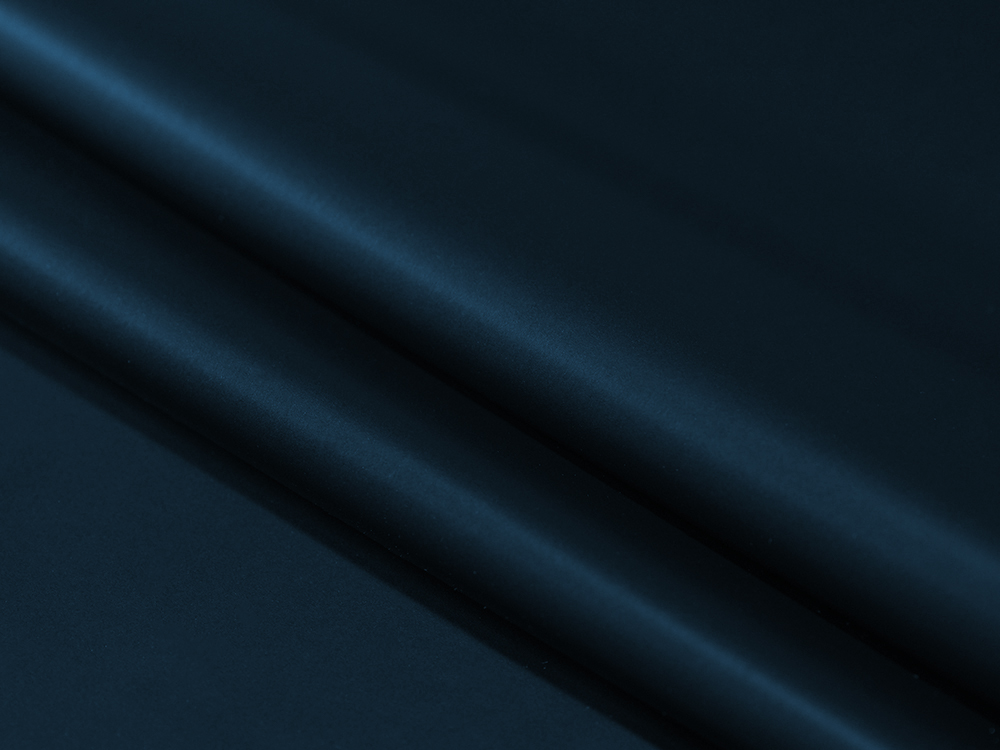

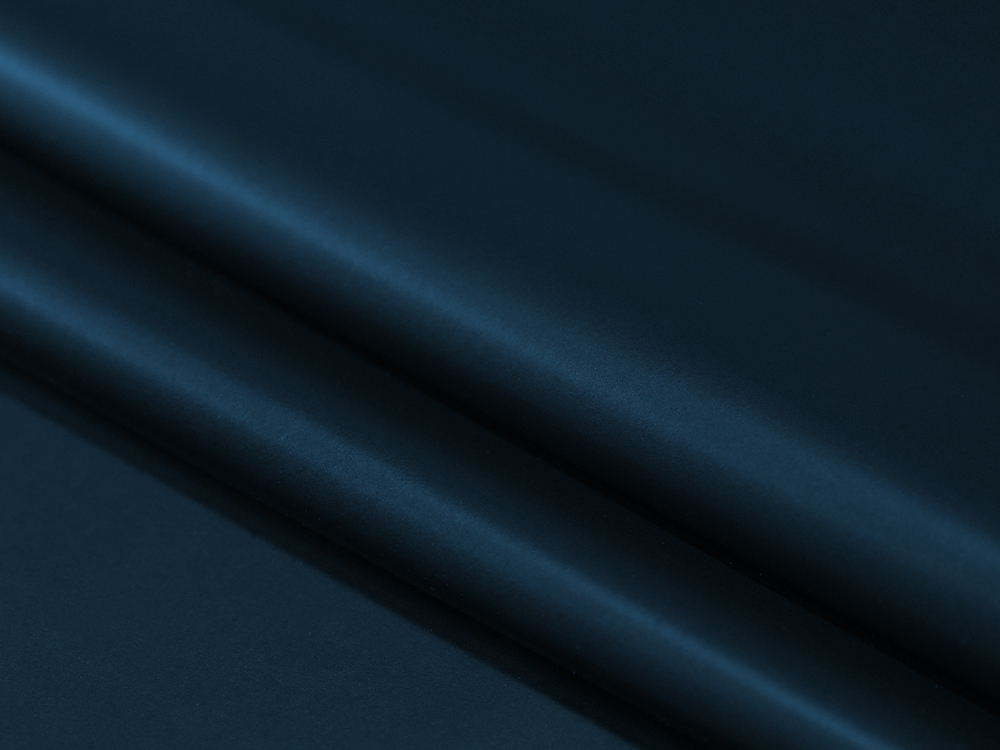

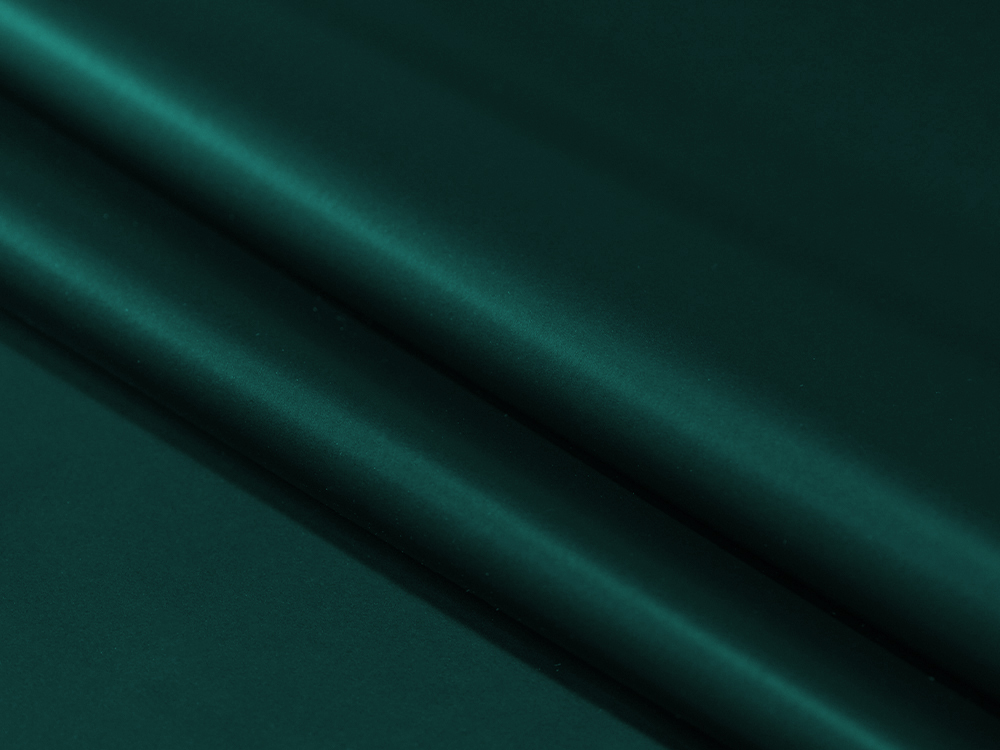

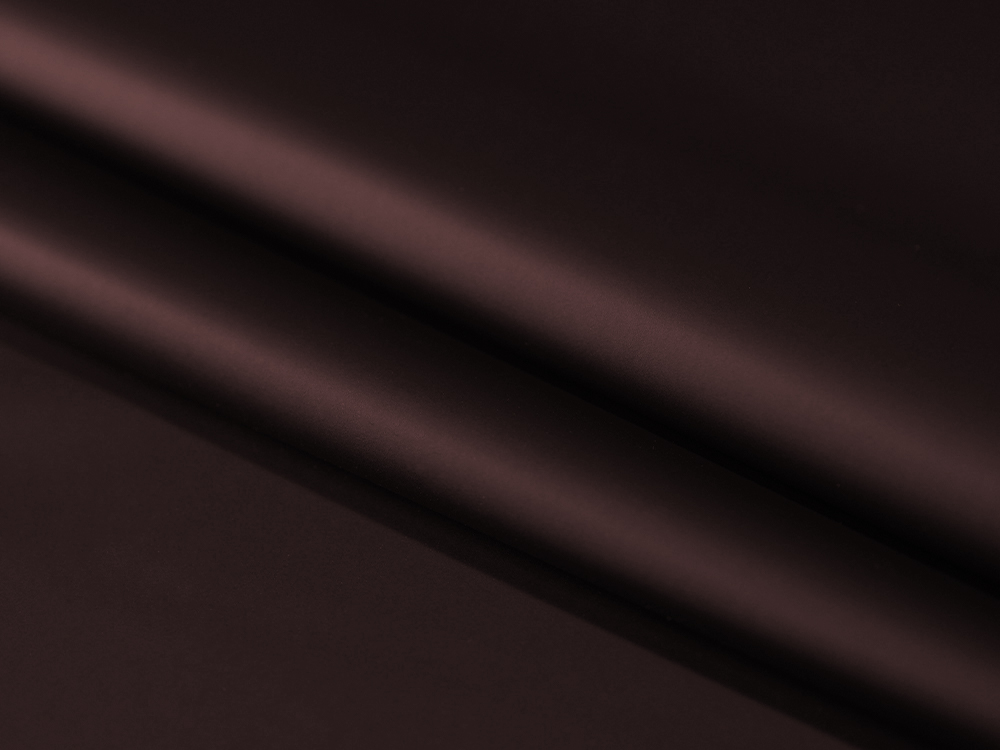

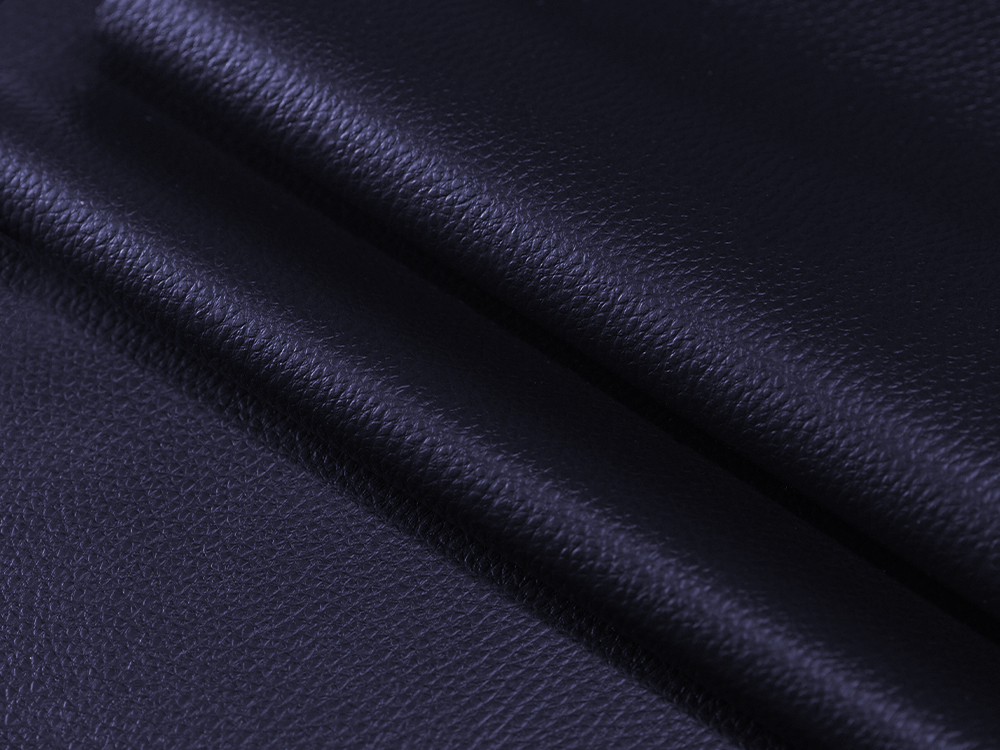

Honghuan High Temperature Release Paper is a high-quality anti-adhesive paper designed for PVC artificial leather production. It is made of high-quality release paper and special silicone-based coating, with good flatness and durability. The leather produced with this release paper can present a semi-bright gloss effect. The product performs well in high-temperature environments and is suitable for 220℃ oven operation, ensuring the stability of the paper and high-quality output during the production process. High temperature release paper supports customized specifications to meet the diverse needs of different customers.

Submit feedback

H858 Plain Semi-Bright High Temperature Release Paper

| Item | Details |

|---|---|

| Paper Specifications | Width customizable from 1500 mm to 2350 mm to suit diverse production needs. |

| High-Temperature Performance | Maintains flatness, tension, folding resistance, and tear strength in a 220℃ oven, ensuring high-quality PVC leather output. |

| Surface Treatment | Semi-bright gloss finish with a gloss level of 40–50 (measured at 75° angle) to meet visual requirements. |

| Release Force Adjustment | Adjustable to light release or heavy release to accommodate different PVC leather production processes. |

| Durability & Reusability | - Semi-PU production: Reusable up to 50–60 times. - PVC production: Reusable 8–15 times. - Widely praised for reliability by users. |

| Gloss Uniformity | Uniform surface gloss meets the 40–50 standard at a 75° angle. |

Application fields: Honghuan's high temperature resistant release paper is widely used in the production of automotive interior leather, floor leather, sofa leather, luggage leather, and other fields due to its excellent performance. Its high temperature resistance makes it the best choice for the production of PVC and semi-PU synthetic leather, while showing high flexibility and environmental protection, meeting the high standards of modern industrial production.

Industry Knowledge Extension

Why Is High Temperature Release Paper Crucial for Composite Material Production?

High temperature release paper is a type of functional paper designed to maintain stable performance under high-temperature conditions, ensuring that products do not stick during processing. It is widely used in synthetic leather manufacturing, hot-press molding, composite material processing, and other industries, making it an essential material in modern industrial production.

Definition and Key Properties of High Temperature Release Paper

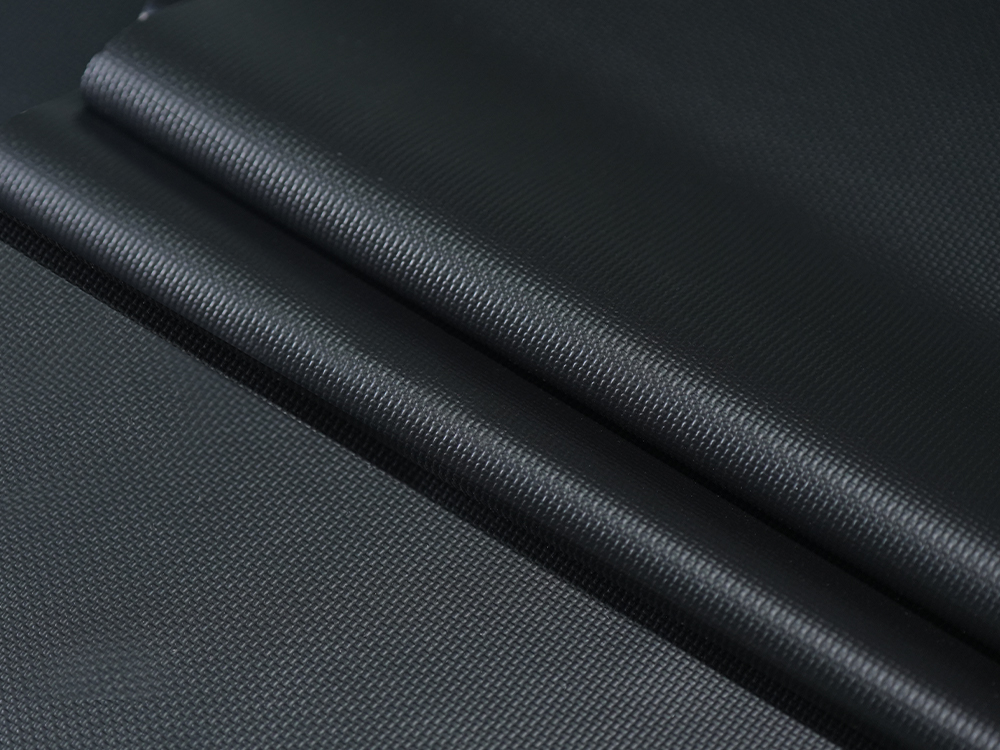

High temperature release paper refers to paper materials specially treated to retain heat resistance and anti-adhesive properties under elevated temperatures. Among its varieties, plain semi-bright high temperature release paper is the most commonly used in industrial applications. This type of paper has a semi-bright, smooth surface, uniform coating, and consistent release performance at high temperatures, while also offering excellent mechanical strength and dimensional stability.

The primary characteristics of high temperature release paper include:

- Heat Resistance: Capable of withstanding temperatures above 200°C without warping, discoloration, or decomposition, ensuring stability during hot-press or thermal lamination processes.

- Superior Release Performance: The surface coating, usually composed of high-performance silicone or other release agents, allows easy separation from materials under high heat without causing damage.

- Mechanical Strength and Toughness: The paper substrate is made from high-quality pulp with optimized fiber arrangement, ensuring it does not tear or deform under high temperature and pressure.

- Surface Uniformity: Especially in plain semi-bright high temperature release paper, the semi-bright, smooth surface ensures even pressure distribution and consistent heat conduction during hot-press molding.

Production Process and Technical Features

The production of high temperature release paper primarily involves three stages: paper substrate preparation, surface coating, and post-processing. First, the paper base is made from high-strength, low-impurity pulp, forming a uniform thickness and density through precise papermaking processes. Then, surface coating is applied, typically using high-performance silicone oil, fluorinated coatings, or composite materials to ensure excellent release performance at high temperatures. Finally, drying, curing, and cutting produce the finished high temperature release paper ready for industrial use.

Anhui Honghuan New Material Technology Co., Ltd. has developed a complete production system and stringent quality control standards for high temperature release paper. Honghuan’s technical team specializes in innovative manufacturing of release paper for synthetic leather, utilizing advanced coating technology and automated production lines to achieve high precision and stable performance. Their rapid-response technical team provides accurate after-sales support, ensuring continuous efficiency and stability during high temperature release paper applications.

Applications of High Temperature Release Paper

High temperature release paper is widely applied in various industrial sectors:

-

Synthetic Leather Manufacturing

During synthetic leather production, hot pressing or lamination at high temperatures is required. Plain semi-bright high temperature release paper prevents sticking between the leather surface and molds or press plates, ensuring smooth and defect-free surfaces. -

Composite Material Processing

In the production of hot-pressed composites, insulation boards, and automotive interior parts, high temperature release paper serves as a separating medium, preventing contamination and facilitating easy demolding. -

Packaging and Protective Materials

It can be used as a high-temperature-resistant packaging material for transporting or storing precision electronics, heat-sensitive materials, and chemical products, providing isolation, protection, and easy release. -

Other Industrial Applications

Applications also extend to heat transfer printing, rubber products, and composite films, making high temperature release paper an indispensable auxiliary material for high-temperature manufacturing.

Selection and Performance Optimization

Choosing the right high temperature release paper requires consideration of several factors:

- Heat Resistance Rating: Select paper that can withstand the specific temperature requirements of the process to prevent deformation or coating failure.

- Stable Release Performance: Prioritize papers with uniform coating and long-lasting anti-adhesion properties, such as plain semi-bright high temperature release paper, to ensure reliability over repeated use.

- Size and Thickness: Different processes require specific paper thickness and dimensions. Proper thickness ensures mechanical strength while maintaining efficient heat transfer.

- Environmental and Safety Considerations: Choose materials that meet environmental standards and minimize harmful gas emissions during high-temperature processing.

Industry Trends and Technological Innovation

With continuous industrial advancements, the high temperature release paper industry is experiencing several trends:

-

Functional Diversification

High temperature release paper is evolving to include additional properties such as anti-static, stain resistance, and chemical resistance, beyond basic heat resistance and release functions. -

Eco-Friendly Materials

Environmental regulations and sustainable manufacturing practices are driving the use of recyclable or biodegradable paper substrates and coatings. -

Smart Production and Precision Control

Automated production lines and real-time quality monitoring improve efficiency and ensure consistent coating thickness and distribution, enhancing product reliability. -

Global Market Expansion

Expanding applications in synthetic materials, electronics, and other industries are driving global demand, prompting manufacturers to scale up research and export markets.

Industry Contribution

As a professional high temperature release paper manufacturer, Anhui Honghuan New Material Technology Co., Ltd. plays a leading role in the industry. The company not only provides plain semi-bright high temperature release paper but also develops high-performance coated paper, PE-coated paper, and other specialty packaging materials. By integrating R&D, production, and sales, Honghuan offers rapid, precise after-sales service, ensuring the efficient application of high temperature release paper in industrial processes.

Through continuous technological innovation and strict quality control, Honghuan maintains product performance stability while promoting overall industry advancement, enhancing competitiveness in high-end manufacturing sectors.

Conclusion

High temperature release paper is a critical foundational material for high-temperature processing and specialty material manufacturing. Its heat resistance, stable release properties, and mechanical performance directly impact production efficiency and product quality.

Copyright © Anhui Honghuan New Material Technology Co., Ltd. Rights Reserved.

Wholesale H858 Plain Semi-Bright High Temperature Release Paper Suppliers

English

English 中文简体

中文简体