In the semi-PU (polyurethane/PU and PVC hybrid) artificial leather industry, the application of release paper combines characteristics of both PU and PVC processes but requires adjustments to accommodate the unique properties of semi-PU materials. Below are its core applications and technical considerations:

1. Characteristics of Semi-PU Artificial Leather & Role of Release Paper

-

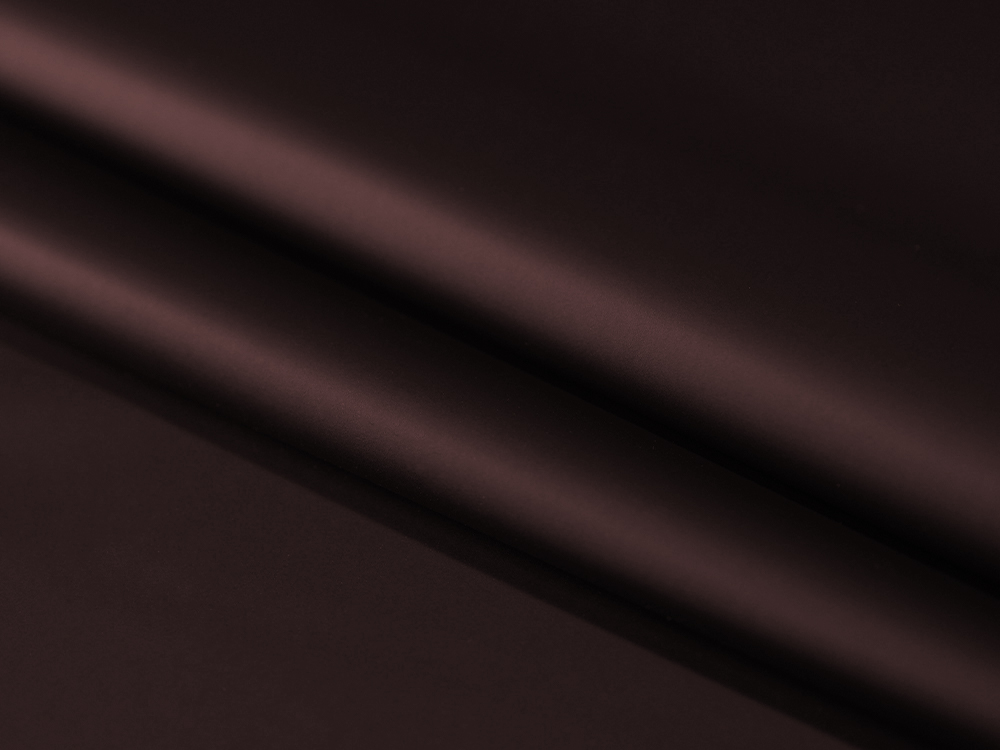

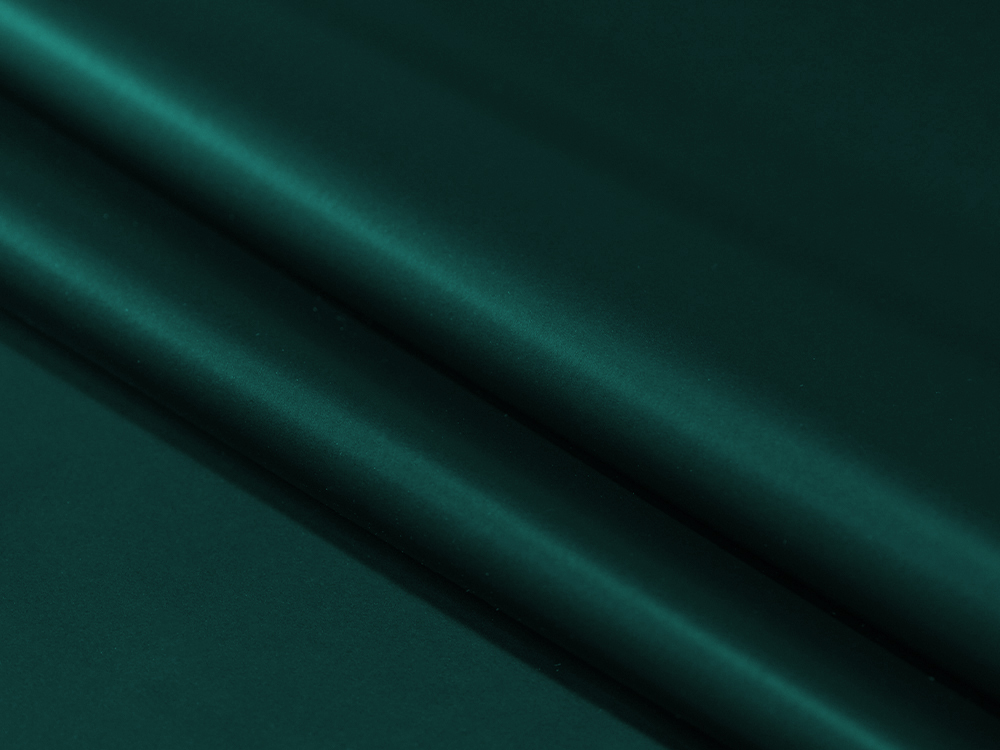

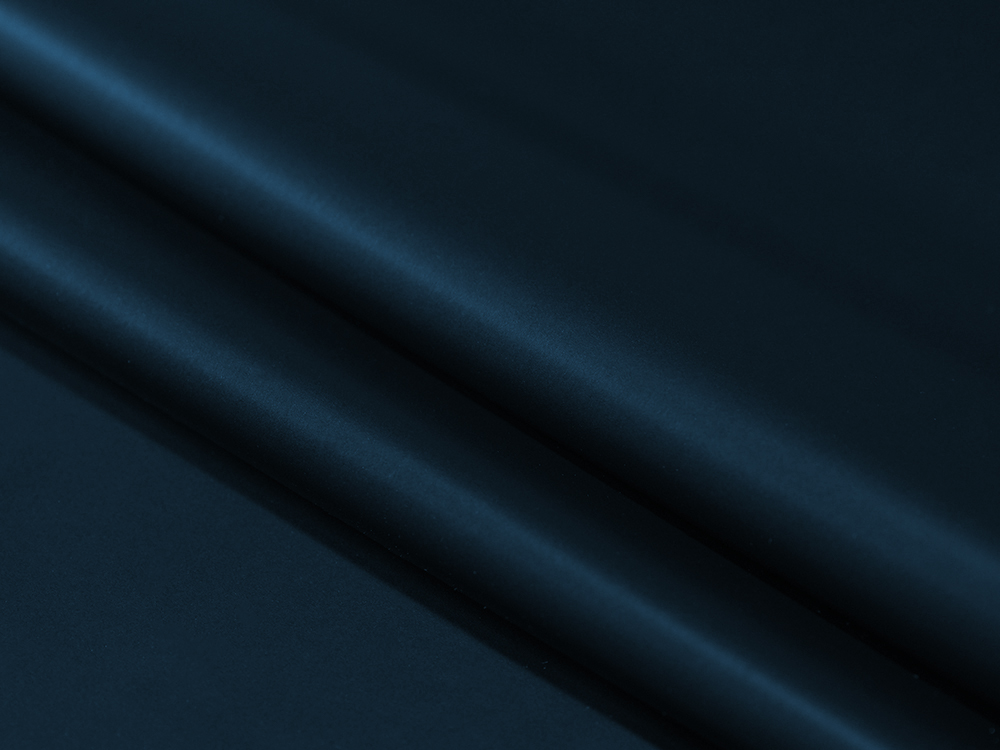

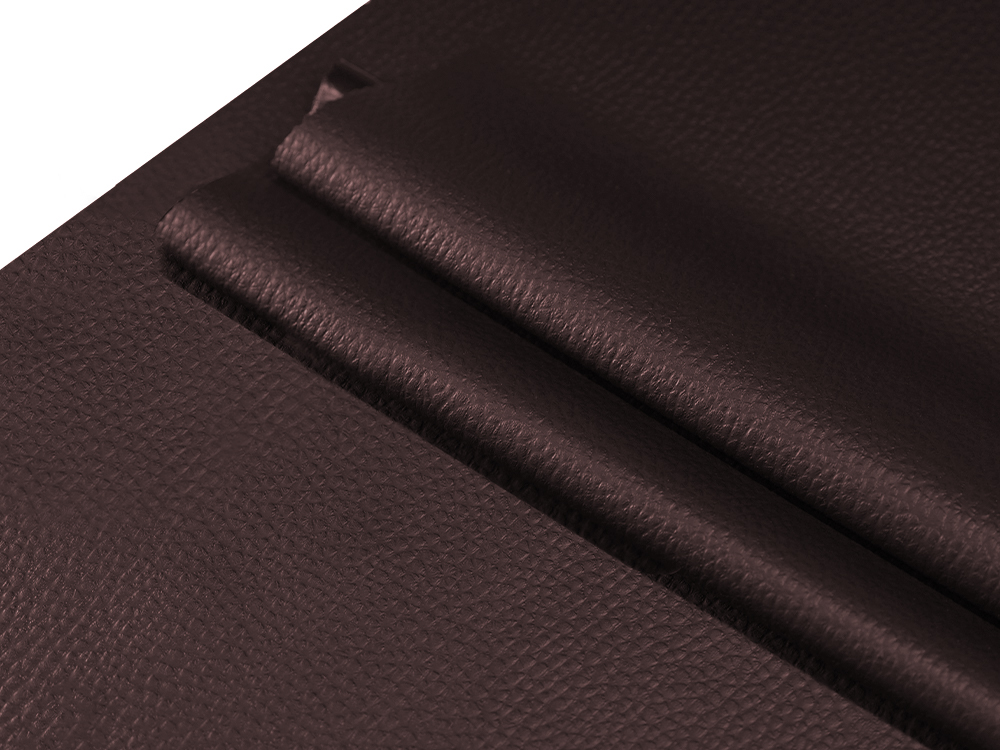

Material Properties: Semi-PU typically uses PVC as the base layer with a PU surface coating, combining PVC's cost advantages with PU's softness and wear resistance.

-

Key Functions:

-

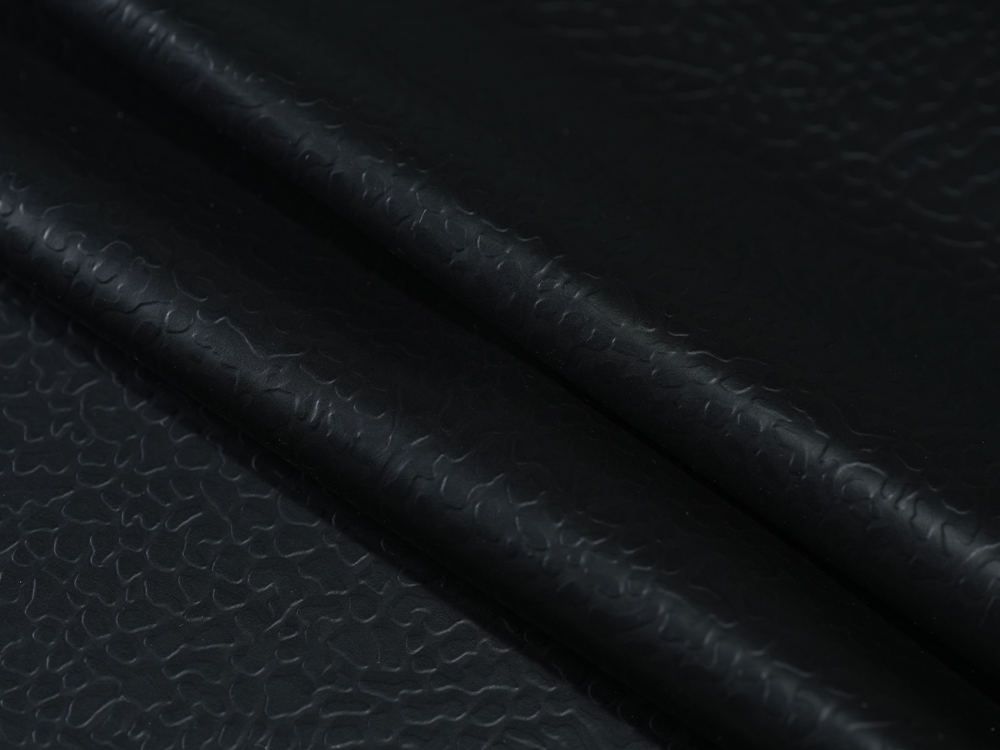

Texture Transfer: The release paper imparts high-fidelity textures (e.g., cowhide, sheepskin) onto the PU coating.

-

Dual-Layer Release: Must adapt to the differing curing temperatures and chemical properties of the PVC base and PU surface layers.

-

2. Application in Key Process Flows

-

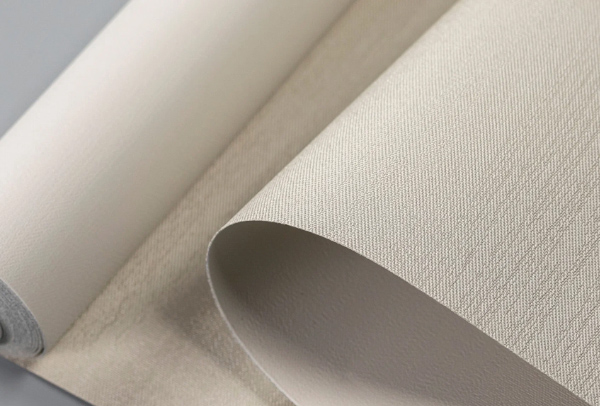

PVC Base Layer Coating: The release paper first carries the PVC paste, forming a base after drying.

-

PU Surface Layer Coating: PU resin is applied over the PVC layer, and the release paper is used for secondary embossing.

-

Staged Curing:

-

PVC layer curing temperature: 150–180°C (requires heat-resistant release paper).

-

PU layer curing temperature: 100–140°C (prevents silicone oil migration in the release paper).

-

-

Release: After cooling, the release paper is separated, preserving the PU layer's fine texture.

3. Selection Criteria for Release Paper

-

Temperature Gradient Resistance: Must withstand both PVC's high temperatures and PU's medium-to-low temperatures to prevent silicone oil failure or paper deformation.

-

Chemical Compatibility:

-

Resists penetration by PVC plasticizers (e.g., DINP).

-

Prevents dissolution of silicone coatings by PU solvents (e.g., DMF, MEK).

-

-

Texture Adaptability:

-

Coarse Textures: Used for products like sofas and luggage that emphasize three-dimensional effects.

-

Fine Textures: Used for apparel and gloves requiring a soft touch.

-

4. Industry Challenges & Solutions

-

Interlayer Adhesion Issues:

-

Solution: Use low-surface-energy release paper to minimize PU residue and ensure strong PVC/PU bonding.

-

-

Solvent Residue Risks:

-

Solution: Employ solvent-resistant silicone oils (e.g., platinum-catalyzed silicone) to prevent erosion by PU solvents.

-

-

Cost Control:

-

Solution: Adopt reusable release paper (e.g., 5–8 cycles) to offset semi-PU's higher material costs.

-

5. Future Trends

-

Eco-Friendly Release Paper: Adapt to DMF-free semi-PU processes with water-based silicone coatings.

-

Composite Texture Technology: Achieve combined PVC base textures and PU surface textures (e.g., coarse base + microporous surface) in a single molding step.

-

Smart Detection: Embed micro-markers on release paper surfaces for online monitoring of texture transfer uniformity.

Conclusion

In semi-PU artificial leather production, release paper is the critical medium for achieving "PVC cost-efficiency + PU premium quality." Its selection must precisely match the temperature, chemical, and texture requirements of the dual-material system while balancing cost and performance. As semi-PU expands into automotive interiors and high-end furniture applications, the weather resistance, reusability, and environmental standards of release paper will become key technological breakthroughs.

English

English 中文简体

中文简体