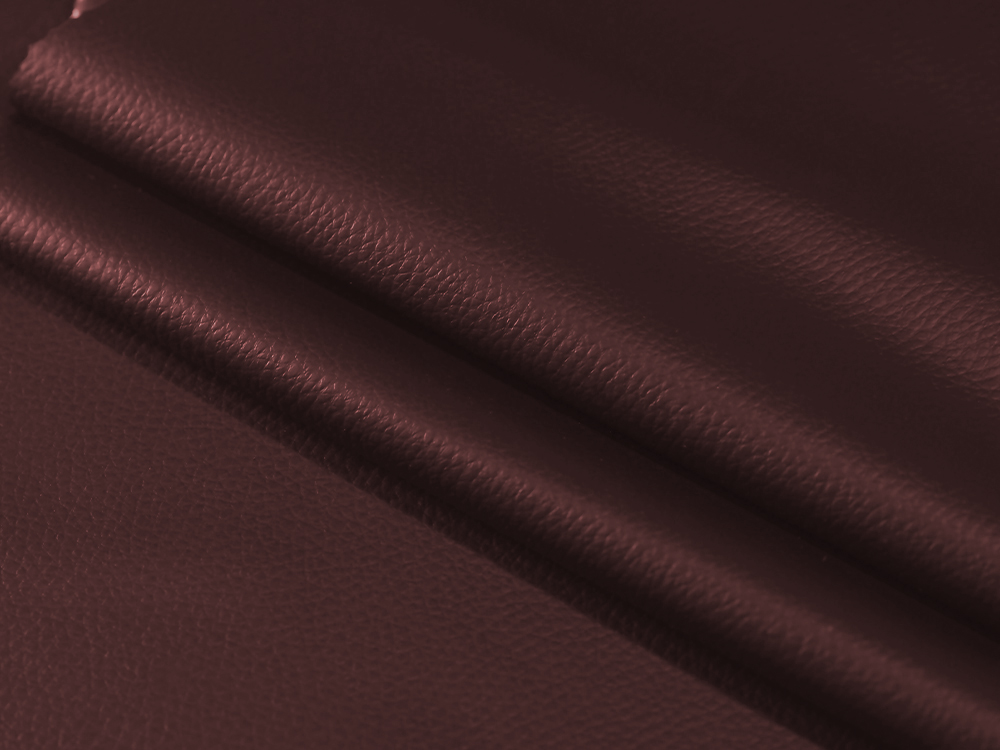

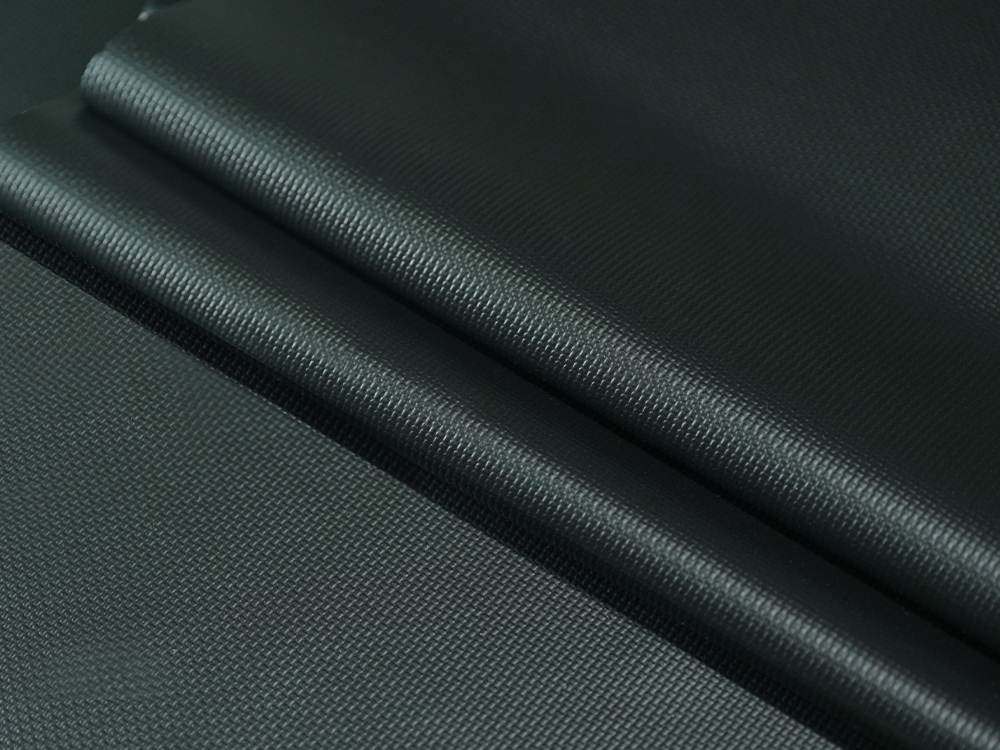

Honghuan high-temperature release paper is a kind of anti-adhesive paper specially designed for high-end artificial leather production. It is made of high-quality release paper and special silicon-based coating. It can make the leather surface into a delicate, small lychee texture and a super matte gloss effect. Its excellent flatness and durability make it an ideal choice for the production of PVC, PU, and other synthetic leathers. It can also be reused many times to meet the needs of environmental protection and the economy.

Submit feedback

H608 Small Litchi Pattern Super Matt High Temperature Release Paper

| Item | Details |

|---|---|

| Paper Specifications | Width customizable from 1500 mm to 2350 mm, adapting to diverse customer production needs. |

| High-Temperature Performance | Maintains flatness, tension, folding resistance, and tear strength at 220℃ in ovens, ensuring high-quality PVC leather production. |

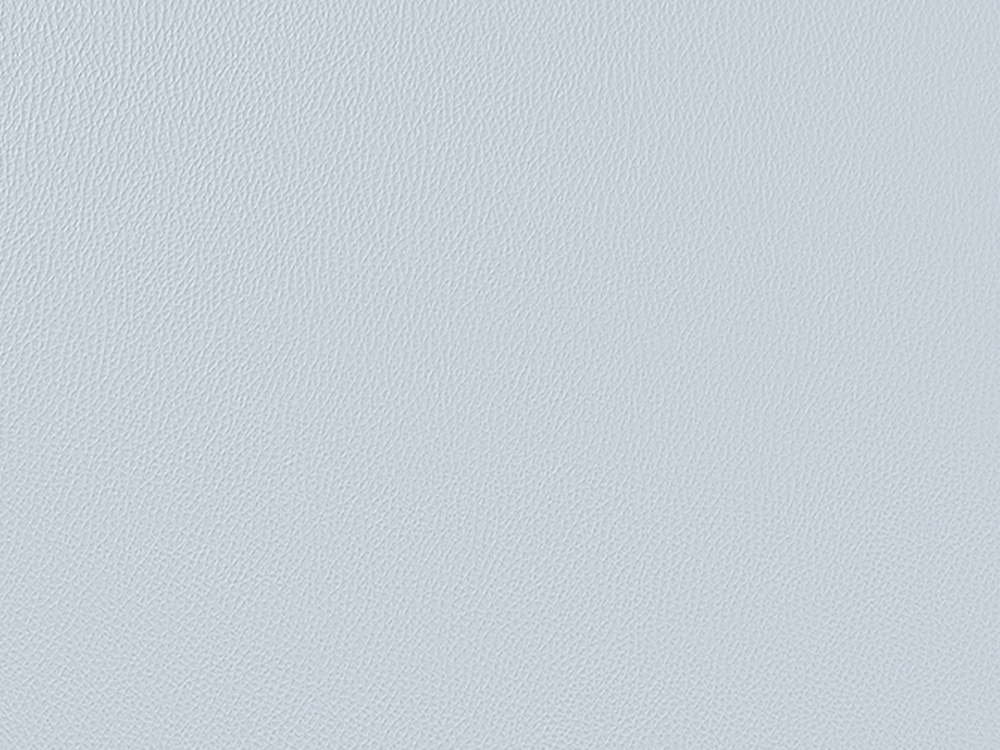

| Surface Treatment & Release Force | - Low gloss finish: Glossiness 5–10 (75° angle). - Adjustable release force: Light or heavy, catering to different leather processing requirements. |

| Durability & Reusability | - Semi-PU/PVC production: Reusable up to 50–60 times. - Widely praised by users for exceptional durability. |

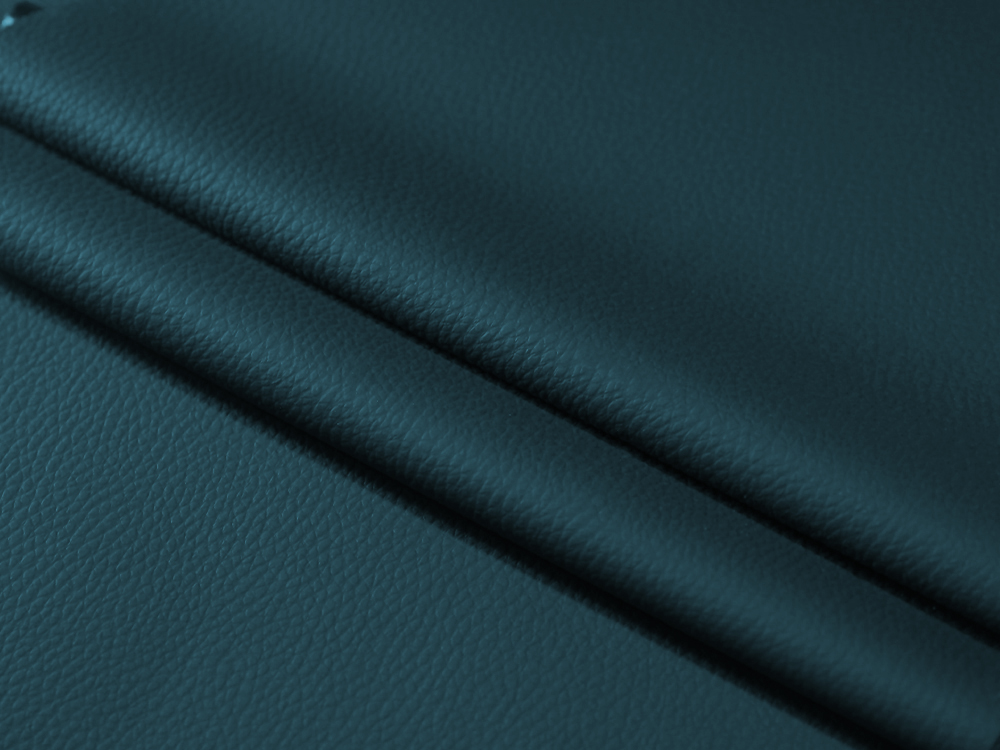

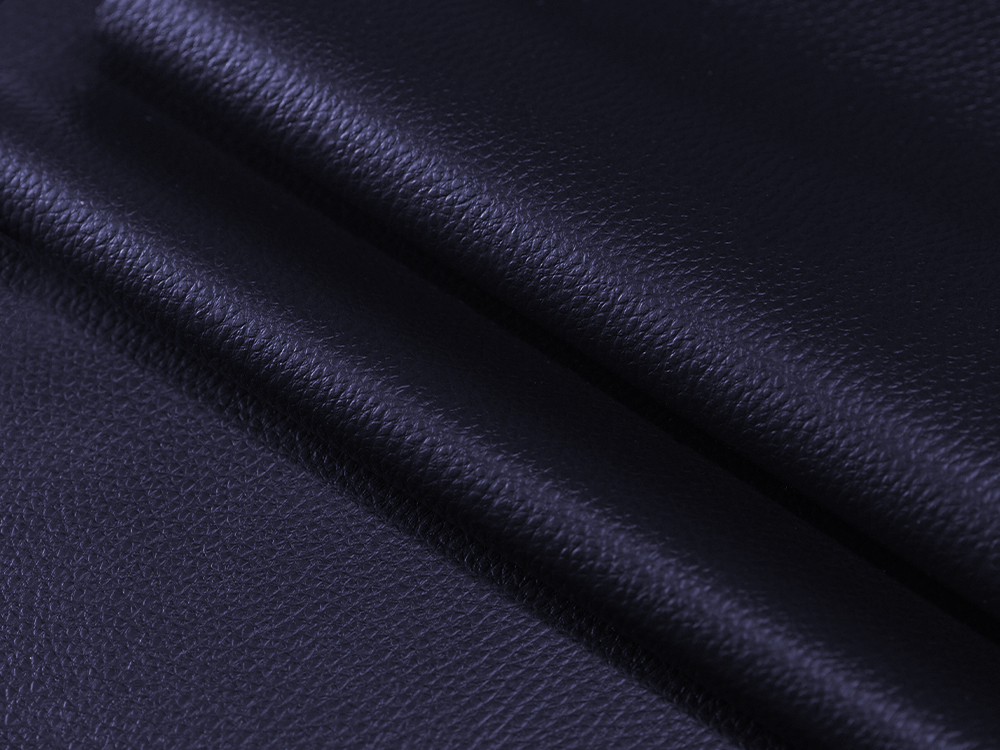

| Visual Design | Small lychee pattern design delivers a unique visual appeal, balancing practicality and aesthetics. |

Application areas: Honghuan's high-temperature resistant release paper is widely used in automotive interior leather, floor leather, sofa leather, and luggage leather due to its excellent performance. It is especially suitable for the production of high-end synthetic leather with high requirements on gloss and texture.

Industry Knowledge Extension

Industry Insights on High Temperature Release Paper

The demand for high temperature release paper continues to grow as industries such as tape manufacturing label production lamination composite materials electronics and automotive components increasingly require stable and reliable release performance. High temperature release paper ensures clean separation during processing and plays a key role in improving product quality and production efficiency.

What Is Release Paper and Why It Matters

Release paper also known as release liner or backing paper is used to protect pressure sensitive adhesive materials before use. It carries a special low surface energy coating allowing adhesives films or composite layers to be removed smoothly during processing. The performance of release paper including temperature resistance coating quality stability and peel strength directly affects the final product quality in many industrial applications.

About Our Product Advantages

Our product H608 Small Litchi Pattern Super Matt High Temperature Release Paper offers reliable performance and is suitable for various demanding industrial environments.

| Feature | Description |

| High Temperature Resistance | Designed for processes involving heat pressing laminating or die cutting while maintaining stable release performance. |

| Small Litchi Pattern and Super Matt Surface | The unique texture and matt surface offer improved appearance and are suitable for decorative and composite material processing. |

| Wide Application Range | Ideal for adhesive labels tapes composite films laminates decorative panels and industrial bonding processes. |

| Stable Quality and Customization | Specifications including base paper release force width and thickness can be customized to match customer requirements. |

| Strong Production Capacity | Supported by a modern facility integrated with research development production and sales ensuring stable supply and timely delivery. |

Typical Application Scenarios

- Adhesive labels tapes and double sided tapes

- Laminated boards decorative films and surface materials

- Composite film and protective film processing

- Electronics automotive and industrial component production

- High grade packaging and specialty lamination products

FAQ

Why not use ordinary kraft paper instead of release paper

Ordinary kraft paper does not offer stable release performance and cannot withstand higher temperatures or moisture. High temperature release paper provides consistent peel performance and dimensional stability during demanding industrial processes.

What is the benefit of the small litchi pattern and super matt surface

The textured and matt surface is valuable for decorative and composite material production where the surface appearance of laminated layers is important.

Can the release paper be customized based on my production needs

Yes. Base paper type coating release force width and surface effect can all be customized.

Is the product stable under high temperature and high pressure

The product is developed for environments requiring heat pressure and moisture stability and maintains consistent release performance.

How does high temperature release paper help reduce cost

It reduces defect rate improves production efficiency minimizes waste and ensures stable processing ultimately lowering total production cost.

How to Choose the Right Release Paper

- Identify your application and processing conditions

- Confirm performance requirements such as temperature resistance and release force

- Evaluate supplier stability and customization capability

- Consider long term efficiency and cost benefits

Conclusion

With strong research and production capabilities Anhui Honghuan New Material Technology Co Ltd provides high performance release paper solutions suitable for demanding industrial applications. Our product helps improve production stability enhance product quality and support various industries requiring reliable high temperature release performance.

Copyright © Anhui Honghuan New Material Technology Co., Ltd. Rights Reserved.

Wholesale H608 Small Litchi Pattern Super Matt High Temperature Release Paper Suppliers

English

English 中文简体

中文简体