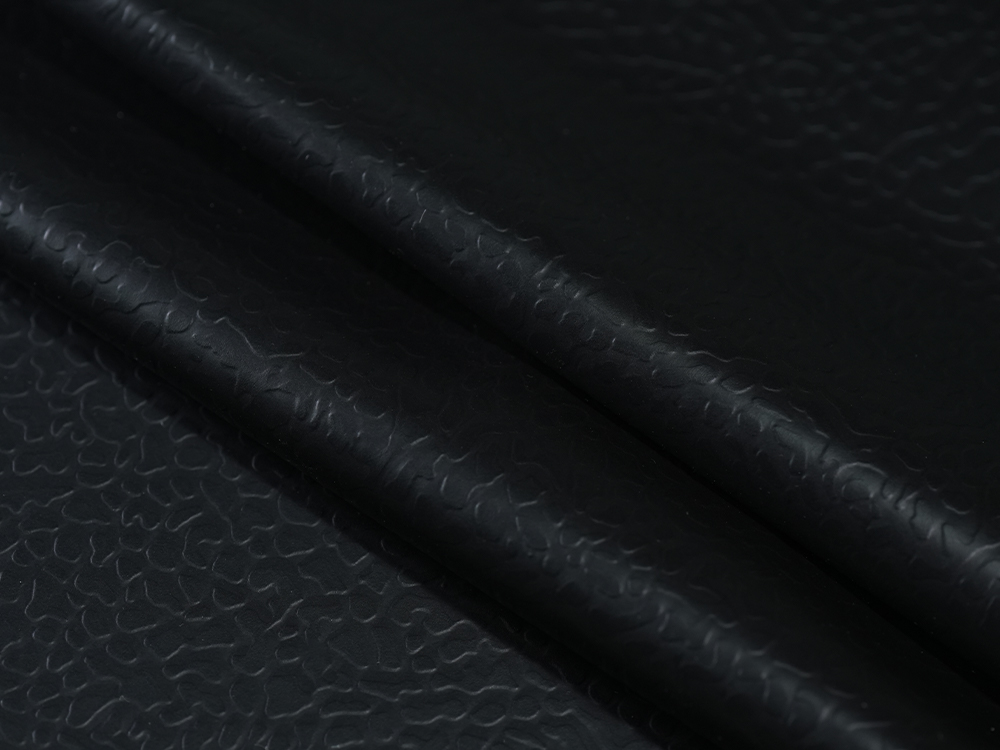

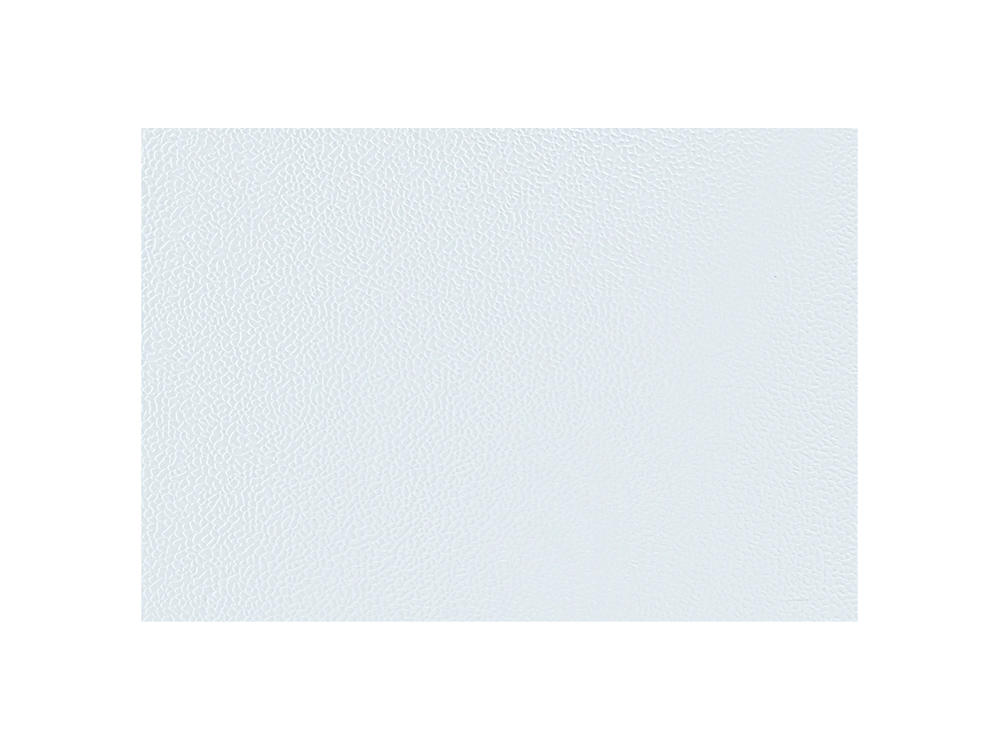

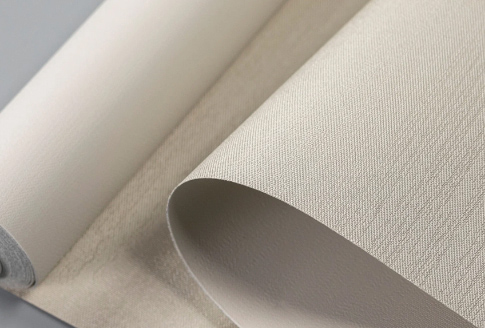

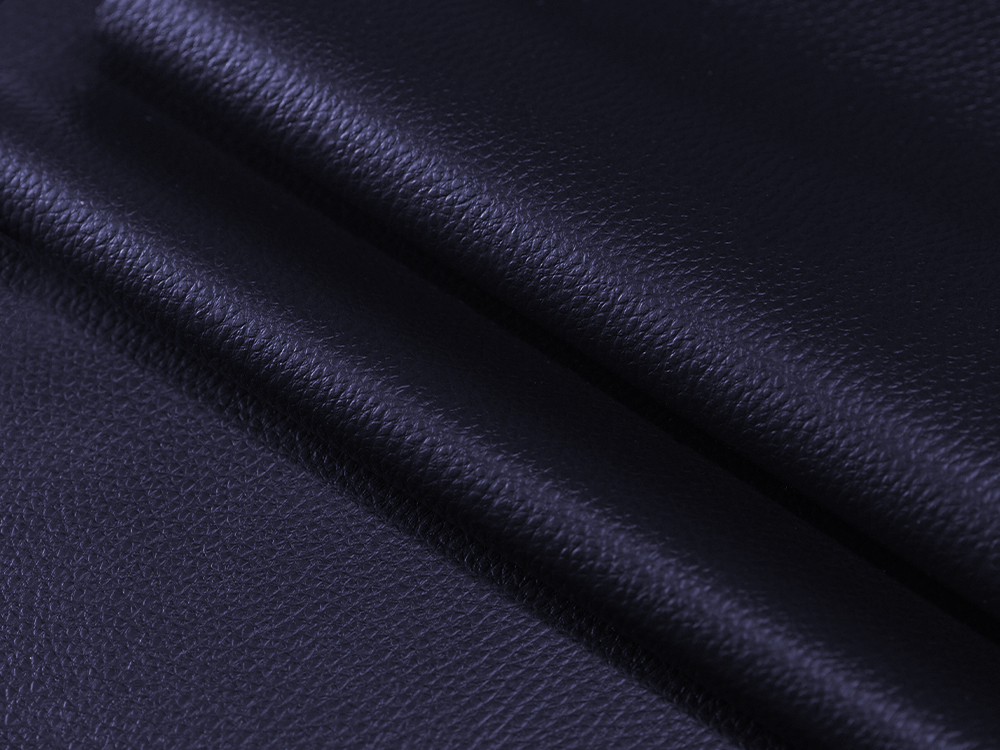

Honghuan high-temperature release paper is a kind of anti-adhesive paper specially designed for high-end artificial leather production. The leather surface produced with this release paper can present a unique gemstone texture, moderate glossiness, and semi-bright effect. Made of high-quality release paper and a layer of special silicon-based coating, the paper has excellent heat resistance and durability, and can maintain stable performance in high high-temperature environments. Its release force is adjustable, which is suitable for various PVC leather production needs. At the same time, it has good reusability and is widely used in automotive interior, floor leather, sofa leather, and luggage leather.

Submit feedback

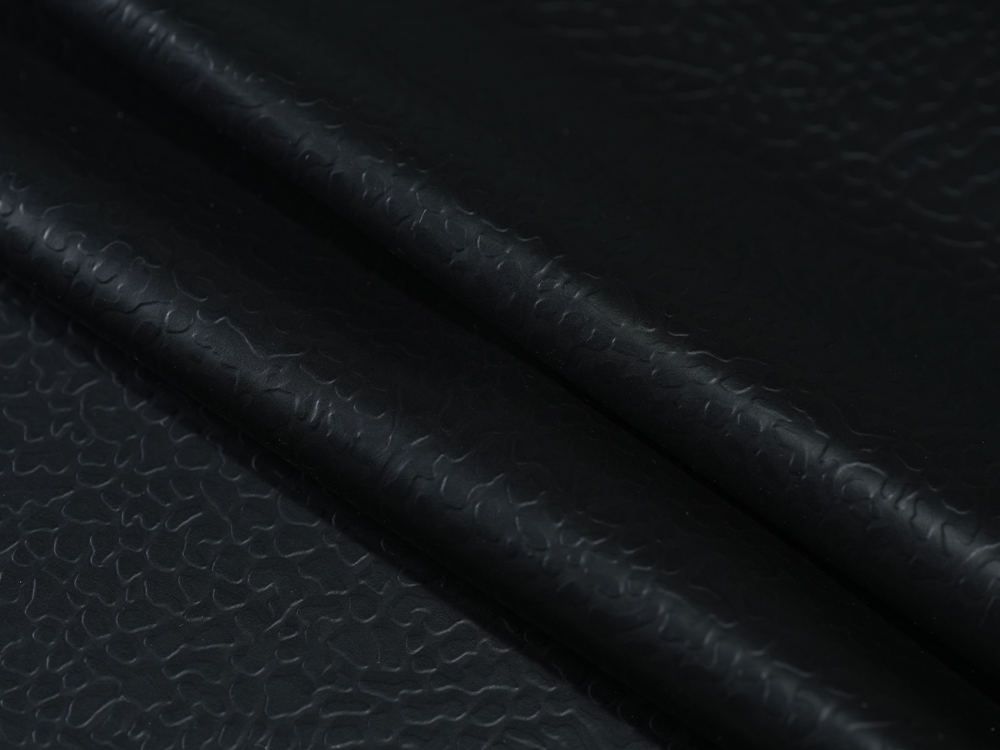

H358 Gemstone Semi-bright High Temperature Release Paper

| Item | Details |

|---|---|

| Paper Specifications | Width is customizable from 1500 mm to 2350 mm to meet diverse customer customization needs. |

| High-Temperature Stability | Maintains stable flatness, tension, folding resistance, and tear strength in a 220℃ oven, ensuring high-quality PVC leather production. |

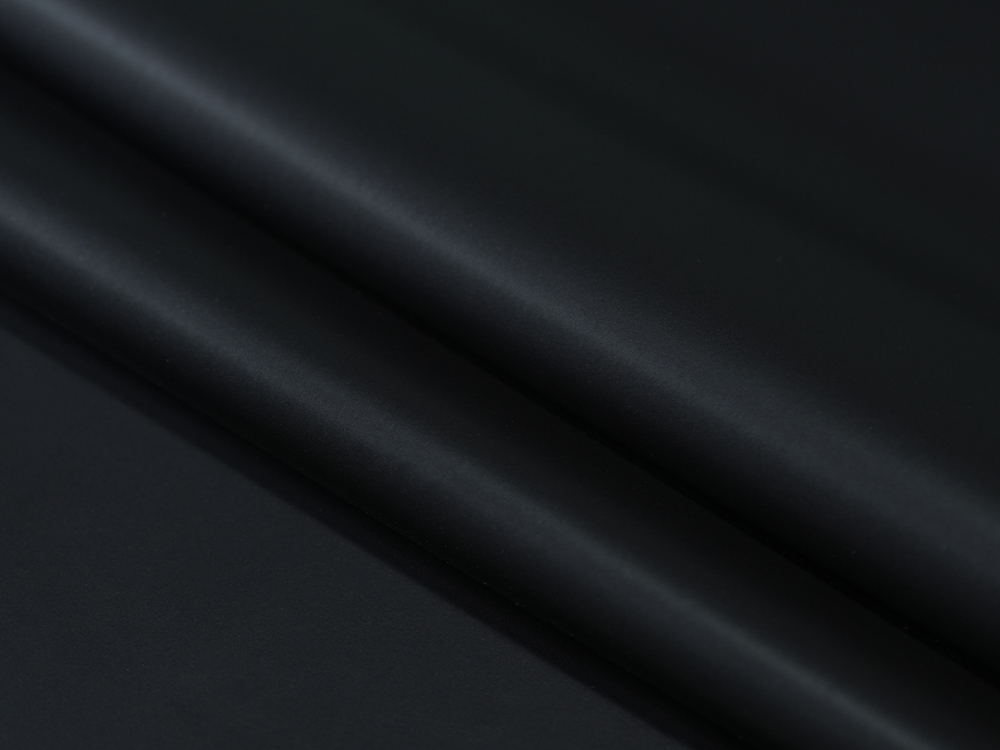

| Surface Treatment | - Semi-bright glossy gemstone effect. - Customizable gloss and smoothness options to meet specific visual requirements. |

| Release Force & Cycles | - Adjustable to light or heavy release force for different PVC leather types. - Reusable 8–15 cycles in PVC production. |

| Durability & Feedback | Excellent durability and reusability, with positive user feedback; ideal for semi-PU and PVC leather production. |

| Gloss Performance (75° Angle) | Glossiness of 40–50, ensuring visual appeal and consistency in surface finish. |

Application fields: Honghuan's high temperature resistant release paper is widely used in many fields such as automotive interior leather, floor leather, sofa leather, and luggage leather due to its excellent performance, especially suitable for the production of high-end artificial leather products. Its flexible customized specifications and stable high temperature performance make it an indispensable green production material in the synthetic leather industry, showing high flexibility and practicality.

Industry Knowledge Extension

What essential roles does high temperature release paper play in modern functional material processing?

High temperature release paper is a foundational material widely used in synthetic leather production, functional film manufacturing, adhesive systems, embossing transfer, and other thermo-processing fields. Its core value lies in providing a stable, controllable, and repeatable interface separation and texture transfer function under high-temperature, high-pressure, and chemically active environments.

Industry Background and Material Positioning

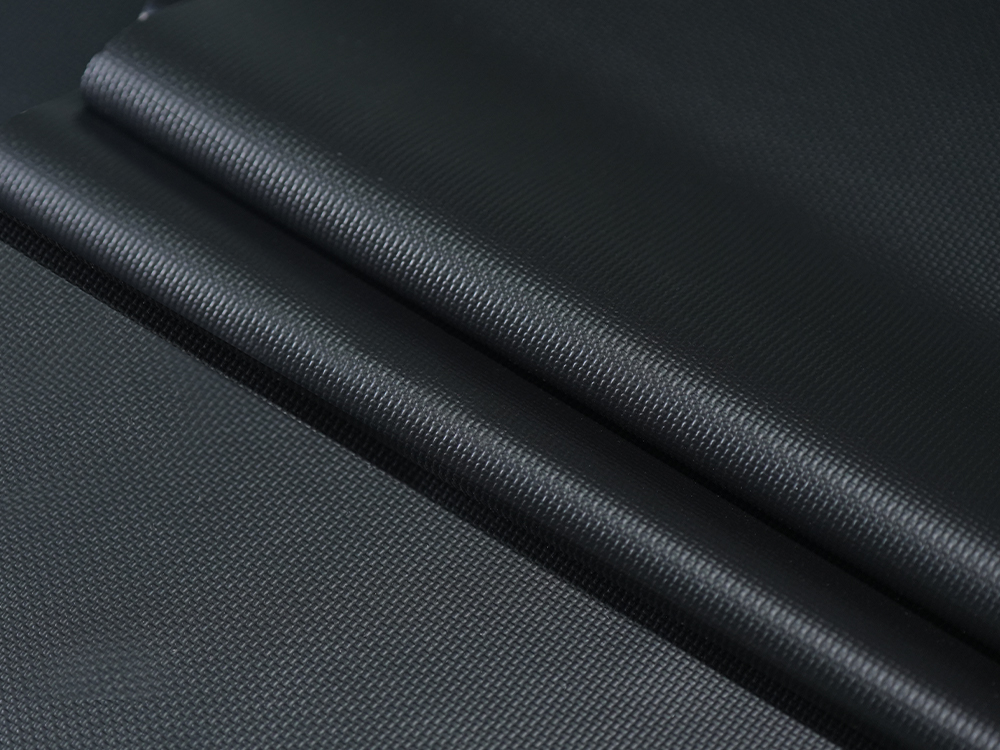

High temperature release paper is a paper-based functional material formed by coating silicone, fluorine-based, or special polymer release layers onto a high-stability base paper. The surface-energy-controlled coating enables consistent release performance and precise texture transfer during high-temperature embossing, lamination, or calendering processes.

Its key characteristics include:

- Excellent thermal resistance: stable structural performance at 180–260°C or higher

- Controlled release force: adjustable to match PU, PVC, TPU, and other resin systems

- High-fidelity texture transfer: suitable for bright, matte, semi-bright, gemstone, and leather-grain patterns

- Dimensional stability: maintains flatness and mechanical strength under thermal stress

Products such as gemstone semi-bright high temperature release paper are widely applied in footwear leather, decorative synthetic leather, and high-end embossed materials.

Structural Composition and Performance Logic

High temperature release paper typically consists of three layers: the paper base, the coating layer, and the functional surface modification layer. Its structural logic can be summarized as follows:

| Layer | Primary Function | Key Performance Indicators |

|---|---|---|

| Base Paper | Mechanical support, dimensional stability, thermal resistance | Grammage, tensile strength, heat resistance, flatness |

| Release Coating | Release function, surface-energy control | Release force, coating uniformity, thermal stability |

| Functional Finishing Layer | Texture clarity, scratch resistance, solvent resistance | Texture fidelity, anti-stain performance, surface hardness |

For gemstone-pattern semi-bright products, the coating system often incorporates composite resin structures to enhance the crystal-like reflective effect of the micro-texture.

Manufacturing Process and Key Technical Control Points

Producing high temperature release paper involves base-paper treatment, precision coating, curing, surface finishing, and texture patterning. Key technical points include:

-

Base-Paper Strengthening

Thermal-resistant impregnations and sizing treatments ensure structural integrity at high temperatures (≥240°C). -

High-Precision Coating

Techniques such as micro-gravure and precision doctor-blade coating achieve ±0.2 g/m² consistency, ensuring stable release force. -

Crosslinking and Curing

Thermal or UV curing forms highly stable crosslinked networks, enhancing heat tolerance and chemical stability. -

Texture Mold Technology

High-fidelity molds enable accurate reproduction of gemstone, leather, and micro-embossed textures, with transfer rates often exceeding 95%.

Anhui Honghuan New Material Technology Co., Ltd., a specialized enterprise integrating R&D, production, and sales, excels in precision coating technology, texture-mold development, and automated production. Honghuan manufactures high temperature release paper, PE-coated paper, and other specialty packaging materials, particularly for the synthetic-leather industry, and provides rapid and accurate technical support.

Application Mechanisms in the Synthetic Leather Industry

In PU wet-process, dry-process, transfer-coating, and film-lamination technologies, high temperature release paper serves several essential functions:

-

Interface Separation and Clean Release

Allows synthetic leather coatings to detach cleanly after curing. -

Texture Transfer and Surface Control

The pattern on the release paper determines the final surface appearance—semi-bright gemstone, matte, glossy, or leather grain. -

Influence on Resin Flow and Hand-Feel

Surface energy and micro-topography influence coating smoothness, gloss, and tactile properties. -

Enhancement of Production Efficiency

Stable release force and dimensional precision reduce defects such as wrinkles, surface distortion, or unsteady embossing.

Specialized products like gemstone semi-bright high temperature release paper offer balanced gloss, depth, and crystalline texture, making them ideal for premium footwear leather, bags, automotive interiors, and decorative synthetic material applications.

Industry Requirements and Customization Trends

As aesthetic and functional requirements increase, downstream customers demand more refined customization. Key trends include:

Gloss and Texture Precision

Semi-bright gemstone products require a delicate balance between crystal reflection and soft visual brightness.

Environmental Upgrades

Water-based coating systems, recyclable base paper, and low-VOC processing are becoming standard expectations.

Flexible Specifications and Small-Batch Supply

Anhui Honghuan New Material Technology Co., Ltd. offers widths from 1,600–2,350 mm and a low minimum order quantity of 2,000 meters per roll, enabling flexible procurement for manufacturers of varying scales.

OEM / ODM Development

Honghuan provides customized gloss levels, EMB designs, release-force adjustment, and other tailored solutions to support brand-specific texture development.

Quality Stability and Supply-Chain Support

High-temperature release paper is used in continuous, high-precision production lines, making batch-to-batch consistency essential. Key stability indicators include:

- Uniform release force and thermal behavior

- Consistent texture depth and gloss across orders

- Excellent roll smoothness and tension stability

Honghuan employs an experienced team of R&D specialists, production engineers, and quality-assurance professionals to ensure reliability and high stability for every batch. Its logistics capabilities further ensure safe and timely delivery across domestic and international markets.

Conclusion

High temperature release paper is a critical material that directly affects the texture quality, appearance uniformity, and production efficiency of synthetic leather and other functional materials. From advanced patterns such as gemstone semi-bright high temperature release paper to highly customized performance requirements, the industry continues to move toward high-precision, environmentally friendly, and functionally integrated development.

Copyright © Anhui Honghuan New Material Technology Co., Ltd. Rights Reserved.

Wholesale H358 Gemstone Semi-bright High Temperature Release Paper Suppliers

English

English 中文简体

中文简体