Release paper is primarily used in the production of artificial leather (PU/PVC leather) for 箱包 (luggage and bags), playing a key role in endowing bag fabrics with specific textures, hand feels, and appearances. Below are the detailed applications and key technical points of release paper in the luggage and bag industry:

1. Functions of Release Paper in the Luggage and Bag Industry

(1) Texture and Appearance Design

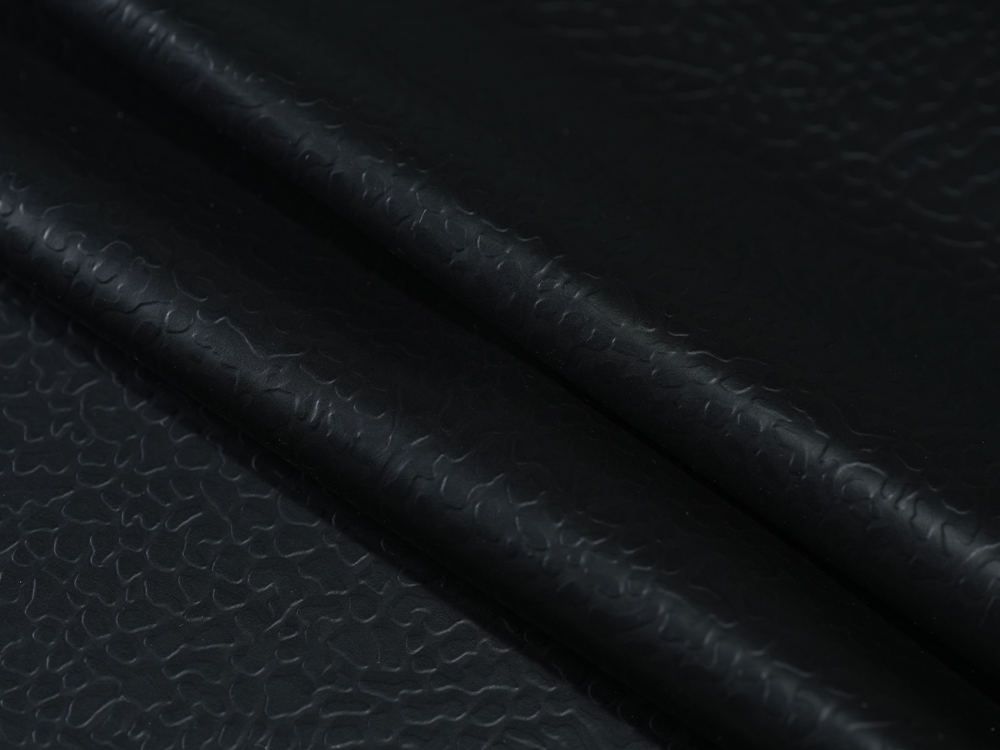

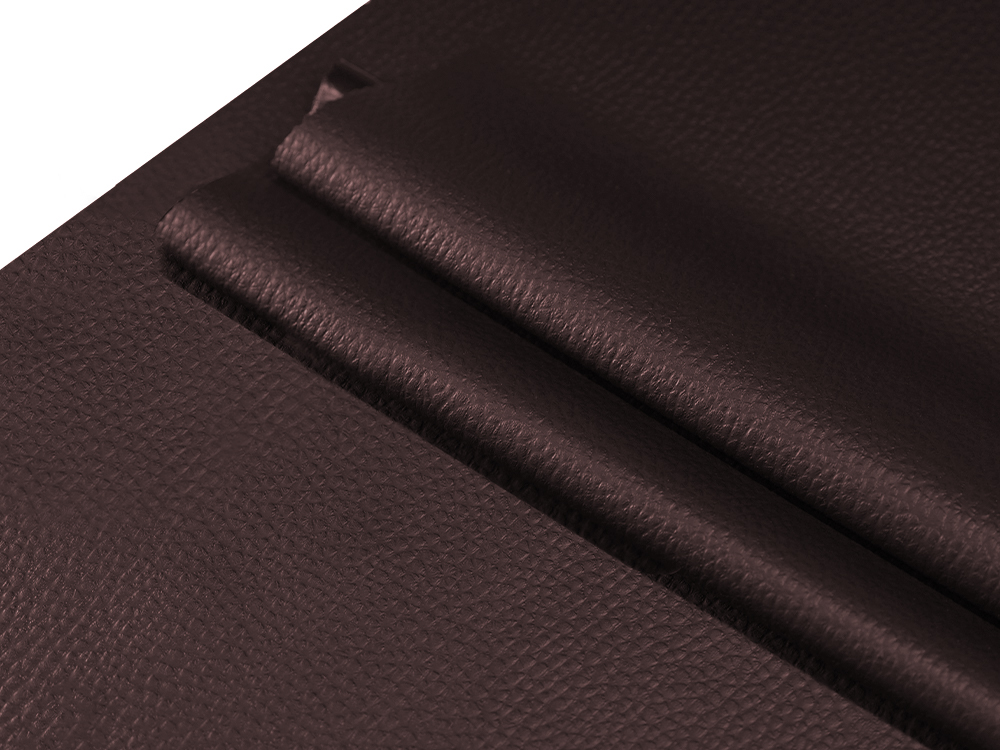

- Bag fabrics (such as PU/PVC artificial leather) require embossing via release paper to create imitation leather textures (litchi grain, crocodile grain), woven patterns, geometric designs, etc., enhancing product sophistication.

- The precision of release paper directly impacts the realism and premium feel of bag fabrics.

(2) Tactile Optimization

- Different release paper textures can adjust the softness and matte/gloss effects of bag fabrics to meet diverse style needs (e.g., matte finishes for business bags, high-gloss for fashion bags).

(3) Demolding Function

- After the PU/PVC coating cures, release paper peels off easily without damaging the material, improving production efficiency.

2. Key Application Stages in Bag Fabric Production

(1) Dry Process PU/PVC Technology (Main Application)

- Coating Stage: PU or PVC slurry is coated onto release paper and cured in an oven.

- Laminating Stage: The cured PU/PVC film is thermally pressed onto base fabrics (e.g., knitted fabric, non-woven fabric).

- Peeling Stage: After cooling, the release paper is peeled off, transferring the texture to the fabric surface.

(2) Wet Process PU Technology (for Premium Applications)

- Release paper is used in wet coagulation processes to form porous, breathable structures (suitable for sports backpacks requiring air permeability).

(3) Post-Embossing Treatment

- Some bag fabrics undergo secondary embossing (e.g., logo stamping) after formation, where release paper may assist in shaping.

3. Common Types of Release Paper for Luggage and Bags

| Type | Characteristics | Suitable Bag Types |

|---|---|---|

| High-Gloss Release Paper | Smooth surface for shiny finishes | Fashion handbags, business briefcases |

| Matte Release Paper | Fine matte surface for premium aesthetics | Luxury bags, minimalist-style 箱包 |

| Imitation Leather Release Paper | Litchi, crocodile, snake textures for 真皮质感 (real leather feel) | High-end leather bags, suitcases |

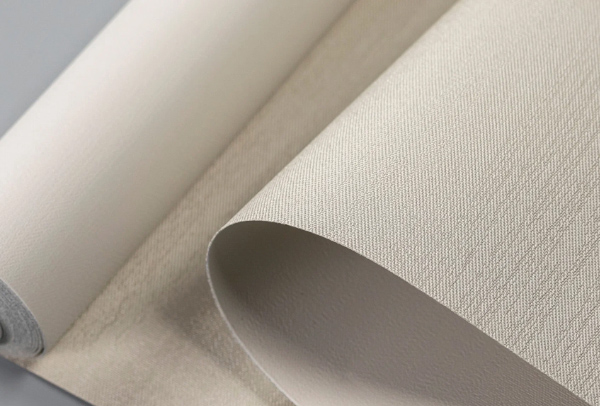

| Woven Pattern Release Paper | Imitation linen/canvas textures for casual styles | Canvas bags, backpacks |

| 3D Embossed Release Paper | Raised patterns for tactile effects (e.g., embossed logos) | Brand-customized bags, designer styles |

4. Industry Trends and Challenges

(1) Environmental Requirements

- Water-Based PU Technology: Reduced solvent use demands better water resistance from release paper.

- Recyclable Release Paper: Some enterprises use release paper reusable over 10 times to cut costs and waste.

(2) Personalized Customization

- The rise of small-batch digital embossing requires release paper to support quick pattern changes for fast-fashion bag brands.

(3) High-Performance Demands

- Bag fabrics need abrasion, scratch, and stain resistance, requiring release paper coatings to integrate special additives (e.g., silicone-modified agents).

5. Comparison: Release Paper vs. Other Texturing Processes

| Process | Advantages | Disadvantages | Application Scenarios |

|---|---|---|---|

| Release Paper Embossing | Fine textures, customizable, high fidelity | Higher cost, paper replacement needed | Premium bags, brand customization |

| Steel Roller Embossing | Suitable for mass production, low cost | Limited patterns, inflexible | Affordable bags, standardized production |

| Digital Inkjet Embossing | No plate-making, quick pattern changes | High equipment cost, unproven abrasion resistance | Niche designs, limited-edition bags |

6. Future Development Directions

- More Durable Release Paper: Increased reuse cycles (e.g., 20+ times) to reduce costs.

- Intelligent Texture Design: Integration with 3D printing for complex surface effects.

- Eco-Friendly Release Paper: Use of degradable materials compliant with EU REACH and other environmental regulations.

Conclusion

Release paper’s core value in the luggage and bag industry lies in enhancing fabric texture and enabling design differentiation, directly impacting the visual and tactile experience of bags. As consumer demands grow for personalized, eco-friendly, and high-quality products, release paper technology is evolving toward higher realism, sustainability, and performance. Manufacturers should select appropriate release paper based on bag positioning (luxury, fast fashion, functional) and optimize processes to balance cost and quality.

English

English 中文简体

中文简体