Release paper is equally critical in the PVC floor leather industry, particularly in embossing processes and surface texture design, serving as a temporary carrier to help the PVC layer form specific patterns and tactile effects. Below is a detailed analysis of the applications and key technical points of release paper in the PVC floor leather industry:

1. Roles of Release Paper in PVC Floor Leather

(1) Texture Embossing

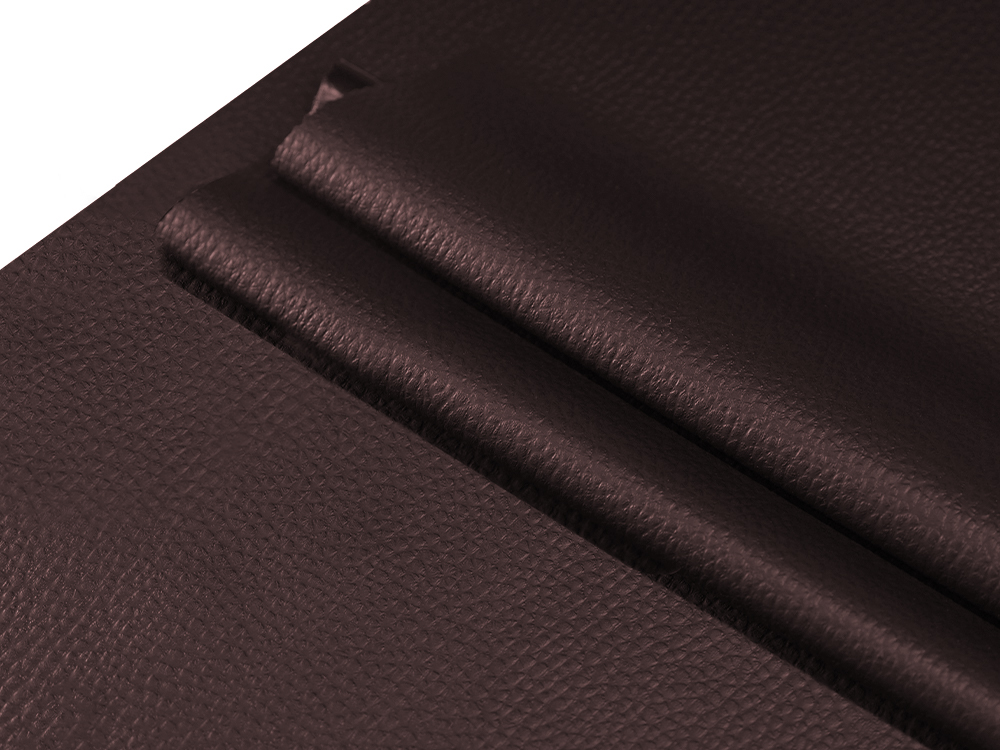

- The surface of PVC floor leather often requires decorative textures such as wood grain, stone grain, or geometric patterns. Release paper transfers these patterns to the PVC surface through hot-pressing processes.

- The silicone oil coating on release paper ensures smooth peeling after embossing, preserving the quality of the PVC surface.

(2) Demolding Function

- In PVC floor production, release paper acts as a temporary substrate to prevent the molten PVC layer from sticking to embossing rollers or molds, ensuring production efficiency.

(3) Surface Gloss Control

- The surface finish of different release papers influences the final gloss of PVC floor leather (e.g., matte, semi-matte, high-gloss).

2. Key Application Stages in PVC Floor Leather Production

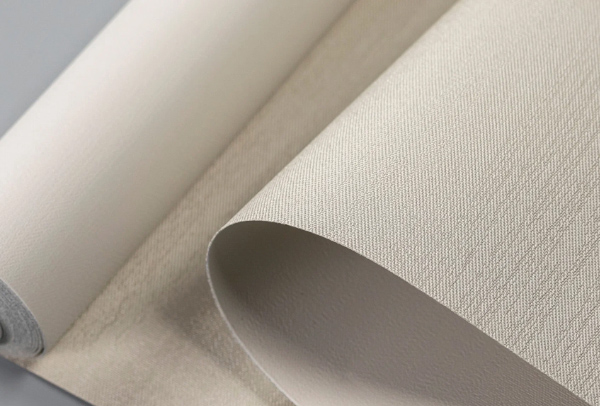

(1) Coating/Calendering Process

- A mixture of PVC paste resin, plasticizers, stabilizers, etc., is coated or calendered onto release paper to form a uniform PVC layer.

- The flatness of release paper directly affects the thickness uniformity of the PVC layer.

(2) Hot-Pressing/Embossing Process

- Under high temperature (typically 160–200°C) and pressure, the patterns on release paper are embossed onto the PVC surface.

- Common Processes:

- Dry Embossing: Release paper is hot-pressed with the PVC layer, then peeled off after cooling.

- Wet Embossing: Embossing is done before the PVC is fully cured, with release paper assisting in shaping.

(3) Cooling and Peeling

- After embossing, the PVC is cooled and shaped, and the release paper is peeled off, leaving the pattern on the PVC floor surface.

- High-quality release paper can be reused 5–15 times (depending on heat resistance and mechanical strength).

3. Common Types of Release Paper for PVC Floor Leather

| Type | Characteristics | Suitable Processes |

|---|---|---|

| Glassine Release Paper | High temperature resistance (200°C+), high strength, suitable for high-precision embossing | High-end wood/stone grain floor leather |

| CCK Release Paper | Fine surface, suitable for delicate textures (e.g., marble, fabric patterns) | Home and commercial flooring |

| PE Release Paper | Good chemical resistance, suitable for PVC formulas with high plasticizer content | Low-cost floor leather |

| Embossed Release Paper | 3D textures formed by embossing or chemical etching (e.g., relief wood grain, woven patterns) | Solid wood imitation and personalized design |

4. Industry Trends and Challenges

(1) Environmental Requirements

- Plasticizer-Free (DOP-Free) PVC: New eco-friendly plasticizers (e.g., DINCH, ESBO) demand higher chemical resistance from release paper.

- Recyclable Release Paper: Some enterprises use release paper reusable over 10 times to reduce waste.

(2) High-Fidelity Textures

- Market demands for realistic wood/stone imitations are increasing, requiring higher texture precision in release paper (e.g., high-definition digital embossing technology).

(3) Production Efficiency

- High-speed embossing lines require release paper with superior heat resistance and tensile strength to minimize downtime for paper replacement.

5. Comparison: Release Paper vs. Other Embossing Processes

| Embossing Method | Advantages | Disadvantages | Application Scenarios |

|---|---|---|---|

| Release Paper Embossing | Fine patterns, customizable, high fidelity | Higher cost, requires paper replacement | High-end PVC flooring, personalized design |

| Steel Roller Embossing | High production efficiency, suitable for mass production | Limited patterns, high replacement cost | Standardized PVC flooring (e.g., commercial) |

| Digital Inkjet Embossing | No release paper needed, quick pattern changes | High equipment cost, 耐磨性待提升 (abrasion resistance to be improved) | Small-batch customized flooring |

6. Future Development Directions

- Higher Heat Resistance: Adapt to solvent-free PVC and high-speed calendering processes.

- Degradable Release Paper: Reduce environmental impact (e.g., recyclable paper-based release paper).

- Composite Functional Release Paper: Coatings with anti-fouling or anti-static properties to enhance PVC floor performance.

Conclusion

Release paper plays a core role in achieving high-fidelity surface textures and ensuring efficient demolding in the PVC floor leather industry. As market demands for environmental protection, personalization, and realism grow, release paper technology continues to evolve. Enterprises should select appropriate release paper types based on product positioning (e.g., high-end home vs. commercial wear-resistant flooring) and optimize embossing processes to balance cost and quality.

English

English 中文简体

中文简体