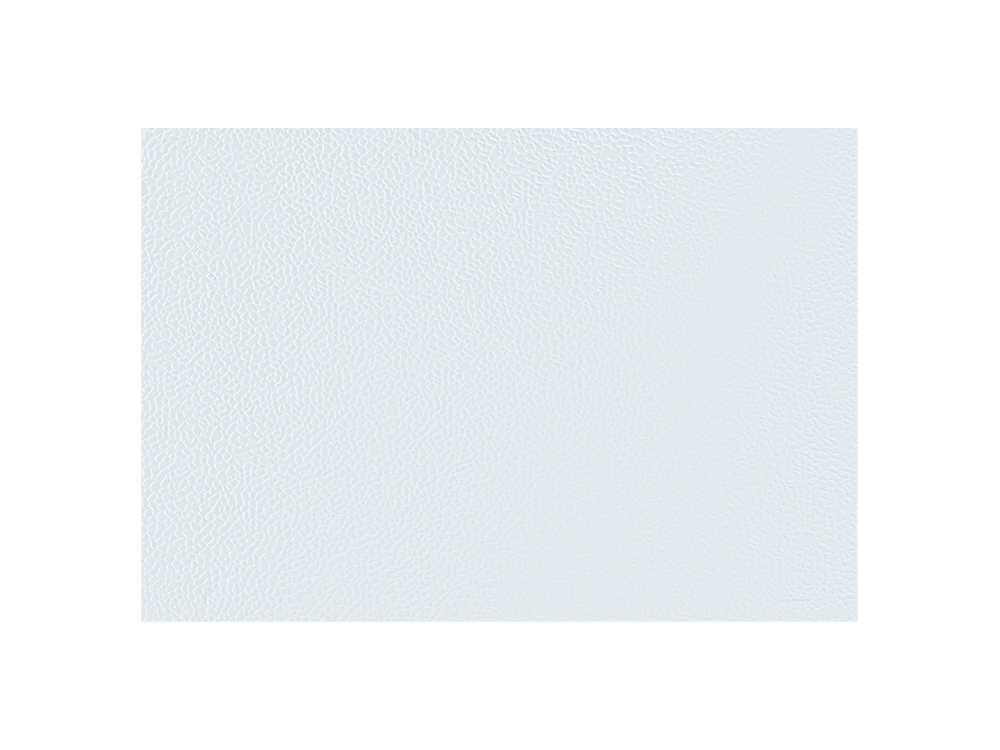

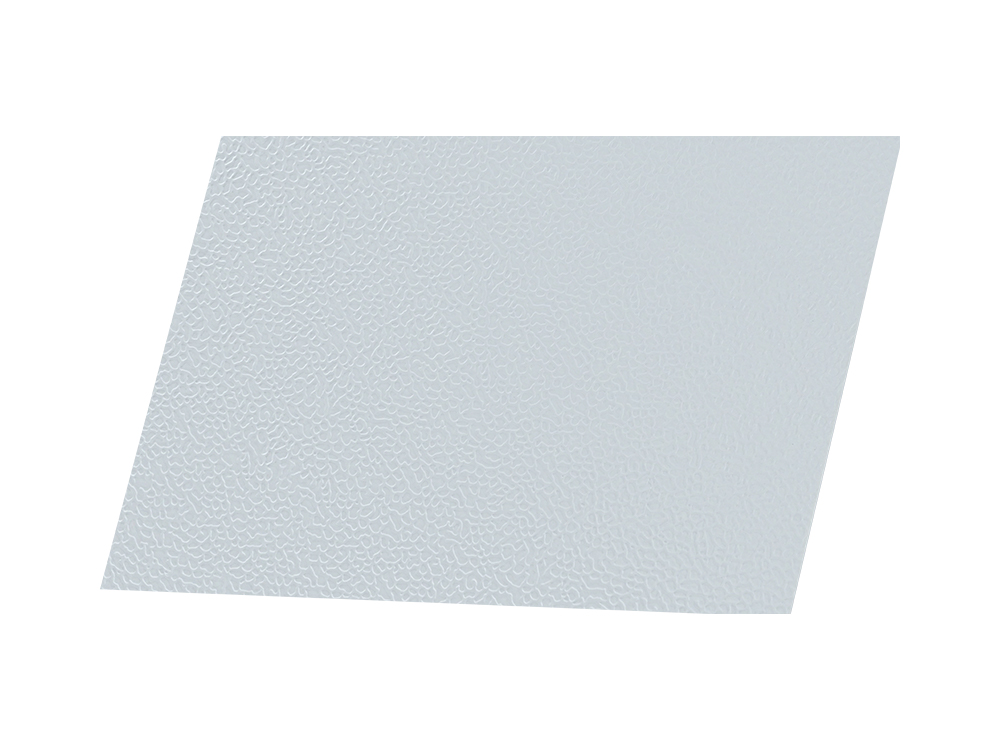

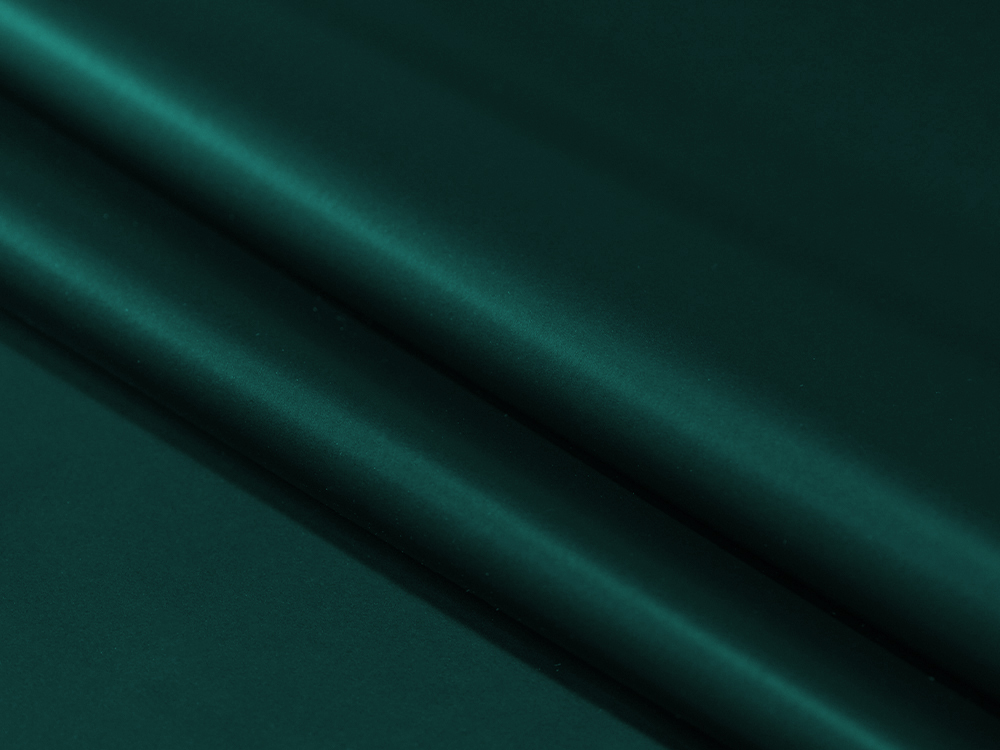

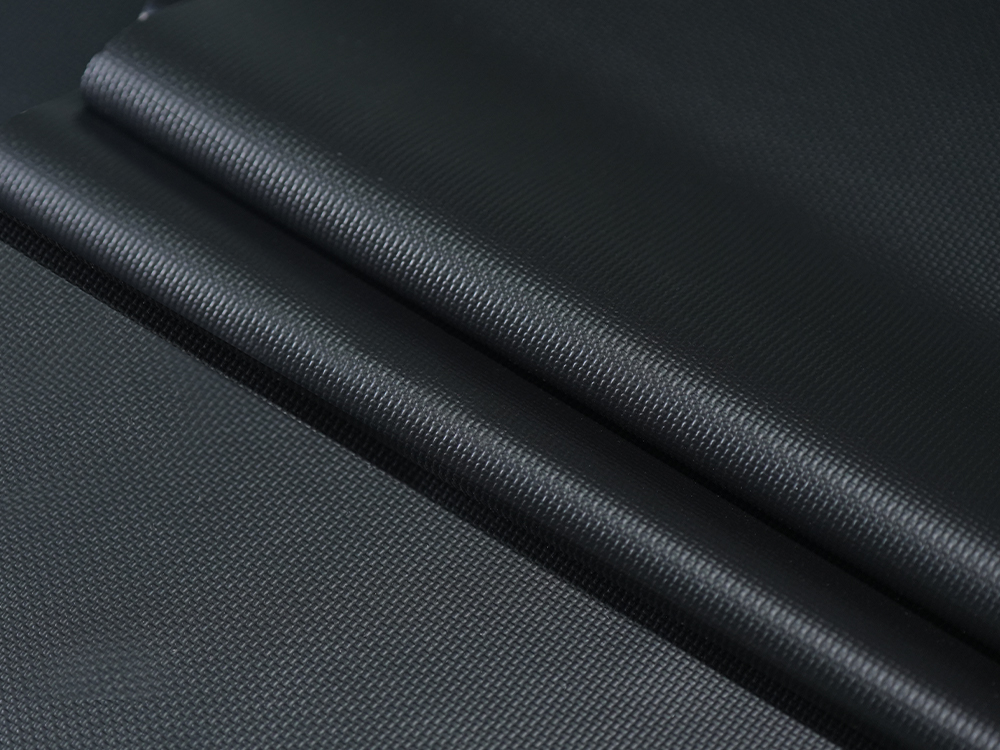

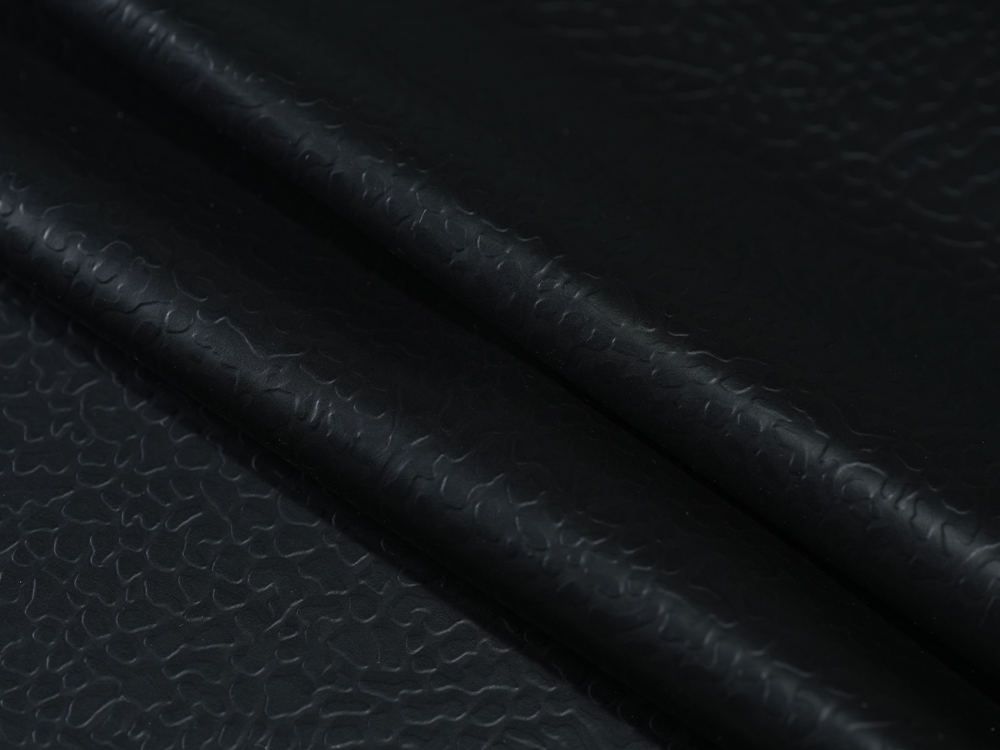

Honghuan high-temperature release paper is a kind of anti-adhesive paper specially designed for high-end artificial leather production. It is made of high-quality release paper and special silicon-based coating. The leather surface produced with this release paper can present a unique gemstone matte effect. Its excellent flatness and durability make it an ideal choice for PVC and semi-PU artificial leather production. It also has good reusability and meets environmental protection and economic requirements.

Submit feedback

H318 Gemstone Matte High Temperature Release Paper

| Item | Details |

|---|---|

| Paper Specifications | Width is customizable from 1500 mm to 2350 mm to meet diverse customer production needs. |

| High-Temperature Performance | Maintains flatness, tension, folding resistance, and tear strength in a 220℃ oven, ensuring high-quality PVC leather production. |

| Surface Treatment | - Unique gemstone effect design. - Offers multiple gloss levels to cater to diverse visual requirements. |

| Release Force Adjustment | Adjustable to light release or heavy release for different PVC leather production requirements, with reliable peeling performance. |

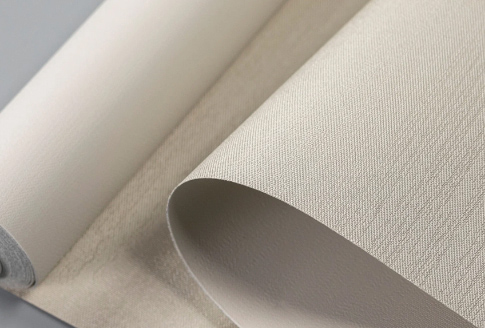

| Durability & Reusability | - Semi-PU production: Reusable 50–60 times. - PVC production: Reusable 8–15 times. - Widely praised by users for reusability. |

| Gloss Performance (75° Angle) | Gloss level of 10–20, delivering a prominent matte effect suitable for high-end product needs. |

Application areas: Honghuan's high temperature resistant release paper is widely used in automotive interior leather, floor leather, sofa leather and luggage leather due to its excellent performance. It is especially suitable for the production of synthetic leather products that pursue high-end texture and visual effects. Its high degree of flexibility and durability make it ideal for high-end artificial leather manufacturing.

Industry Knowledge Extension

How Does High Temperature Release Paper Ensure Precision in High-Heat Applications?

High temperature release paper is a functional industrial material whose technical threshold, process adaptability, and stability directly determine the quality of end products. In synthetic leather, electronics, adhesive systems, and high-temperature processing, release paper is far more than a surface barrier—it is an essential carrier for texture replication, surface control, dimensional stability, and production efficiency.

Functional Attributes and Material System of High Temperature Release Paper

High temperature release paper is typically composed of a base paper, a coating structure, and functional resin systems. The base paper provides mechanical strength and dimensional stability; the release layer determines peel strength and heat resistance; and the coating structure influences texture clarity, surface fineness, and chemical resistance. To perform reliably in heating, hot pressing, casting, embossing, and lamination, the material must meet several technical requirements:

- High thermal resistance: Maintain stability at 150–220°C or above without powdering, shrinking, or curling.

- Controlled release force: Enable smooth detachment from adhesives, resins, or PU/PVC compounds.

- Precision texture replication: Essential for matte, gemstone, or embossed patterns in gemstone matte high temperature release paper.

- Chemical inertness: Resist solvent-rich processes in synthetic leather and electronic applications.

- Dimensional stability: Prevent deformation and ensure product flatness during high-temperature cycles.

These characteristics enable broad application across:

- Synthetic leather casting, embossing, and surface shaping

- High-temperature adhesive tapes and protective films

- Thermosetting resin lamination

- Copper-clad laminate production

- Functional coatings and transfer processes

Manufacturing Technology Essentials and Process Control

Producing high temperature release paper involves precise coordination of raw materials, coating formulas, process parameters, curing systems, and quality inspection. This makes the field strongly dependent on equipment capability and R&D innovation. Anhui Honghuan New Material Technology Co., Ltd., a specialized enterprise integrating R&D, production, and sales, has established a systematic production framework supporting high-end release paper manufacturing.

Core Manufacturing Stages (Process Overview Table)

| Stage | Objective | Technical Focus |

|---|---|---|

| Base paper selection | Ensure mechanical strength & stability | High-density, high-smoothness industrial base paper |

| Release coating | Control peel force & heat resistance | High-temperature silicone or specialized resin systems |

| Precision coating | Achieve uniform thickness & consistency | Multi-head coating + inline inspection |

| Thermal curing | Build stable release network | High-temperature & gradient curing systems |

| Post-treatment | Refine surface texture | Matte, gemstone, or custom EMB textures |

Honghuan’s advanced detection equipment—including pilot coater systems and analytical instruments—enables accurate monitoring of peel force, thermal durability, and surface energy. Its technical team, experienced in leather release paper and specialty coatings, supports the development of customized gloss levels, EMB patterns, and special textures.

Performance Advantages and Key Requirements Across Applications

Synthetic Leather Manufacturing

High temperature release paper serves as a structural and aesthetic carrier for PU/PVC leather. Gemstone matte high temperature release paper provides stable matte effects, fine surface feel, and clear texture replication, significantly enhancing the consistency and appearance of synthetic leather.

Electronics and Adhesive Materials

In protective films, high-temperature tapes, and flexible circuits, release paper must maintain peel force stability during thermal cycles above 150°C. Chemical inertness is critical to prevent interaction with high-tack adhesives.

Thermosetting Resin Lamination

In composite panels and heat-cured laminates, high temperature release paper prevents resin adhesion, improves surface smoothness, and increases production efficiency.

Value Evolution in the New Materials Industry

As material systems advance, high temperature release paper is evolving toward higher performance and specialization. Key directions include:

- Higher thermal thresholds exceeding 220°C.

- High-precision texture reproduction, including micro-textures and deep matte surfaces.

- Low-VOC and eco-friendly release systems.

- Enhanced dimensional stability for electronics and precision laminations.

- Batch-to-batch consistency, especially in high-volume, high-precision manufacturing.

Enterprise Capabilities That Strengthen Product Reliability

Industry-leading manufacturers establish quality advantages through detection, efficiency, production capacity, and technical customization. Highlights include:

Detection Capability

Honghuan employs advanced testing equipment—pilot coating machines and analytical systems—to maintain reliable, stable product quality.

Process Efficiency & Flexible Scheduling

With tight cycle-time control from design to final production, the company supports urgent production needs without compromising quality.

Automated Production Capability

Automated and semi-automated lines enhance consistency and enable high annual output.

Quality Assurance System

A professional team of R&D specialists, production engineers, and sales experts ensures stability across every batch.

Customization Services

Tailored gloss levels, EMB designs, and OEM/ODM development provide precise solutions for diverse customer requirements.

Flexible Size Options & Low MOQ

Widths ranging from 1,600 mm to 2,350 mm and MOQs as low as 2,000 meters per roll support both large-scale and small-batch clients.

Future Development Trends

The evolution of high temperature release paper is expected to follow several predictable trends:

- Advanced surface engineering, including functional textures and micro-structured surfaces

- Eco-friendly coating technologies with reduced solvent usage

- Multi-functional release coatings integrating gloss control, anti-slip, or light-diffusion functions

- Lightweight yet high-strength base papers

- Smart manufacturing with full-process monitoring, AI-assisted inspection, and digital traceability

Conclusion

High temperature release paper plays a critical role in defining the quality, stability, and performance of synthetic leather, electronic materials, and thermosetting lamination processes. As specialized categories such as gemstone matte high temperature release paper rise in prominence, the industry continues to move toward higher temperature resistance, higher precision, and more sustainable material systems. With its integrated R&D, production, and sales capability, Anhui Honghuan New Material Technology Co., Ltd. is contributing to this evolution through technological innovation, strict quality control, flexible production, and professional customization—supporting downstream industries in achieving higher performance and more efficient manufacturing.

Copyright © Anhui Honghuan New Material Technology Co., Ltd. Rights Reserved.

Wholesale H318 Gemstone Matte High Temperature Release Paper Suppliers

English

English 中文简体

中文简体