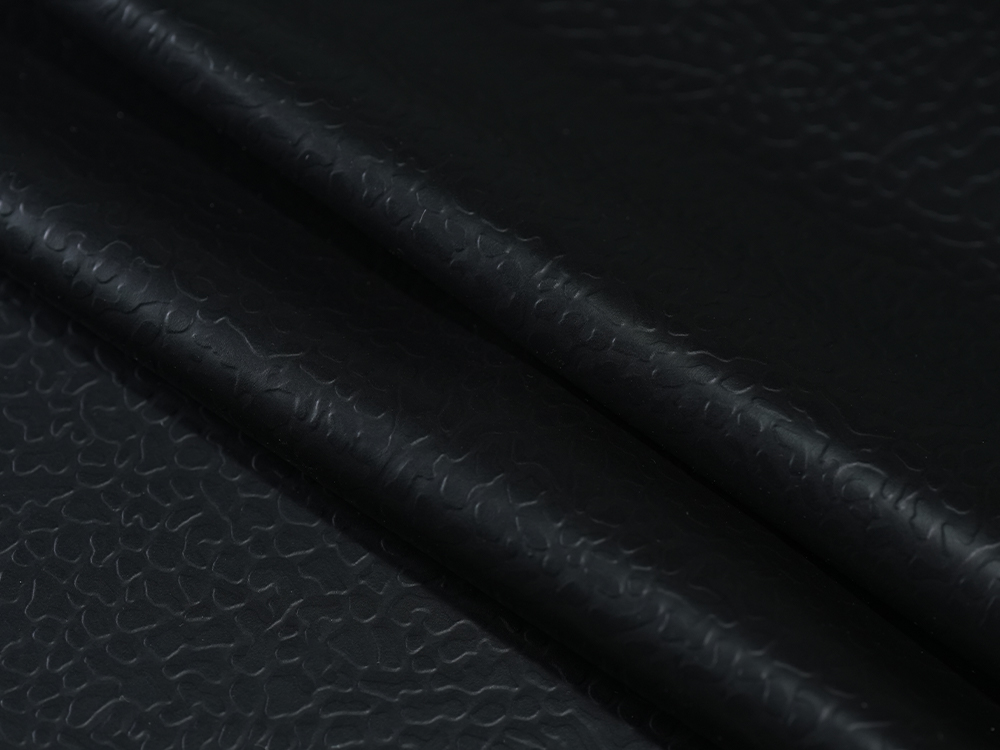

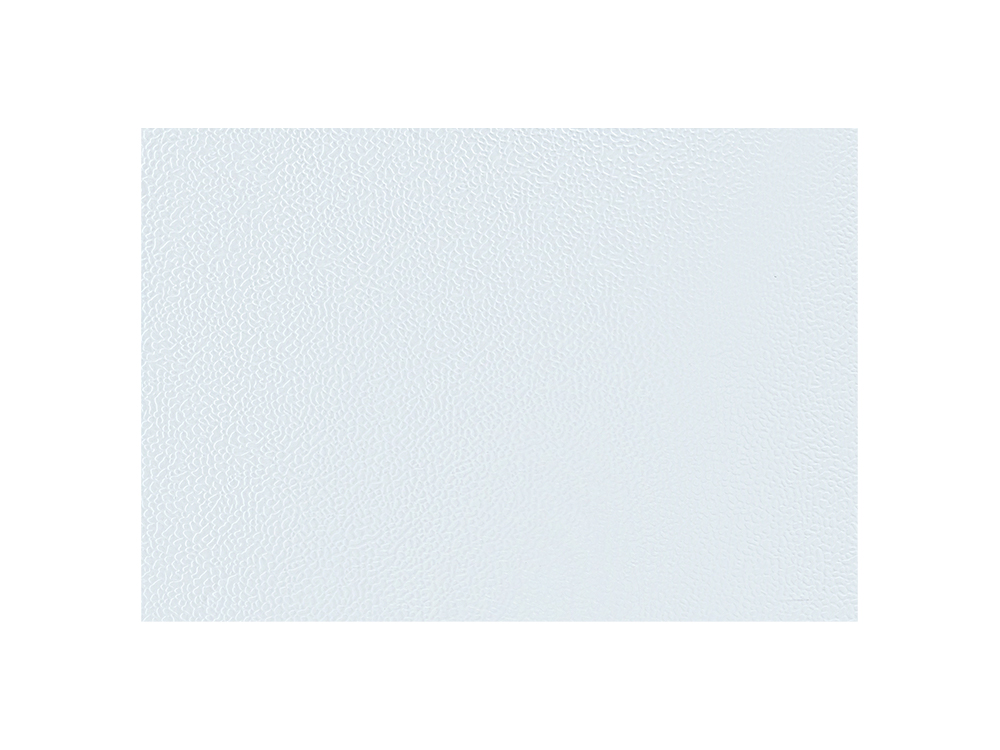

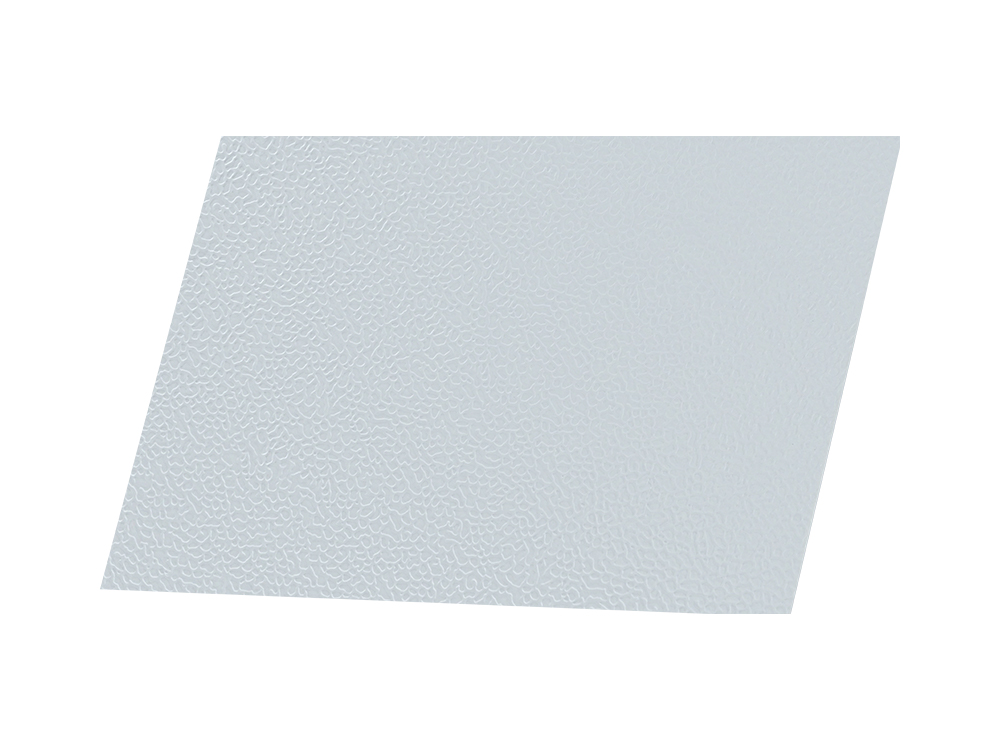

Honghuan high-temperature release paper is a kind of anti-adhesive paper designed for high-end artificial leather production. It is made of high-quality release paper combined with special silicone-based coating, and has excellent flatness and durability. The leather surface produced with this release paper can present a unique gemstone texture with extremely low gloss (gloss at 75° angle is only 5-10), meeting the demand for ultra-matte effect. This product has both light release force and heavy release force adjustment functions, suitable for different types of PVC leather production, and has excellent reusability. It can be reused up to 50~60 times in semi-PU production and 8~15 times in PVC production.

Submit feedback

H308 Gemstone Super Matt High Temperature Release Paper

| Item | Details |

|---|---|

| Paper Specifications | Width customizable from 1500 mm to 2350 mm to fit different production lines and customer needs. |

| High-Temperature Performance | Maintains flatness, tension, folding resistance, and tear strength in a 220℃ oven, ensuring high-quality PVC leather production. |

| Surface Treatment | - Offers diverse gloss options. - Features gemstone pattern designs to meet diverse visual effect requirements. |

| Release Force Adjustment | Adjustable to light release or heavy release for different PVC leather types, with excellent peeling performance. |

| Durability & Reusability | - Semi-PU production: Reusable up to 50–60 times. - PVC production: Reusable 8–15 times. - Widely recognized for reusability by users. |

| Gloss Performance | Low gloss level of 5–10 at a 75° angle, delivering a unique matte texture to products. |

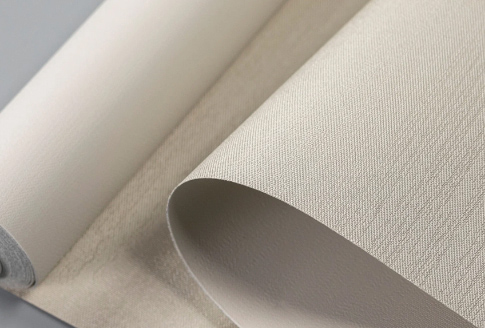

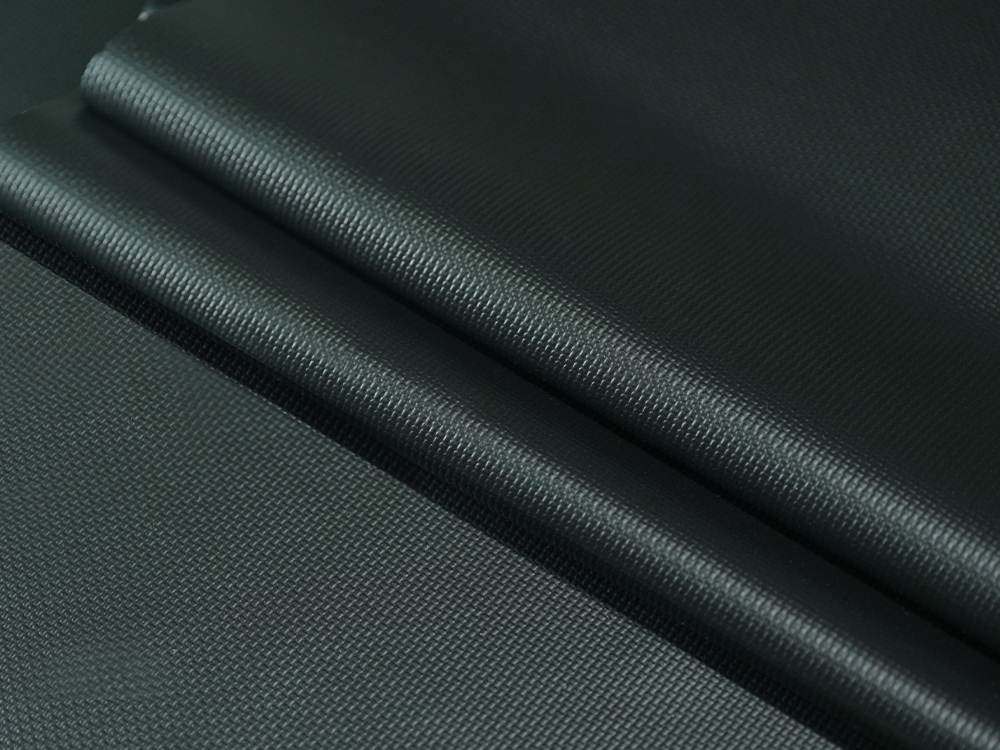

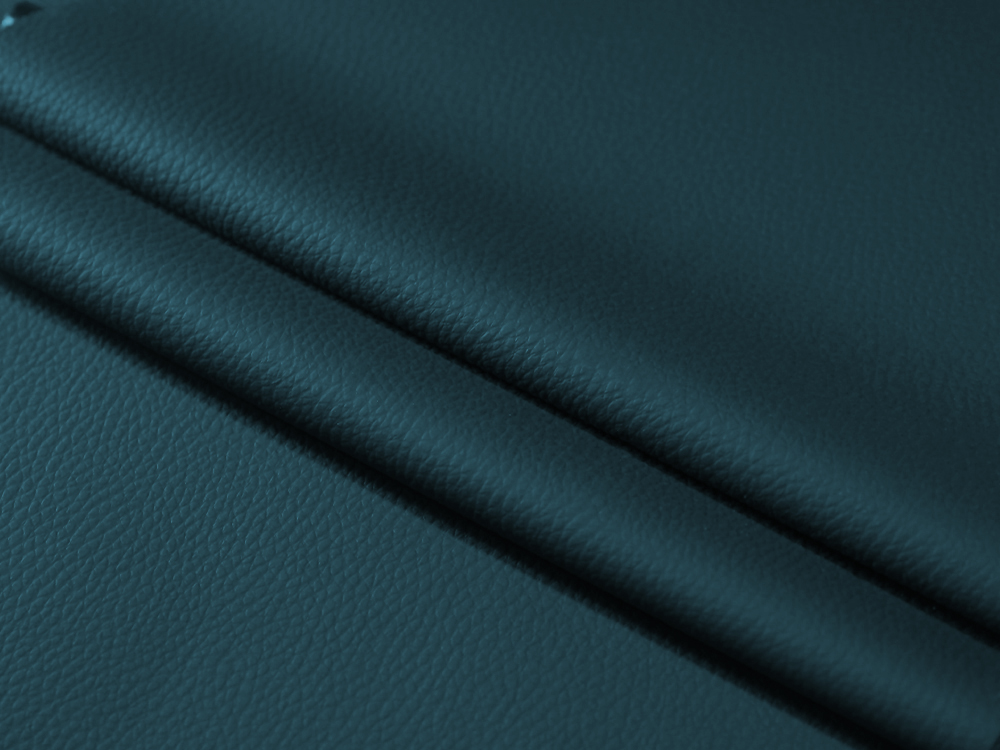

Application fields: Honghuan's high-temperature resistant release paper is widely used in semi-PU and PVC automotive interior leather, floor leather, sofa leather, luggage leather, and other fields due to its excellent performance. With its unique gemstone texture and super matte gloss, this product not only improves the aesthetics of the product but also meets the diversified needs of the high-end market, showing a high degree of flexibility and practicality.

Industry Knowledge Extension

How does high temperature release paper ensure stable texture formation?

High-temperature release paper has become a foundational material in the processing of composite structures, synthetic leather, functional films, and specialty packaging. Its core value lies in thermal stability, controlled surface structure, consistent release performance, and compatibility with various resin systems.

Material Fundamentals and Structural Logic of High-Temperature Release Paper

High-temperature release paper is typically composed of a specialty base paper coated with high-temperature silicone systems or functional polymer layers, enabling stable demolding under high heat, high pressure, and continuous production. Its structure generally includes:

- Base Paper – Provides mechanical strength, dimensional stability, and heat resistance.

- Pre-Coating Layer – Enhances bonding between the base paper and the functional coating.

- Functional Coating Layer – Delivers release performance, anti-stick behavior, and surface texture transfer.

Depending on the application—such as dry/wet PU synthetic leather, thermal curing composites, or cast film processes—the required thermal resistance typically ranges from 130°C to above 180°C. Thus, the coating’s crosslinking density, anti-yellowing stability, and thermal endurance are crucial indicators of performance.

Surface Structure Control and Texture Reproduction

Beyond release functionality, high-temperature release paper serves as the “master surface” for texture formation. Gem-grade ultra-matte high-temperature release paper uses a precision embossing process to create an ultra-low gloss, uniform matte effect and delicate touch, helping synthetic leather achieve a high-end aesthetic and tactile feel comparable to natural materials.

Below is a structured overview of common surface types:

| Surface Type | Gloss Level | Tactile Features | Representative Applications |

|---|---|---|---|

| Super Matt | Ultra-low | Soft, fine | High-end PU leather, automotive interiors |

| Semi Matt | Low to medium | Smooth | Technical films, specialty packaging |

| High Gloss | High | Polished, mirror-like | Glossy synthetic leather, decorative films |

| Texture Grain | Adjustable | Fine to coarse | Footwear leather, furniture leather |

Texture uniformity is heavily dependent on coating levelling behavior and embossing accuracy—core competencies of advanced release-paper manufacturers.

Thermal Stability and Processing Compatibility

High-temperature release paper must perform reliably across diverse processing environments, including:

- Wet and dry PU synthetic leather calendaring

- Thermal-curing resin composite demolding

- Cast-film extrusion or hot-press lamination

- Specialty coating and surface finishing processes

Its key performance indicators include:

- Thermal Dimensional Stability – No deformation, shrinkage, or warping under repeated heat cycles.

- Anti-Yellowing Properties – Maintains surface color and chemical integrity under prolonged heat exposure.

- Consistent Release Performance – Prevents adhesion, residue, or surface defects during repeated use.

- Texture Accuracy – Maintains uniform pattern depth and clarity during high-speed production.

Manufacturing Technology and Process Control

Producing high-temperature release paper requires precise control over base-paper densification, coating uniformity, curing crosslinking, and embossed surface replication. This places high demands on equipment, process engineering, and quality assurance systems.

Anhui Honghuan New Material Technology Co., Ltd., a comprehensive enterprise integrating R&D, production, and sales, exemplifies a technology-driven approach in this field. Honghuan specializes in release paper, PE-coated paper, and various specialty packaging materials, offering high-efficiency after-sales support through a team of experts in leather release paper.

Detection

Honghuan is equipped with advanced testing instruments—such as pilot coating machines and analytical devices—to ensure accurate measurement of coating thickness, surface energy, thermal performance, and texture fidelity. This ensures stable and repeatable product quality.

Efficiency

The company operates with strict cycle-time control throughout design, development, and mass production. Flexible scheduling is available for urgent orders, ensuring that delivery speed aligns with customers’ fast-paced manufacturing cycles.

Production Capability

Automated and semi-automated production lines significantly enhance coating stability, embossing consistency, and overall output capacity. This ensures both high yearly output and the ability to meet diverse specification requirements.

Honghuan’s technical team provides rapid-response and precise after-sales support—covering product selection, texture development, process optimization, and troubleshooting within the synthetic leather industry.

Structural Overview of Core Application Systems

To illustrate the functional role of high-temperature release paper more clearly, the table below categorizes typical application scenarios:

| Application Area | Key Requirements | Function of High-Temperature Release Paper |

|---|---|---|

| PU/PVC Synthetic Leather | High thermal stability; clear textures; consistent demolding | Texture replication; surface formation; anti-adhesion |

| Functional Films | High flatness; high cleanliness | Supports casting; improves surface quality |

| Thermoset Composites | Heat resistance; no residue | Provides clean demolding and surface protection |

| High-End Packaging | Consistent surface appearance; durable coatings | Controls surface patterns and release behavior |

The gemstone super matt high temperature release paper is especially well-suited for automotive interior leather, footwear uppers, and premium fashion materials due to its ultra-matte effect and stable tactile properties.

Industry Trends: From High Heat Resistance to Multifunctionality

The development of high-temperature release paper is evolving toward greater material sophistication and environmental responsibility. Current industry directions include:

- Higher Heat Resistance & Lower Thermal Shrinkage

Supports new high-temperature, high-efficiency processing lines. - Multifunctional Coatings

Anti-static, anti-fouling, low-haze, and self-cleaning capabilities. - Environment-Oriented Manufacturing

Water-based coating systems, high-solids formulations, and recyclable base materials. - Precision Surface Engineering

Ultra-fine matte, micro-texture, and high-fidelity tactile reproduction. - Digitalized Quality Control

Real-time monitoring of gloss, coating thickness, and texture parameters.

Conclusion

High-temperature release paper has evolved from a simple release medium to a critical functional interface that shapes the appearance, texture, and performance of synthetic leather, functional films, and composite materials.

Copyright © Anhui Honghuan New Material Technology Co., Ltd. Rights Reserved.

Wholesale H308 Gemstone Super Matt High Temperature Release Paper Suppliers

English

English 中文简体

中文简体