selection to coating formula optimization. Key services include:

- Customized Development: Tailored semi-matte high-temperature release paper according to gloss levels and EMB design requirements.

- OEM/ODM Support: Branding and label customization according to client needs.

- Flexible Size Options: Widths ranging from 1,600mm to 2,350mm, adjustable per order.

- Low Minimum Order Quantity: MOQ as low as 2,000 meters per roll, suitable for small-scale clients.

- Comprehensive Logistics Support: Experienced transportation ensures safe and timely delivery.

These services enable customers to obtain high-performance, customized solutions efficiently.

Advantages and Applications of Semi-Matte High Temperature Release Paper

Semi-matte high-temperature release paper is gradually replacing traditional glossy or fully matte release paper, offering several advantages:

- Balanced Visual and Tactile Properties

Semi-matte surface avoids glare while providing a smooth, premium feel. - Stable High-Temperature Release Performance

Suitable for processes exceeding 200°C with uniform release and no residue. - Eco-Friendly and Sustainable

Environmentally friendly silicone oil and degradable coatings meet green manufacturing requirements. - Processing Flexibility

Widely applicable in composite boards, electronic insulation films, high-end packaging, and furniture decoration.

| Advantages | Industrial Value |

|---|---|

| Semi-matte surface | Enhances product appearance and premium perception |

| High-temperature stability | Ensures smooth hot-press and lamination processes |

| Eco-friendly materials | Meets international green manufacturing standards |

| Customizable specifications | Adapts to diverse industrial processing needs |

Conclusion

High-temperature release paper, particularly semi-matte high temperature release paper, plays an indispensable role in modern industry. By optimizing material formulations, improving coating techniques, and providing customized services, Anhui Honghuan New Material Technology Co., Ltd. is able to offer high-performance, environmentally friendly, and aesthetically pleasing products.

Copyright © Anhui Honghuan New Material Technology Co., Ltd. Rights Reserved.

Wholesale H538 Large Lychee Pattern Semi-matte High Temperature Release Paper Suppliers

English

English 中文简体

中文简体