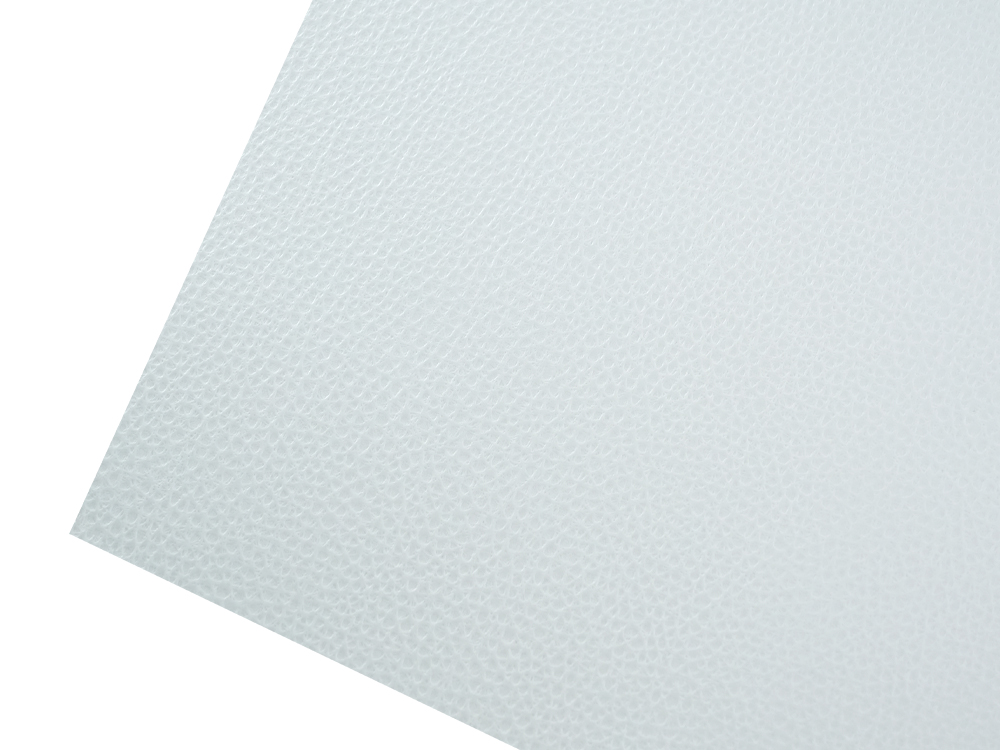

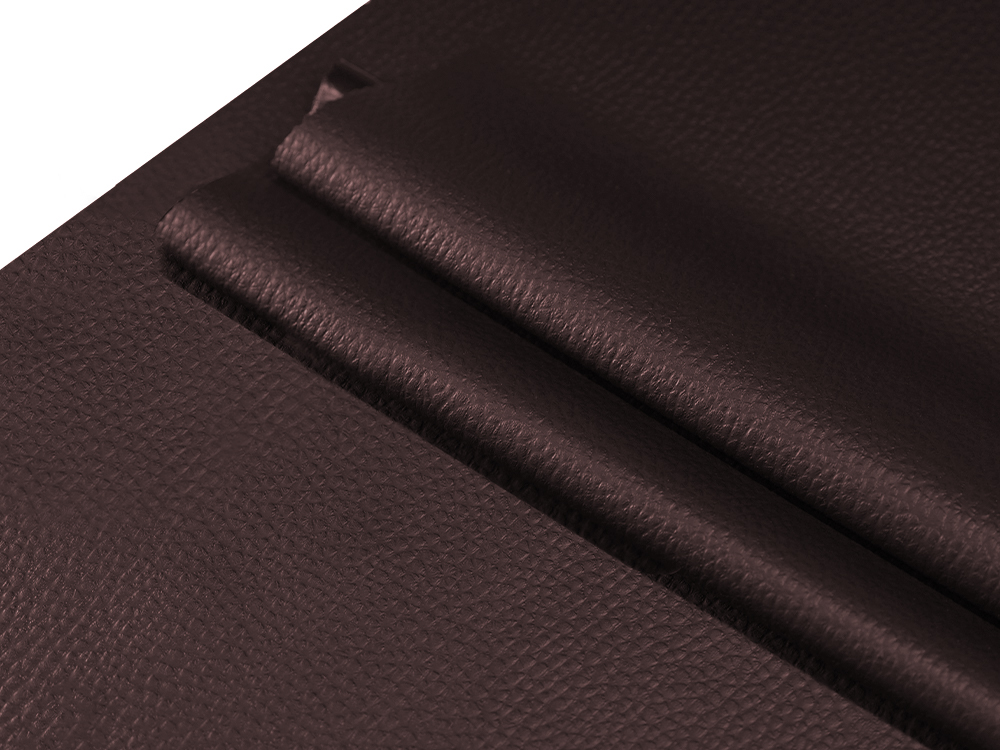

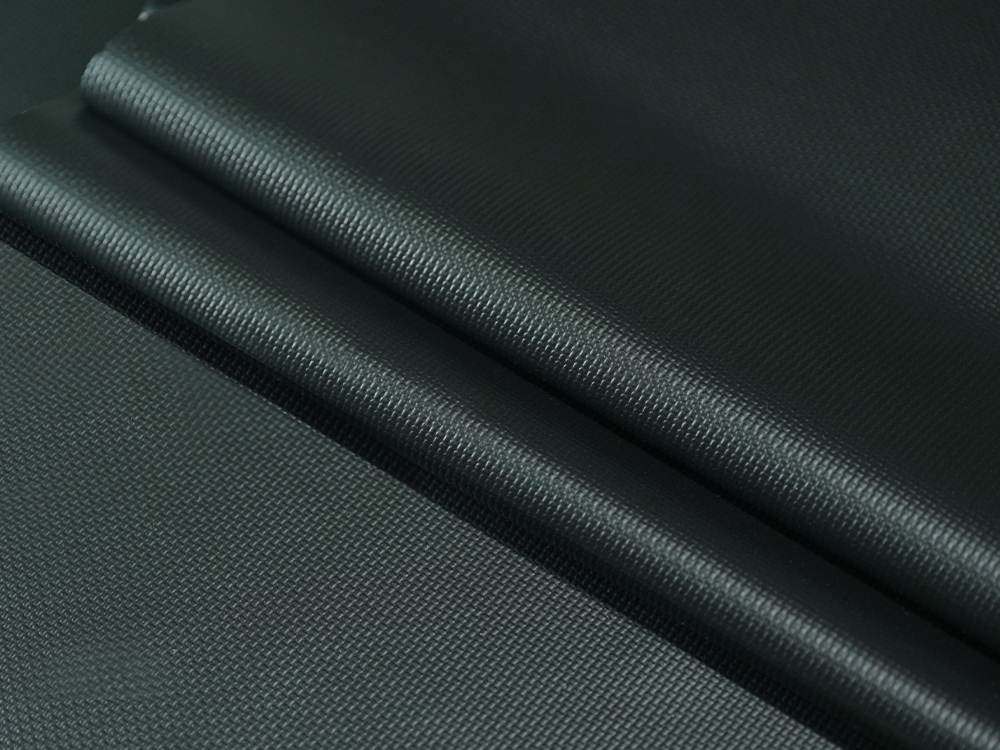

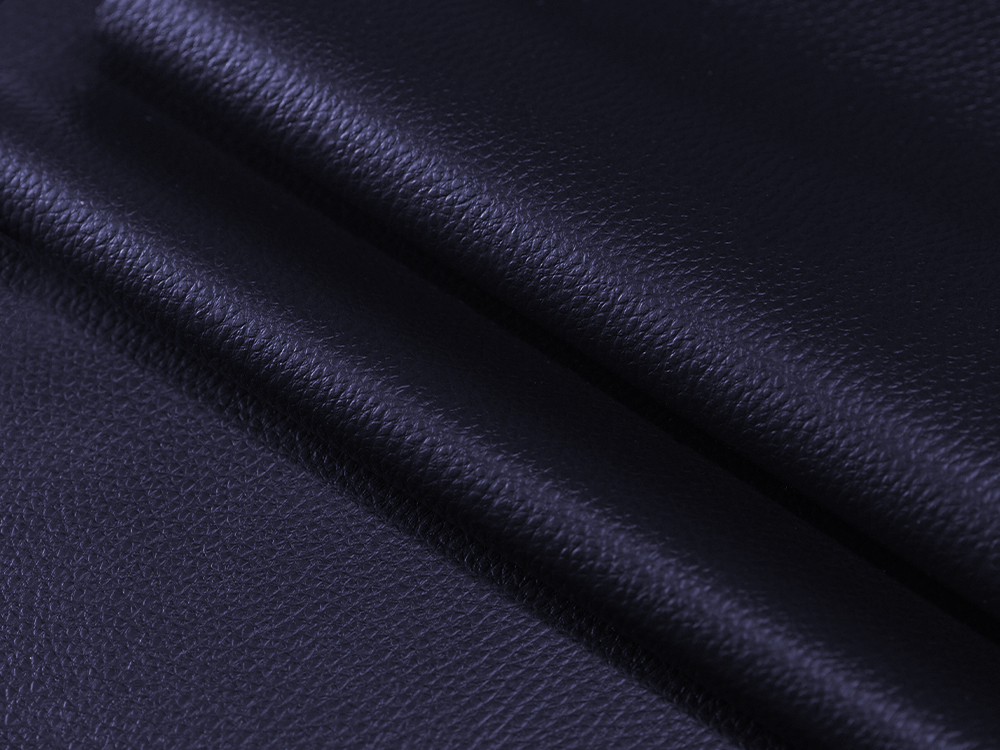

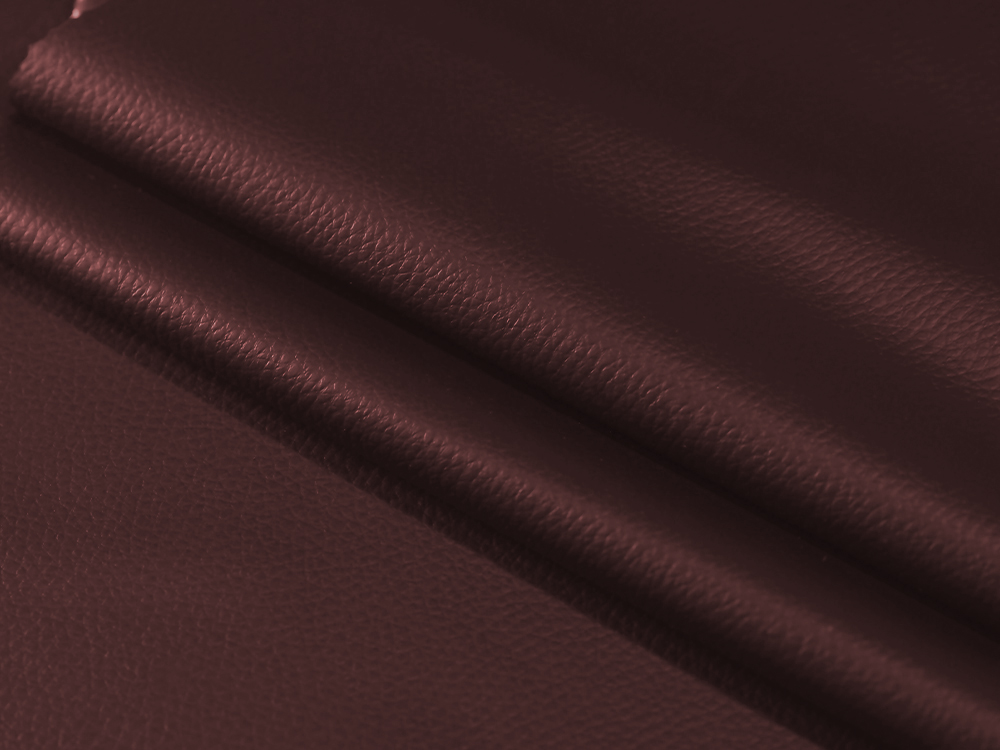

Honghuan high-temperature release paper is a kind of anti-adhesive paper designed for a super matte effect. It is made of high-quality release paper and special coating technology, with excellent flatness and durability. The leather surface produced with this release paper can form a unique litchi texture with extremely low gloss, which meets the requirements of super matte. At the same time, this product has excellent high-temperature resistance and can still maintain stable performance in an environment of 220℃, which is suitable for PVC and semi-PU artificial leather production.

Submit feedback

H508 Large Lychee Pattern Super Matt High Temperature Release Paper

| Item | Details |

|---|---|

| Paper Specifications | Customizable width from 1500 mm to 2350 mm, adapting to diverse customer production needs. |

| High-Temperature Performance | Maintains good flatness, tension, folding resistance, and tear strength in a 220℃ oven, ensuring high-quality PVC leather production. |

| Surface Treatment | - Lychee pattern design for unique visual effects. - Ultra-matte finish with glossiness of only 5–10 (75° angle). |

| Release Force Adjustment | Adjustable to light release or heavy release to suit different PVC leather production requirements. |

| Durability & Reusability | - Semi-PU production: Reusable up to 50–60 times. - PVC production: Reusable 8–15 cycles. - Exceptional reusability performance. |

| Gloss Performance (75° Angle) | Glossiness of 5–10, ensuring a consistent ultra-matte effect. |

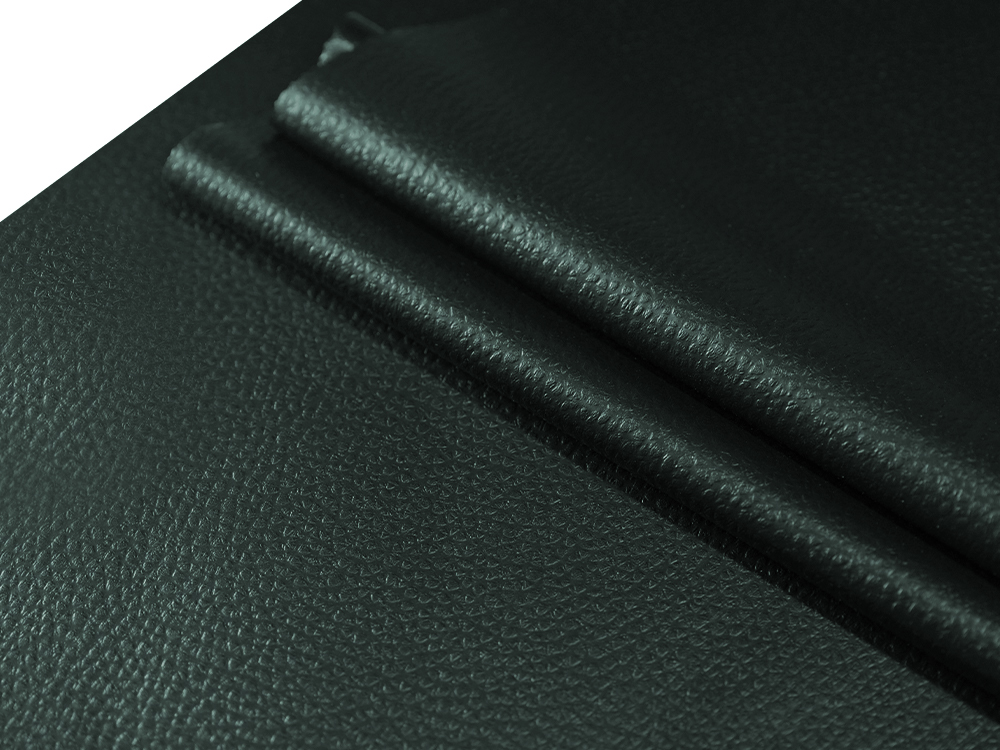

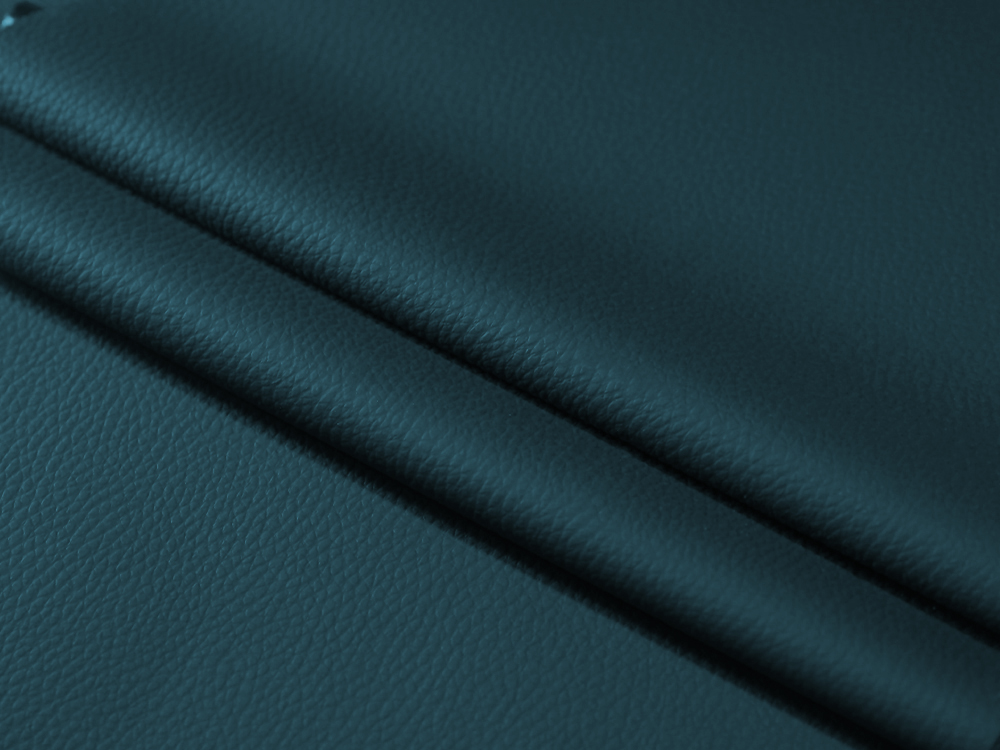

Application fields: Honghuan's high temperature resistant release paper is widely used in automotive interior leather, floor leather, sofa leather and luggage leather due to its excellent performance, and is especially suitable for the production of artificial leather products that require super matte effect. Its unique lychee texture and low gloss design make it highly flexible and competitive in the high-end market.

Industry Knowledge Extension

Why Is High Temperature Release Paper Essential for High-Performance PVC and PU Leather?

High temperature release paper is a critical branch of functional paper-based materials, widely applied in synthetic leather production, adhesive systems, composite films, and premium packaging. Its core value lies in providing controlled release properties, thermal stability, and surface-transfer functionality—key elements for achieving high-quality surface finishes and efficient manufacturing. Among these materials, super matt high temperature release paper represents a high-end category that is becoming an important driver in the upgrading of the synthetic leather industry.

Industry Positioning and Functional Mechanism

High temperature release paper is a specialty material engineered through coating or surface treatments to ensure that resins, adhesives, or synthetic leather compounds do not permanently adhere during curing, calendaring, or thermal lamination processes. It also plays a key role in transferring surface texture, gloss levels, and visual effects to the final material.

Its core functions can be summarized in three dimensions:

| Function Type | Technical Description | Representative Performance |

|---|---|---|

| Release Function | Controls release force between paper and resin | Smooth, residue-free separation |

| Surface-Transfer Function | Transfers textures, gloss levels, or super-matt effects | Super matt, high gloss, leather-grain patterns |

| Thermal Stability | Maintains flatness and mechanical strength under high temperatures | Stable at 180–220°C |

Among these, super matt high temperature release paper is valued for its ultra-low gloss, high heat resistance, and highly consistent transfer properties, especially in advanced PVC and semi-PU leather production.

Material Structure and Performance Requirements

A professional high temperature release paper typically consists of a base paper, functional coating layers, and surface treatment layers. Each layer contributes to its performance in high-temperature and high-pressure environments.

Base Paper Properties

The base paper must exhibit high density, tensile strength, dimensional stability, and flatness to withstand mechanical stress, repeated thermal cycles, and surface-transfer requirements.

Coating and Surface System

The coating determines release force, texture precision, and heat resistance. It must resist thermal decomposition, discoloration, softening, or powdering at elevated temperatures. Super matt systems require a micro-structured coating that produces uniform diffuse reflection to achieve a stable matte appearance.

Thermal-Resistance Criteria

During continuous exposure to 180–220°C, the release paper must maintain:

- Flatness without curling or blistering

- Stable coating adhesion and hardness

- Dimensional stability without shrinkage

- Consistent surface-transfer functionality

These attributes are essential for long-run PVC, PU, and semi-PU synthetic leather production lines.

Classification and Distinguishing Characteristics

High temperature release paper can be categorized according to function, surface characteristics, and application scenario.

| Category | Features | Applications |

|---|---|---|

| Super Matt High Temperature Release Paper | Ultra-low gloss, stable heat resistance, high transfer accuracy | High-end PVC leather, matte synthetic leather, footwear materials |

| High-Gloss Release Paper | High gloss, dense surface, high reusability | Glossy PVC leather, shiny bag leather |

| Embossed/Texture Release Paper | Strong texture definition, uniform transfer | Furniture leather, automotive leather |

| PE-Coated Release Paper | Water-resistant, oil-resistant, thermally stable | Composite materials, adhesive systems |

Among these, super matt high temperature release paper is technically demanding due to its need for both optical and thermal precision.

Application Value and Process Adaptability

Key Role in Synthetic Leather Production

High temperature release paper delivers significant advantages in PVC and semi-PU synthetic leather manufacturing:

-

Surface Structuring: Transfers leather grain, matte finishes, and fine visual effects.

-

Product Stability: Ensures consistent gloss, texture clarity, and uniformity.

-

Cost Reduction: High reusability reduces production costs—

- 50–60 reuse cycles in semi-PU production

- 8–15 reuse cycles in PVC production

-

Process Consistency: Maintains uniform pressure and temperature profiles throughout continuous production.

Compatibility with Manufacturing Processes

The material must withstand coating, drying, lamination, and calendaring steps. Mechanical strength, folding endurance, and flatness determine process stability. For super matt grades, durability of the micro-structured surface is essential to prevent gloss deviation during repeated use.

Industry Technology Trends

With the synthetic leather sector moving toward high performance, sustainability, and precision manufacturing, high temperature release paper is evolving in several directions:

Upgraded Ultra-Matt and Functional Surface Engineering

Super matt systems will continue advancing toward:

- More stable diffuse-reflection structures

- Higher abrasion resistance

- Improved micro-texture definition

Higher Heat Resistance and Longer Service Life

Future materials will target increased durability beyond 220°C and extended reuse cycles.

Customization and Flexible Manufacturing

The market demands greater flexibility in width, gloss, texture, and surface effects, driving manufacturers toward advanced R&D capabilities.

Enterprise Strength and Industrial Capability Example

Many companies in the industry have contributed to technological advancements. Anhui Honghuan New Material Technology Co., Ltd. integrates R&D, production, and sales, focusing on the research, development, production, and sales of release paper, PE coated paper, and other specialty packaging materials.

Its technical strengths include:

-

High-Temperature Innovation: In 2019, Honghuan developed a release paper capable of withstanding 220°C for synthetic leather applications while maintaining flatness, tensile strength, folding endurance, and tear resistance.

-

High Reusability:

- 50–60 cycles in semi-PU production

- 8–15 cycles in PVC production

-

Custom Development: Customizable widths (1520–2350 mm), gloss levels, and embossing patterns.

-

Professional Technical Support: A team of experts in leather release paper offering fast and precise after-sales services.

These capabilities reflect broader industry trends toward durability, precision, and adaptable production.

Conclusion

High temperature release paper—including super matt high temperature release paper—has become indispensable in synthetic leather and functional material manufacturing. Its significance extends beyond release functionality to embody process efficiency, surface-finish quality, and industrial cost optimization.

Copyright © Anhui Honghuan New Material Technology Co., Ltd. Rights Reserved.

Wholesale H508 Large Lychee Pattern Super Matt High Temperature Release Paper Suppliers

English

English 中文简体

中文简体