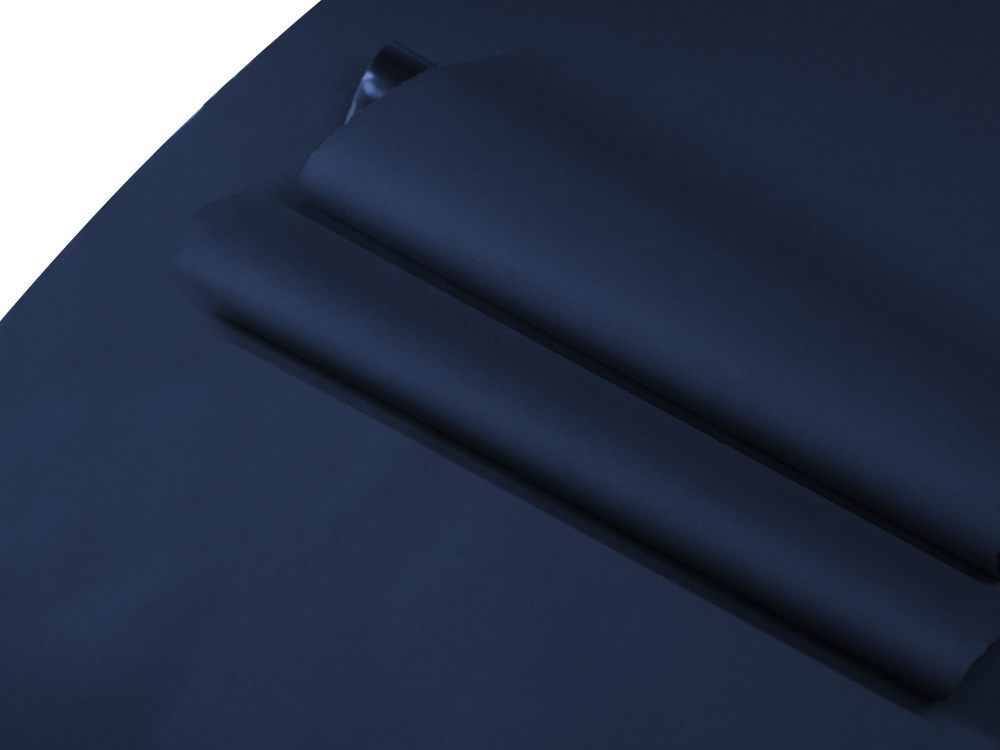

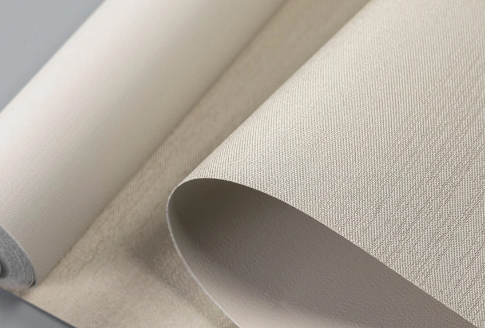

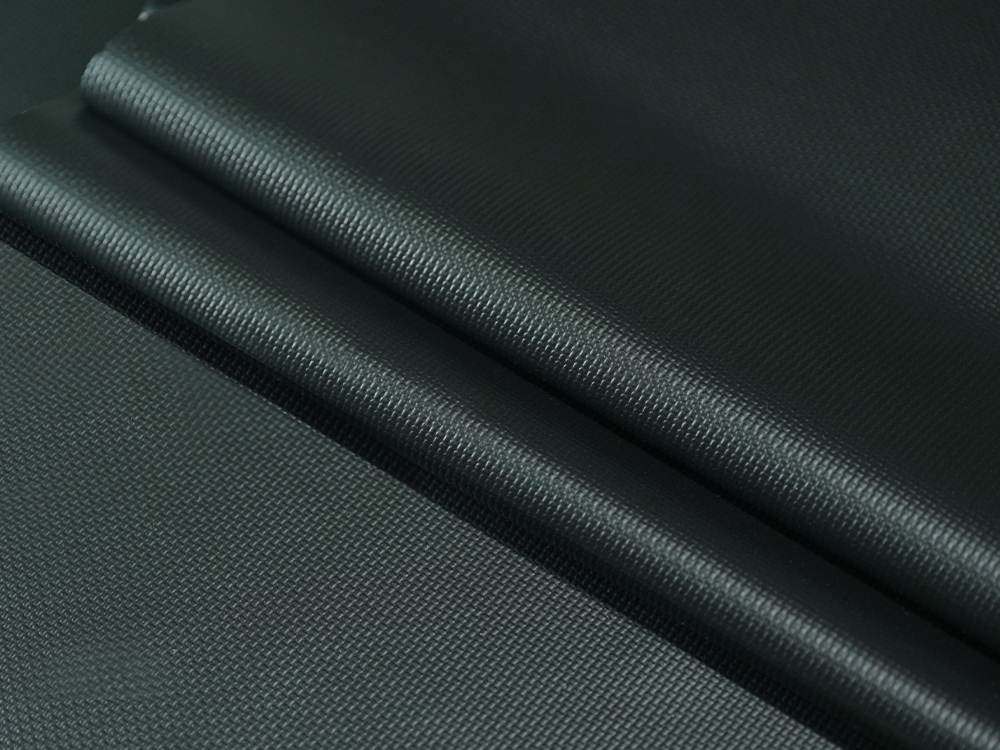

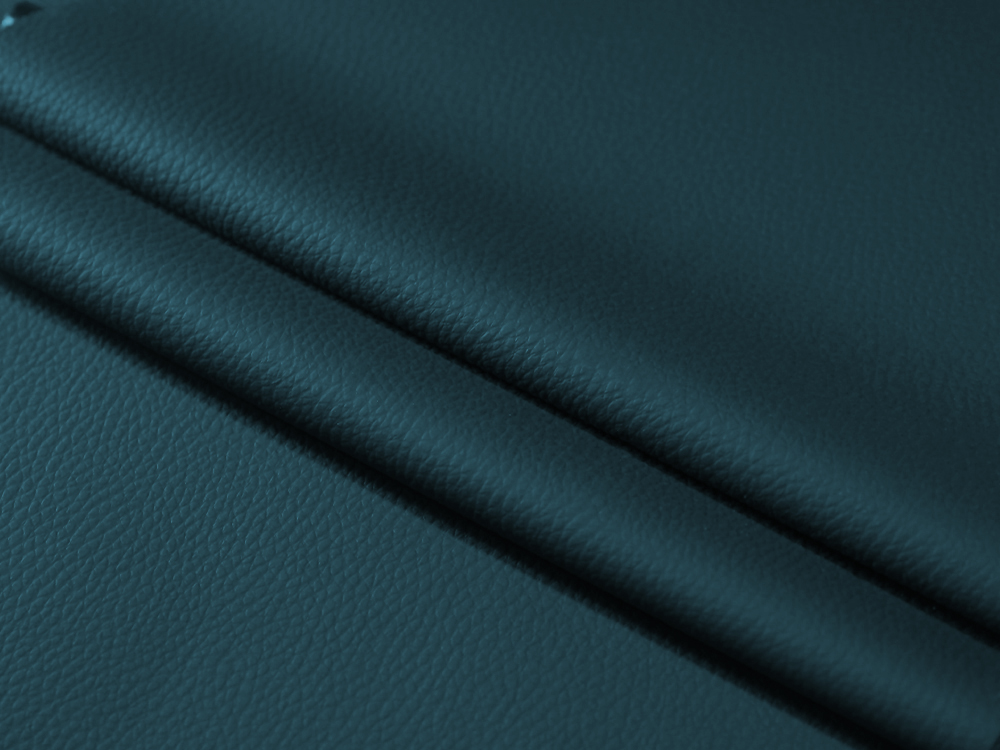

Honghuan high-temperature release paper is a special anti-adhesive paper used as a carrier for producing artificial leather and can be reused. It is made of high-quality release paper and a layer of special silicone-based coating, with good flatness and durability.

Submit feedback

H808 Plain Super Matt High Temperature Release Paper

| Item | Details |

|---|---|

| Paper Specifications | Adjustable from 1500 mm to 2350 mm to meet customized production needs. |

| High-Temperature Performance | Operates in an oven at 220℃, effectively maintaining paper flatness, tension, folding resistance, and tear strength to ensure high-quality PVC leather products. |

| Surface Treatment | - Produces plain paper with different glossiness levels. - Developed patterned paper with various textures to meet diverse visual effect requirements. |

| Release Force Adjustment | Can be adjusted to light or heavy release force to suit different PVC leather production needs. |

| Reusability | - Semi-PU production: Reusable up to 50–60 times. - PVC production: Reusable 8–15 cycles. - Widely praised for excellent durability and user feedback. |

| Glossiness (75°) | Only 5–10 units. |

Application areas: Honghuan's high temperature resistant release paper, with its excellent performance, meets the production requirements of semi-PU and PVC automotive interior leather, floor leather, sofa leather and luggage leather, etc., showing a high degree of flexibility.

Industry Knowledge Extension

Why are more and more new energy and composite material companies choosing H808 Plain Super Matt High Temperature Release Paper?

In an era of continuous upgrading in high-end manufacturing, materials technology is quietly becoming a key force driving industrial innovation. Among numerous functional materials, H808 Plain Super Matt High Temperature Release Paper is gradually becoming a new choice sought after by many industries. Its emergence not only improves production efficiency and process precision but also brings new possibilities to composite materials, new energy electronics, and automotive manufacturing. So, why has it stood out?

What makes H808 high-temperature release paper so "strong"?

Release paper is known as a "shadow material in the manufacturing process." It doesn't enter the final product but influences the success or failure of almost every key process. Especially in high-temperature curing, coating, lamination, and molding processes, the structural stability, surface condition, heat resistance, and peel uniformity of a sheet of paper can determine the final product quality.

H808 Plain Super Matt release paper has received high praise in manufacturing for its ultra-matte surface, high-temperature stability, and excellent dimensional retention. The ultra-matte finish makes it easier to control the surface condition in the production of optical and electronic materials; its high-temperature resistance prevents carbonization and brittleness during thermosetting, and reduces dimensional deviations caused by thermal expansion and contraction. This stability is invaluable for modern production processes that prioritize high yields.

More importantly, H808 peels off evenly and smoothly, without residue, tearing, or surface particle shedding. This means the production line can maintain continuous, high-speed, and trouble-free operation. For any company focused on production efficiency, this is an indispensable capability.

Why has high-temperature release paper suddenly become "essential"?

With the continuous expansion of the new energy, composite materials, and high-end electronics manufacturing sectors, process temperatures are generally rising. Whether it's photovoltaic encapsulation films, lithium battery separators, carbon fiber composite curing, or automotive interior molding, temperatures, pressures, and precision are all higher than before. This means that ordinary release paper can no longer meet production requirements, and industries must find more durable materials to support their processes.

In this context, high-temperature release paper has gradually transformed from a niche demand into a "standard material." It not only serves a separating function but also influences the uniformity of material curing, the smoothness of the product surface, the smoothness of coating, and the stability of processing. In other words, release paper is no longer just an accessory but a key factor determining performance.

This is precisely why H808 release paper has gained rapid attention—it fully meets the higher demands of the new industrial era for efficiency, stability, and yield.

Why are more and more companies choosing Anhui Honghuan New Material Technology Co., Ltd.'s H808?

In the high-temperature release paper market, Anhui Honghuan New Material Technology Co., Ltd. has been a particularly outstanding force in recent years. Located in Shitan Industrial Park, Quanjiao County, Chuzhou City, Anhui Province, the company covers an area of 58 acres and is adjacent to highways, railways, and airports, possessing natural logistical advantages. Convenient transportation ensures faster and more efficient delivery from raw material supply to customers, enabling the company to respond to customer project needs in a shorter cycle.

More importantly, Anhui Honghuan New Material Technology Co., Ltd. possesses mature R&D capabilities and a complete production system. From release paper substrate treatment to surface technology control, from coating process optimization to high-temperature resistance research and development, the company has always adhered to technology-driven development. As early as 2019, Anhui Honghuan New Material Technology Co., Ltd. successfully developed high-temperature release paper independently, filling the gap in China's reliance on imports for some high-specification materials. This research achievement not only validated its technological strength but also solidified Honghuan's professional position in the industry.

At the production level, the company is equipped with advanced equipment, enabling strict control over coating thickness, release force, and paper stability, ensuring consistent product performance even under large-scale production. This stable output capability allows Anhui Honghuan New Material Technology Co., Ltd.'s H808 release paper to adapt to various precision industrial environments, truly achieving "stability from the start."

In which key industries is H808 high-temperature release paper being used?

H808 Plain Super Matt high-temperature release paper has a wide range of applications. It is used for coating and curing photovoltaic module encapsulation materials, is an important auxiliary material in the production of lithium battery separator films and tape substrates, and plays an irreplaceable role in the manufacturing of carbon fiber composites, automotive interior hot pressing, and electrical insulation materials.

In these industries, the processes have extremely high requirements for temperature, pressure, stability, and controllability, and H808 release paper demonstrates its advantages in meeting these challenges. Especially in the fields of composite materials and new energy manufacturing, it has gradually become the preferred material for enterprise standardization.

FAQ: Regarding H808 Plain Super Matt high-temperature release paper, you may also want to know:

Q1: What level of temperature resistance can H808 achieve?

A: H808 exhibits stability under high-temperature curing and high-pressure thermoforming conditions, making it suitable for various processes requiring environments above 200℃, and it is not prone to carbonization or brittleness.

Q2: Is it suitable for new energy fields such as photovoltaics and lithium batteries?

A: Absolutely. H808 demonstrates excellent stability and peel consistency in film coating, separator processing, and photovoltaic lamination.

Q3: What are the advantages of Anhui Honghuan New Material Technology Co., Ltd. compared to ordinary suppliers?

A: Anhui Honghuan New Material Technology Co., Ltd. possesses a complete R&D system, high-standard production lines, strict quality control, and large-scale stable production capacity. It also boasts excellent transportation and logistics conditions, enabling rapid response to enterprise needs.

Q4: What are the benefits of the matte surface of H808 for special processes?

A: The ultra-matte structure helps avoid reflective interference and surface unevenness, resulting in better performance in optical, electronic, and precision composite material manufacturing.

Q5: Can the product be customized?

A: Honghuan supports customization of multiple parameters, including release force, thickness, and substrate type, which can be personalized according to the process requirements of different industries.

Copyright © Anhui Honghuan New Material Technology Co., Ltd. Rights Reserved.

Wholesale H808 Plain Super Matt High Temperature Release Paper Suppliers

English

English 中文简体

中文简体