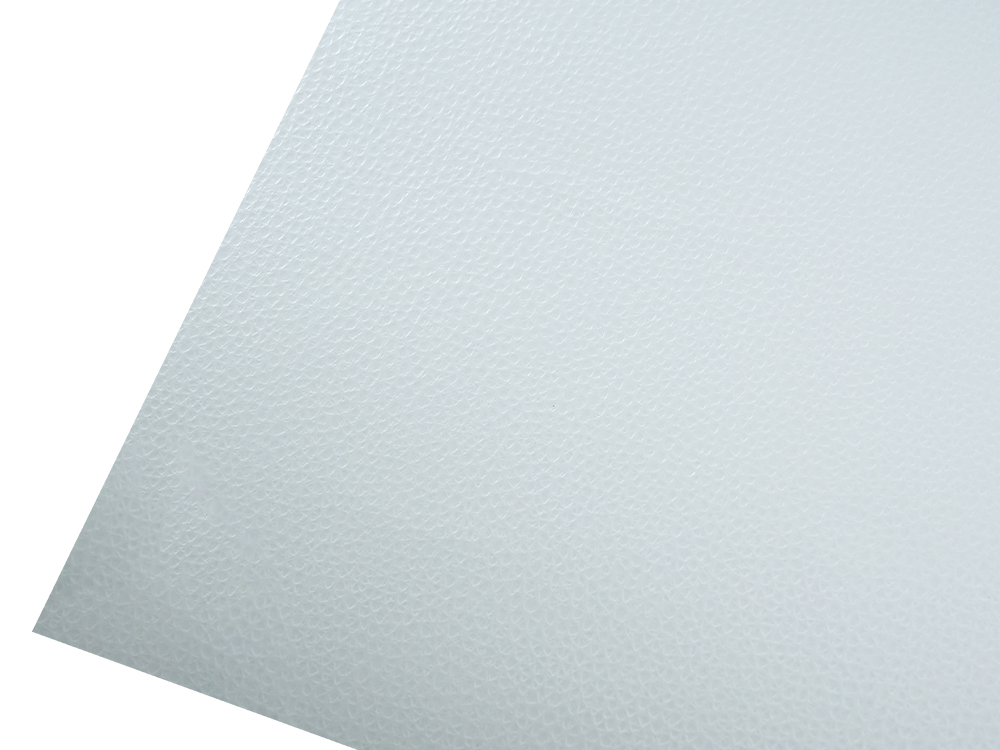

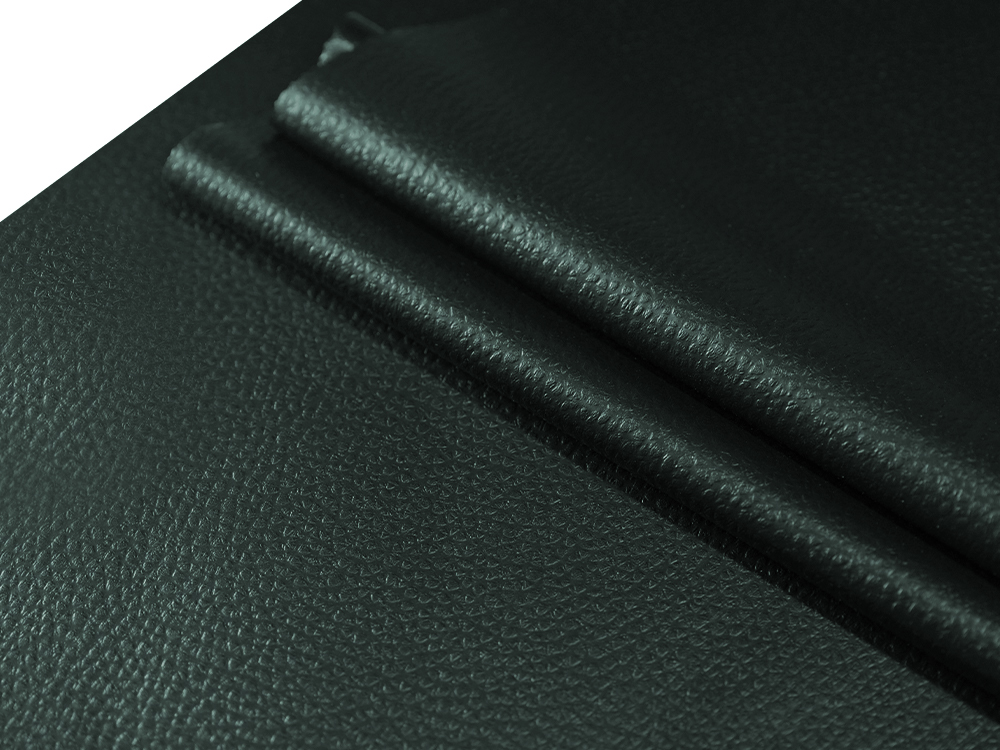

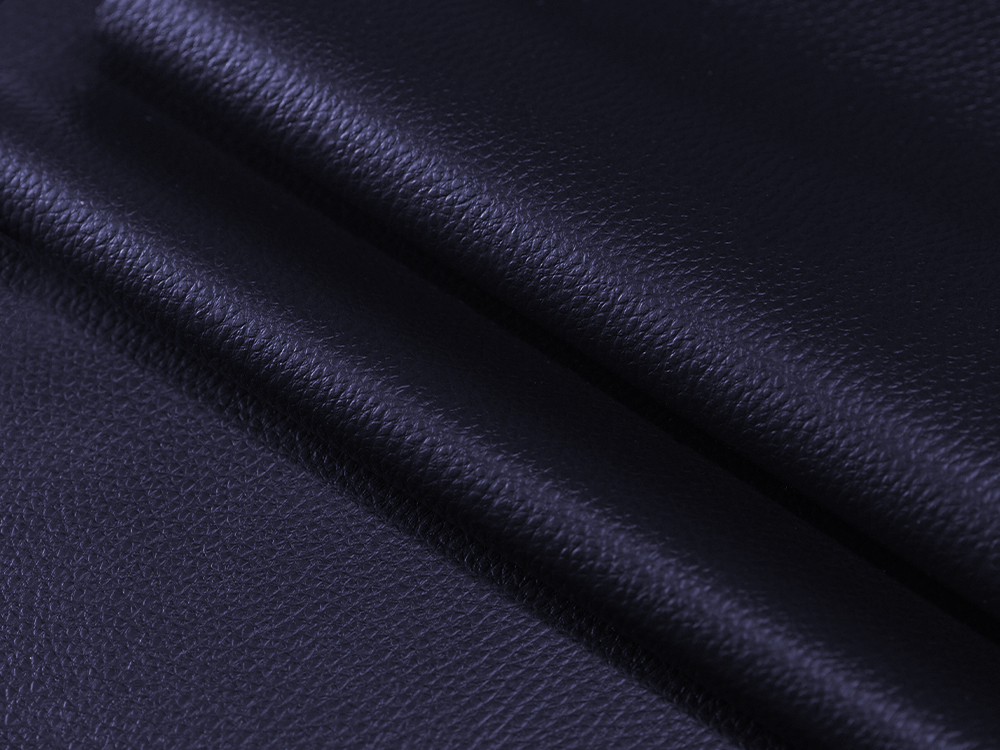

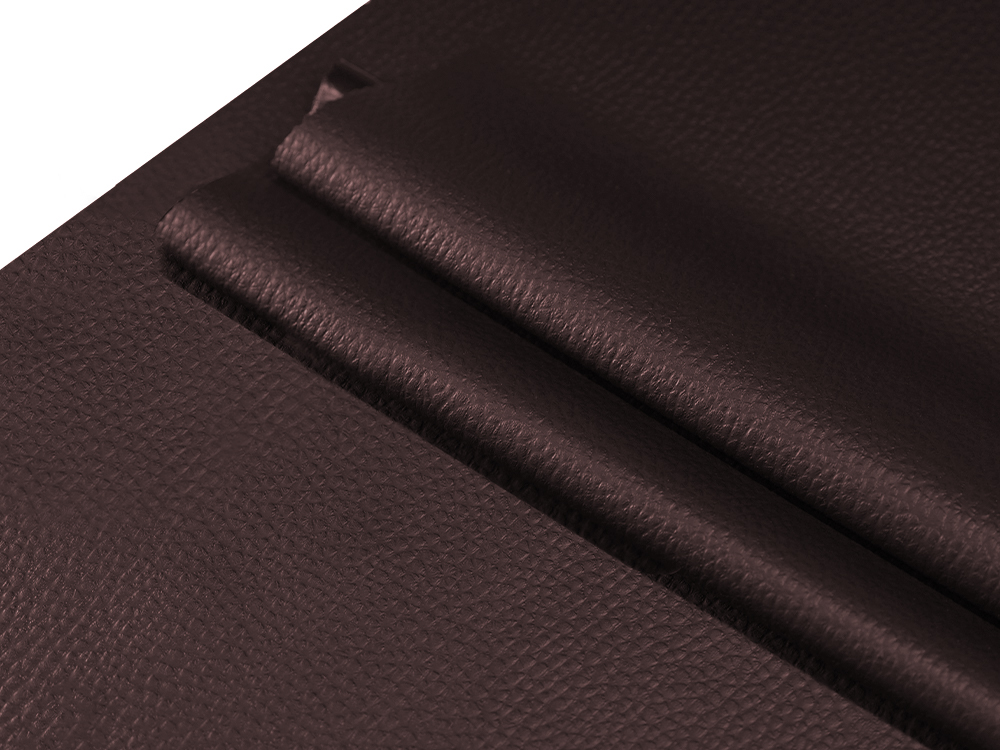

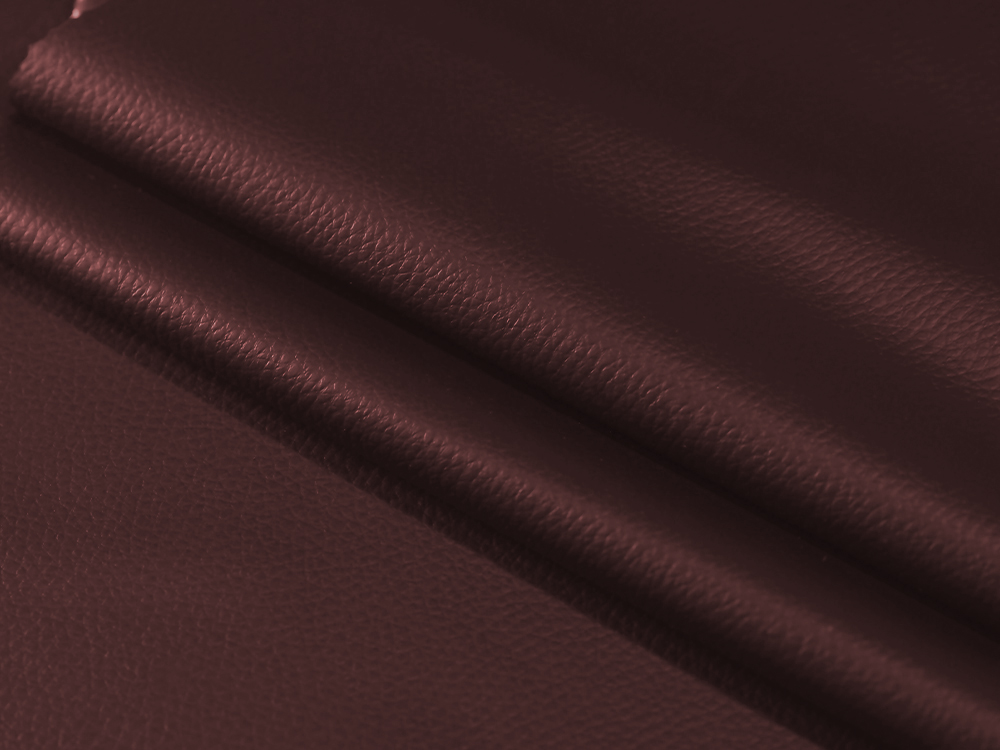

Honghuan high-temperature release paper is a high-performance anti-adhesive paper specially designed for synthetic leather production, with excellent heat resistance and durability. The leather surface produced with this release paper can present a unique lychee pattern with moderate glossiness, which is both beautiful and practical. It is suitable for the production of semi-glossy PVC and PU artificial leather. The paper is made of high-quality release backing paper and special silicon-based coating, which ensures the flatness and peeling performance of the paper. At the same time, it can be reused many times to meet the needs of efficient production.

Submit feedback

H558 Large Litchi Pattern Semi-bright High Temperature Release Paper

| Item | Details |

|---|---|

| Paper Specifications | Width customizable from 1500 mm to 2350 mm to suit diverse customer production needs. |

| High-Temperature Performance | Maintains excellent flatness, tension, folding resistance, and tear strength at 220℃, ensuring high-quality PVC leather production. |

| Surface Treatment | - Lychee grain embossing with moderate gloss. - Glossiness (75° angle): 40–50 (semi-gloss effect). |

| Release Force Adjustment | Adjustable to light release or heavy release for different PVC leather production requirements. |

| Durability & Reusability | - Semi-PU production: Reusable 50–60 times. - PVC production: Reusable 8–15 cycles. - Widely praised for reliability by users. |

| Surface Quality | Flat, smooth surface with uniform embossing, suitable for various pattern designs to meet diverse visual needs. |

Application areas: Honghuan's high temperature resistant release paper is widely used in many fields such as automotive interior leather, floor leather, sofa leather, luggage leather, etc. due to its excellent performance. It is especially suitable for the production of semi-gloss PVC and PU artificial leather, showing a high degree of flexibility and practicality.

Industry Knowledge Extension

Why Choose Semi-Bright High Temperature Release Paper for Composite Materials?

As industrial processes advance, traditional release papers often fail to maintain production efficiency and consistent quality under high-temperature conditions. High temperature release paper has therefore become an indispensable material in industries such as synthetic leather, composite films, adhesives, and coating materials. Among these, semi-bright high temperature release paper stands out for its heat resistance, surface gloss, and stability, making it widely applied in various high-temperature composite processes.

Definition and Characteristics

High temperature release paper is a type of industrial paper coated with specialized release materials, designed to withstand high temperatures and pressures while providing excellent release performance. Its main characteristics include:

- Heat Resistance: Can withstand continuous use at temperatures ranging from 150°C to 250°C or higher, suitable for hot pressing and baking processes.

- Release Stability: Uniform coating with moderate adhesion ensures smooth separation of materials during thermal processes, preventing sticking or surface damage.

- Surface Gloss and Smoothness: Semi-bright high temperature release paper combines moderate gloss with smoothness, ensuring both release performance and visual quality.

- Chemical Resistance: Resistant to acids, alkalis, and various solvents, making it suitable for coatings, adhesives, and other composite applications.

| Feature | Description | Application Value |

|---|---|---|

| Heat Resistance | Withstands 150°C–250°C | Suitable for hot pressing and composite material forming |

| Release Stability | Uniform coating, moderate adhesion | Ensures product integrity and mold release efficiency |

| Surface Gloss | Semi-bright finish | Meets industrial aesthetic and surface quality requirements |

| Chemical Resistance | Resistant to acids, alkalis, and solvents | Suitable for diverse chemical processes |

Manufacturing Process of High Temperature Release Paper

The production of high temperature release paper relies on high-quality base paper, precise coating technology, and strict quality control. Anhui Honghuan New Material Technology Co., Ltd. integrates R&D, production, and sales, demonstrating the key steps in manufacturing high temperature release paper:

-

Base Paper Selection and Treatment

High temperature release paper uses heat-resistant, high-tensile specialty paper as the base, which undergoes degreasing and smoothing to ensure uniform thickness before coating. Honghuan maintains a stable supply chain for base paper, ensuring reliable material sourcing. -

Coating Process

Using precision coating equipment, silicone or specialty polymers are evenly applied to the paper surface, forming a heat-resistant, easy-release layer. Coating thickness and uniformity directly affect release performance. -

Drying and Curing

Coated paper passes through a high-temperature drying system to cure the coating. Precise temperature control ensures adhesion and thermal resistance meet design specifications. -

Testing and Quality Control

Equipped with pilot coating machines, analytical instruments, and laboratories, Honghuan tests each batch for release force, heat resistance, surface gloss, and thickness uniformity to ensure consistent quality. -

Cutting and Rolling

Rolls are cut according to customer specifications, with widths ranging from 1,600 mm to 2,350 mm. Low minimum order quantities (2,000 meters per roll) provide flexibility for small-scale orders.

| Manufacturing Stage | Core Requirement | Implementation by Honghuan |

|---|---|---|

| Base Paper Treatment | Smooth, heat-resistant | Stable supply chain and processing capability |

| Coating Process | Uniform coating, proper adhesion | Automated coating production lines |

| Drying & Curing | Precise temperature control | Semi-automated high-temperature drying system |

| Quality Testing | Release force, gloss, thickness uniformity | Advanced lab equipment and analysis instruments |

| Cutting & Rolling | Customizable width and length | Supports low MOQ and multiple specifications |

Applications and Industry Value

High temperature release paper provides significant functional value across multiple industries:

-

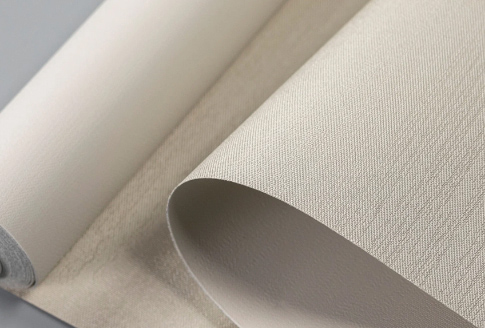

Synthetic Leather

In synthetic leather production, high temperature release paper is used for hot pressing and film transfer, ensuring the surface is free of adhesion and defects. Semi-bright high temperature release paper is preferred for high-end synthetic leather due to its balance of gloss and heat resistance. -

Composite Materials

During hot-pressing of composite panels and fiber-reinforced materials, release paper protects materials from sticking to molds while withstanding prolonged high temperatures, preserving structural integrity. -

Adhesives and Coating Processes

High temperature release paper resists heat-curing and baking processes, preventing adhesive residue on substrates and improving production efficiency. -

Specialty Packaging

In high-temperature packaging or thermal protection applications, release paper maintains dimensional stability and prevents contamination.

| Industry | Functional Value | Core Requirement |

|---|---|---|

| Synthetic Leather | Smooth, adhesion-free surface | Heat-resistant, semi-bright finish |

| Composite Materials | Protect molds and materials | High heat resistance, structural stability |

| Adhesives & Coatings | Prevent residue, improve efficiency | Stable release, chemical resistance |

| Specialty Packaging | Thermal protection, contamination prevention | Heat resistance, dimensional stability |

Quality Assurance and Service System

As a professional integrated enterprise, Anhui Honghuan New Material Technology Co., Ltd. provides comprehensive quality assurance and customer support:

-

Testing System

Advanced laboratories and coating test equipment ensure each batch meets release force, gloss, and thickness uniformity standards. -

Production Efficiency and Capacity

Combining automated and semi-automated production lines, Honghuan supports rapid delivery and flexible scheduling for urgent orders. -

Stable Production System

Complete manufacturing infrastructure and a reliable raw material supply chain ensure uninterrupted production regardless of market fluctuations. -

Customization Services

Supports OEM/ODM services, custom gloss levels, EMB designs, and adjustable specifications to meet diverse customer needs. -

Logistics and After-Sales Support

Comprehensive logistics and a responsive after-sales team guarantee safe and timely product delivery.

| Service Type | Description | Advantage |

|---|---|---|

| Testing | Release force, thickness, gloss | Reliable product quality |

| Customization | Gloss levels, EMB design, width | Meets diverse application needs |

| Production Capacity | Automated lines, high annual output | Rapid delivery and flexible scheduling |

| After-Sales & Logistics | Fast response, full support | Improves customer satisfaction |

The high temperature release paper is a critical component in modern industrial production, evolving toward high performance, environmental sustainability, and intelligent manufacturing. Semi-bright high temperature release paper combines heat resistance, stable release performance, and aesthetic surface quality, making it indispensable in synthetic leather, composites, adhesives, coatings, and high-temperature packaging.

Copyright © Anhui Honghuan New Material Technology Co., Ltd. Rights Reserved.

Wholesale H558 Large Litchi Pattern Semi-bright High Temperature Release Paper Suppliers

English

English 中文简体

中文简体