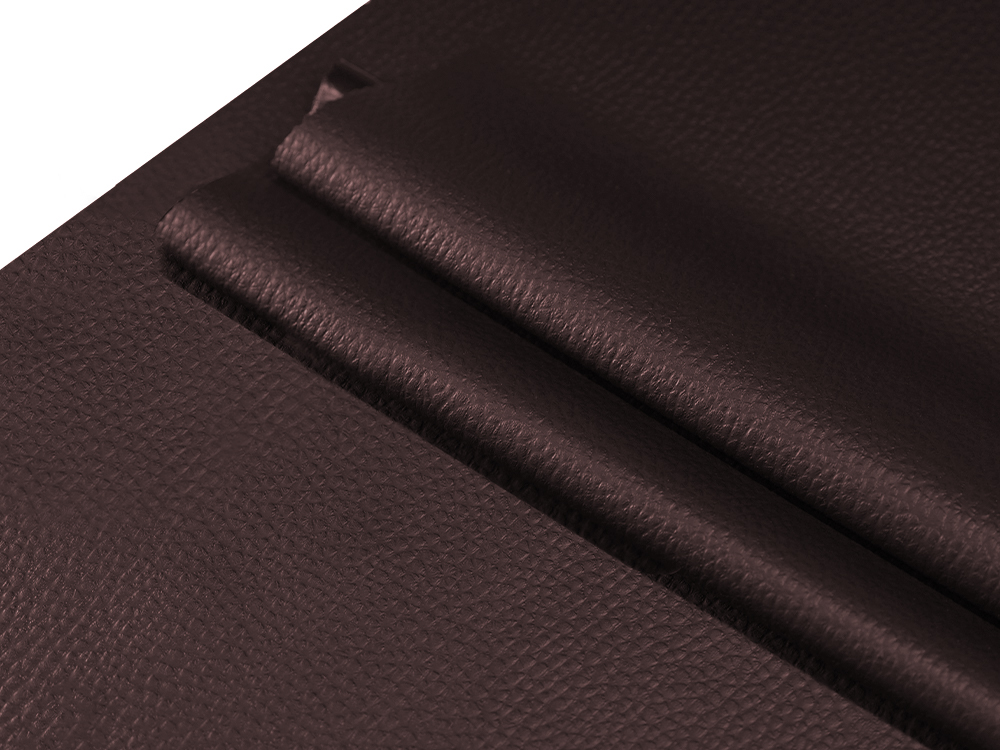

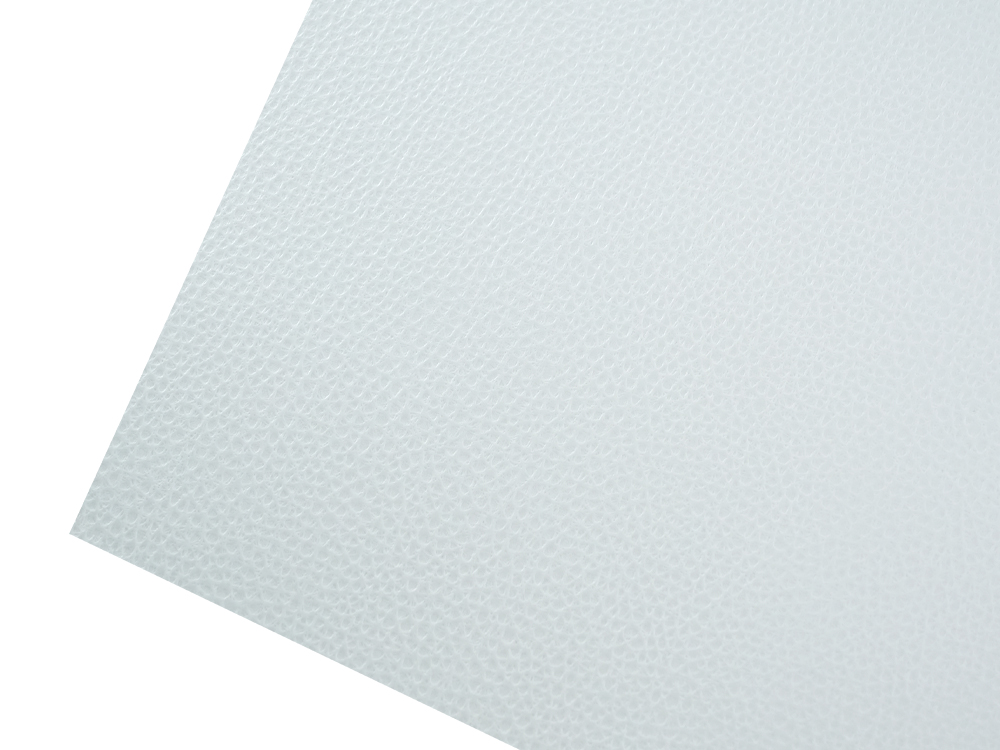

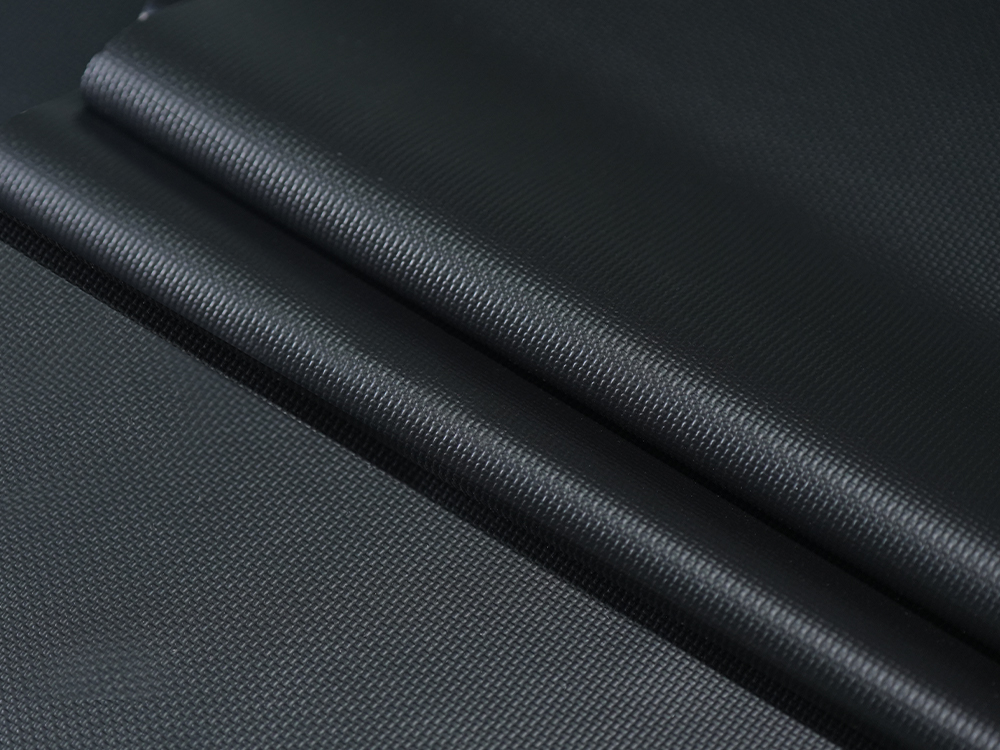

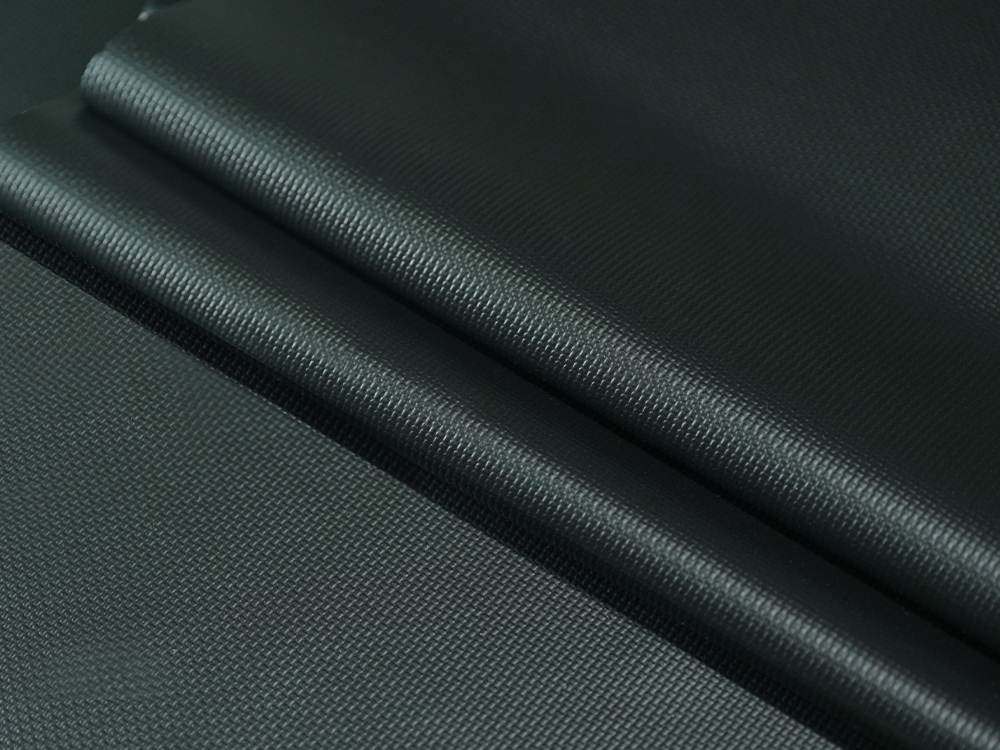

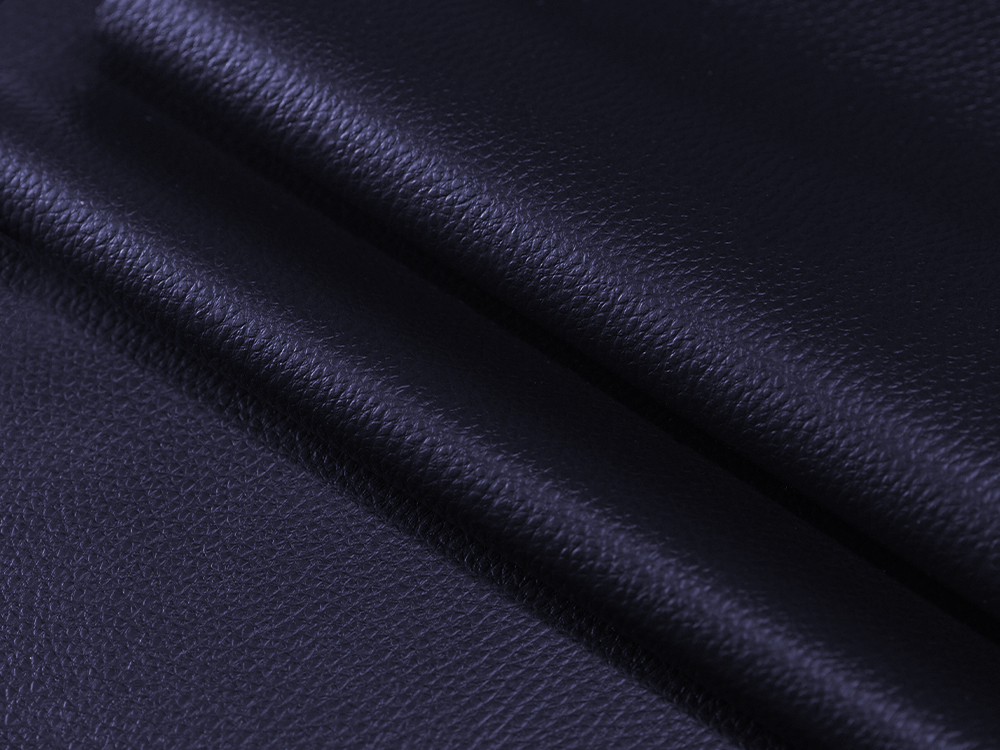

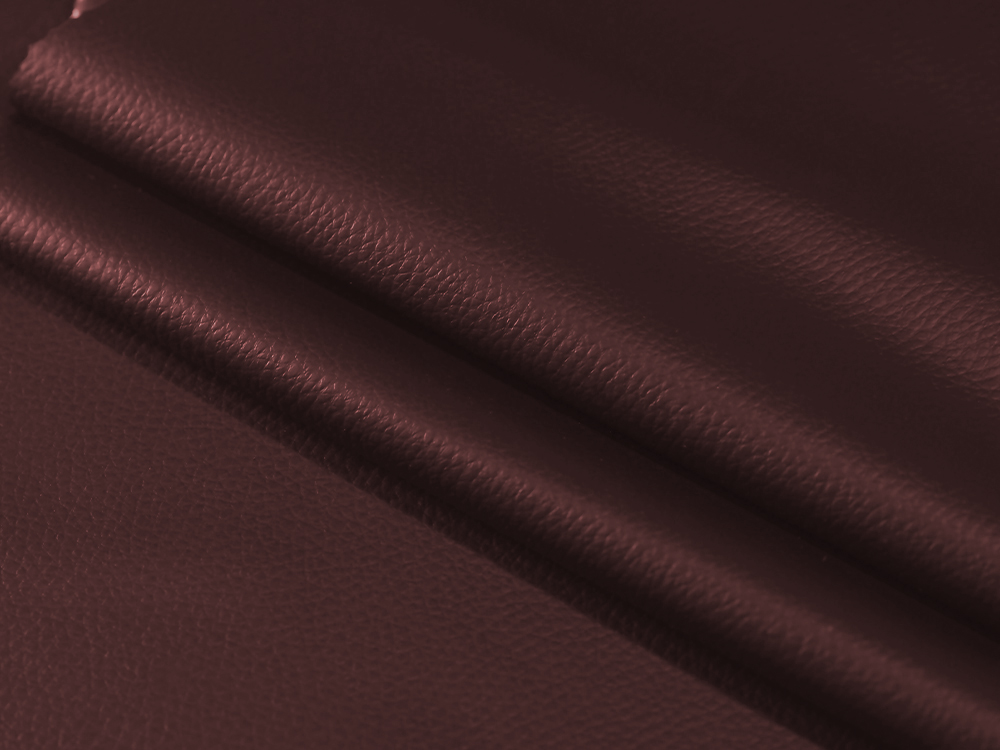

Honghuan high-temperature release paper is a high-performance anti-adhesive paper designed to meet the high requirements of synthetic leather production. The leather surface produced with this release paper can present large lychee grain, and the matte effect is natural and soft, which is both beautiful and practical, and is suitable for a variety of high-end artificial leather products. Made of high-quality release paper and special silicone-based coating, this paper has excellent heat resistance and durability, and can maintain stable performance in high-temperature environments.

Submit feedback

H518 Large Litchi Texture Matte High Temperature Release Paper

| Item | Details |

|---|---|

| Paper Specifications | Width is customizable from 1500 mm to 2350 mm to meet diverse customer customization needs. |

| High-Temperature Stability | Maintains flatness, tension, folding resistance, and tear strength in a 220℃ oven, ensuring high-quality PVC leather production. |

| Surface Treatment | - Matte finish with natural effect. - Developed a large lychee pattern design to meet high visual requirements. |

| Release Force Adjustment | Adjustable to light or heavy release force to suit different PVC leather production processes. |

| Durability & Reusability | - Semi-PU production: Reusable 50–60 times. - PVC production: Reusable 8–15 cycles. - Highly praised for durability by users. |

| Gloss Performance (75° Matte Angle) | Glossiness of 10–20, delivering a natural matte effect suitable for high-end interior applications. |

Application areas: Honghuan's high temperature resistant release paper is widely used in automotive interior leather, floor leather, sofa leather, and luggage leather due to its excellent performance. Its matte effect and litchi pattern design enhance the visual beauty of the product while meeting the strict requirements of the high-end market. The product is also suitable for other synthetic leather production scenarios that require high heat resistance and high durability, showing a high degree of flexibility and practicality.

Industry Knowledge Extension

How Can Release Paper Ensure Quality in High Temperature Processes?

In modern manufacturing and packaging industries, high temperature release paper has increasingly become a critical material in synthetic leather, composite materials, and high-end packaging applications.

Material Properties and Classification

High-temperature release paper is a functional paper designed for high-temperature processing. Its main purpose is to prevent adhesion, ensure smooth demolding, and maintain surface quality and processing efficiency. Based on surface treatment and application, high-temperature release paper can be classified into various types. Among them, matte high temperature release paper is widely used in synthetic leather and hot-pressing processes due to its low gloss, high temperature resistance, and excellent release performance.

Key performance characteristics include:

- Heat resistance: Maintains stable properties under continuous exposure to 180–250°C or higher;

- Release performance: Prevents adhesion to substrates or coatings during processing, reducing scrap rates;

- Dimensional stability: Low deformation under heat, ensuring product precision;

- Environmental friendliness: Often produced using solvent-free coating processes, meeting modern green manufacturing requirements.

| Performance | Technical Requirement | Application |

|---|---|---|

| Heat resistance | ≥230°C continuous use | Synthetic leather hot pressing, thermal transfer, composite material forming |

| Release force | Moderate, ensures easy demolding | PU, PVC, TPU material processing |

| Gloss | Matte/semi-matte | High-end leather, decorative materials |

| Thickness stability | ±2% | Hot pressing, coating processes |

Production Process and Technical Requirements

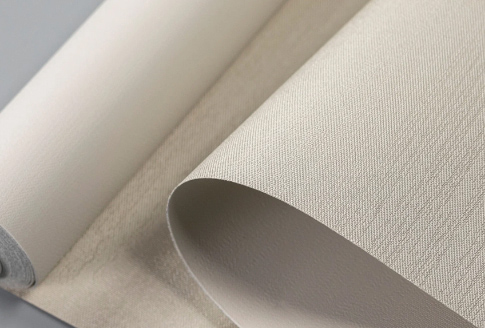

The production of high-temperature release paper involves multiple stages, including base paper selection, coating, drying, and surface treatment. Each step directly affects the final product’s performance. Anhui Honghuan New Material Technology Co., Ltd., as a comprehensive enterprise integrating R&D, production, and sales, has a complete production system and stable supply chain to ensure high consistency in product quality. The production process can be summarized as follows:

-

Base Paper Selection and Pre-treatment:

- Uses high-strength, heat-resistant coated paper or silicone-coated paper as the substrate;

- Smooths the base paper surface for uniform coating adhesion.

-

Coating and Surface Treatment:

- Advanced coating technology ensures even distribution of the release layer;

- Offers matte high temperature release paper or glossy variants according to customer requirements.

-

Drying and Curing:

- Continuous drying lines ensure complete curing of the coating;

- Precise temperature control prevents warping or cracking of the coating layer.

-

Testing and Grading:

- Equipped with pilot coating machines and advanced analytical instruments for precise quality control;

- Measures release force, heat resistance, gloss, and thickness to ensure batch-to-batch stability.

| Process Stage | Key Technical Points | Honghuan Advantage |

|---|---|---|

| Base paper pre-treatment | Smoothness, heat stability | Stable raw paper supply, precise dimensions |

| Coating process | Coating uniformity, thickness control | Automated coating equipment, multi-spec adaptation |

| Drying and curing | Temperature control, warp prevention | High-precision drying line, reliable stability |

| Testing and grading | Release force, heat resistance | Complete testing system, rapid customer response |

Applications of High-Temperature Release Paper

High-temperature release paper has a broad range of applications, especially in synthetic leather, hot-pressed decorative materials, and composite material production. Typical applications include:

-

Synthetic Leather Industry:

- Acts as a key material for hot-press molding and surface coating release;

- Honghuan has a specialized team in leather release paper, providing precise technical solutions.

-

Composite Material Processing:

- Prevents substrate adhesion in high-temperature hot pressing;

- Supports multi-layer material lamination, improving surface quality.

-

Packaging and Coating:

- Essential for PE-coated paper and specialty packaging requiring high-temperature release;

- Customizable sizes and specifications available from Honghuan.

| Application | Core Requirements | Product Advantage |

|---|---|---|

| Synthetic leather | Surface protection, demolding | Matte high temperature release paper, low adhesion, high heat resistance |

| Composite materials | Hot pressing, interlayer release | Dimensional stability, high-pressure resistance |

| Specialty packaging | High-temperature coating, thermal transfer | Custom specifications, OEM/ODM support |

Production Efficiency and Supply Chain Management

Production efficiency and supply chain stability are critical in the high-temperature release paper industry. Anhui Honghuan combines automated production lines with mature supply chain management to achieve high output and high quality:

- Production efficiency: Automated and semi-automated lines ensure high annual output;

- Flexible scheduling: Rapid adjustment of production plans for urgent orders;

- Stable supply chain: Reliable sourcing of base paper and chemical materials ensures uninterrupted production;

- Logistics: Extensive transportation experience ensures timely and safe delivery.

| Management Aspect | Key Strategy | Honghuan Practice |

|---|---|---|

| Production efficiency | Automation | High annual output, flexible scheduling |

| Raw material supply | Stability | Self-operated factories, continuous supply |

| Logistics | Safety and speed | Comprehensive logistics network, nationwide coverage |

| Customer service | Rapid response | Professional technical team, precise after-sales support |

Customization and Innovative Services

Diverse customer requirements drive the demand for customized high-temperature release paper. Honghuan demonstrates advantages in innovation and client services:

- Custom specifications: Widths from 1,600mm to 2,350mm, adjustable to client requirements;

- OEM/ODM services: Tailored solutions for unique processes;

- Low minimum order quantity: MOQ as low as 2,000 meters per roll, supporting small-scale production;

- Technical support: Expert team in leather release paper offering rapid-response after-sales service.

Conclusion

High temperature release paper, especially matte high temperature release paper, is not only a key material in modern manufacturing processes but also a core enabler for synthetic leather, composite materials, and specialty packaging industries. Through precise production processes, stable supply chains, expert technical teams, and flexible customization, companies can meet diverse market demands while ensuring consistent quality.

Copyright © Anhui Honghuan New Material Technology Co., Ltd. Rights Reserved.

Wholesale H518 Large Litchi Texture Matte High Temperature Release Paper Suppliers

English

English 中文简体

中文简体