Release paper plays a vital role in the PU artificial leather (polyurethane artificial leather) industry, mainly used in the production process of the transfer method (dry process). Its core role is to serve as a temporary carrier to help the PU coating form specific surface textures and properties, and finally, after peeling, an artificial leather product with the desired appearance and hand feeling is obtained. The following are the specific applications and key points of release paper in the PU artificial leather industry:

1. Core Functions of Release Paper

-

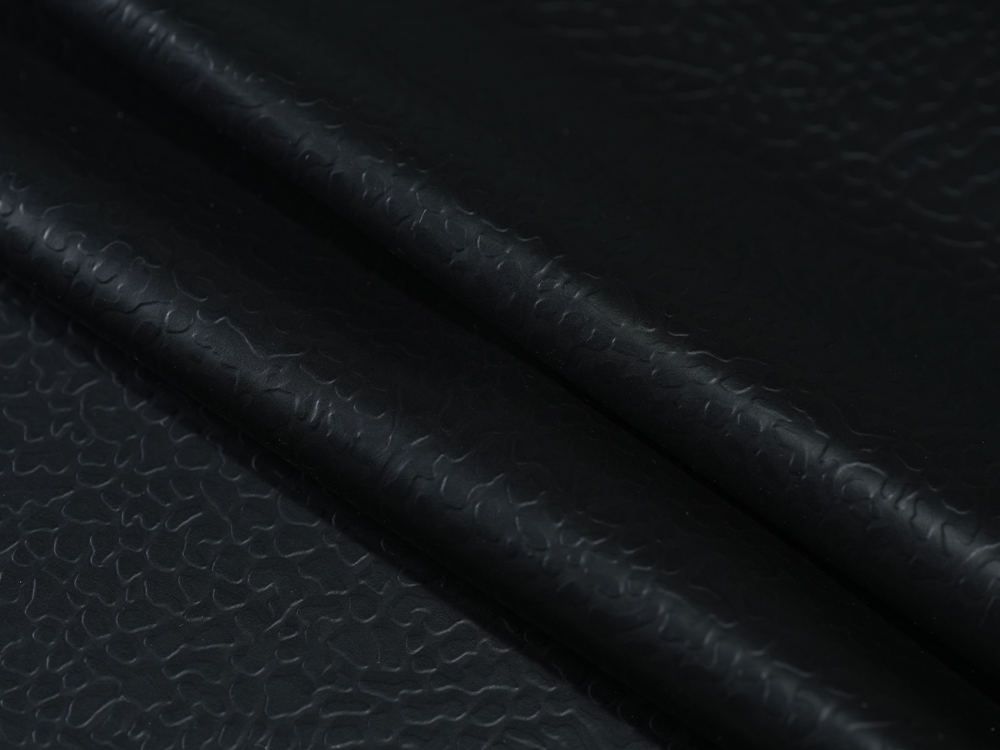

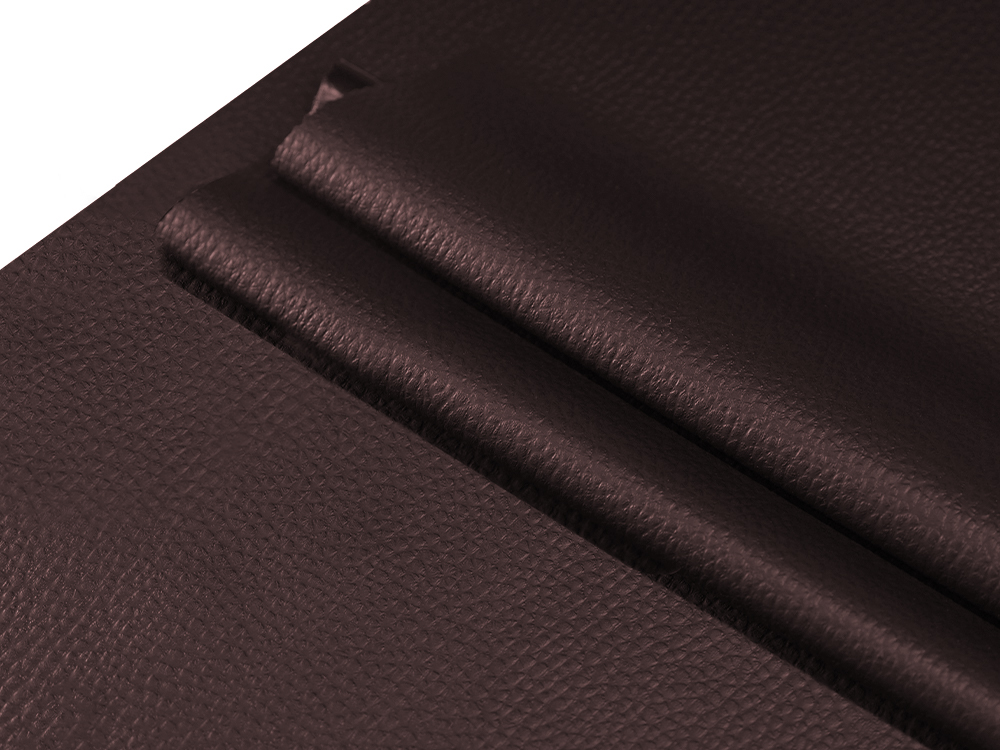

Texture Transfer

The surface of the release paper is pre-designed with textures (such as imitation leather texture, litchi texture, cloth texture, geometric patterns, etc.). Through the coating process, the PU slurry is attached to the release paper. After curing and peeling, the texture is transferred to the surface of the PU. -

Demolding Effect

The silicone oil coating of the release paper ensures that the PU layer can be easily peeled off after curing without damaging the surface effect. -

Surface Flatness Control

High-precision release paper can ensure that the surface of the PU layer is smooth and free of defects.

2. Key Application Stages in PU Artificial Leather Production

-

Coating Stage

The release paper is uniformly coated with PU resin slurry (which may contain solvents, additives, etc.) on its surface through a coating machine.

The slurry is cured by heating in an oven to form a PU film layer. -

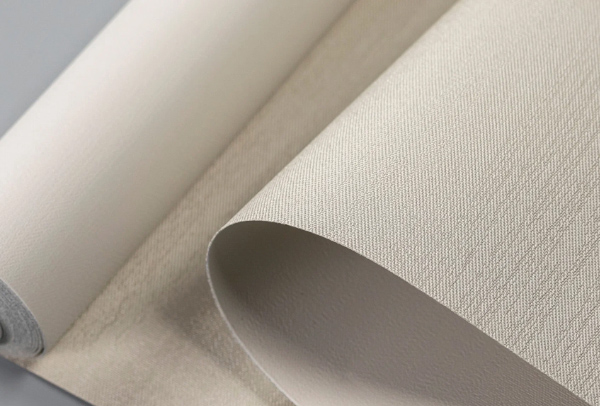

Laminating Stage

The PU film layer is thermally pressed and laminated with substrates (such as knitted fabric, non-woven fabric, woven fabric, etc.). -

Peeling Stage

After cooling, the release paper is peeled off from the PU layer, and its surface texture is perfectly replicated onto the PU artificial leather.

The release paper can be recycled and reused (usually 5-10 times, depending on the paper quality and process conditions).

3. Types and Selection of Release Paper

Common release papers used in the PU artificial leather industry mainly include:

| Type of Release Paper | Characteristics | Application Scenarios |

|---|---|---|

| Glassine Release Paper | High temperature resistance, high strength | Suitable for high-precision textures |

| CCK Release Paper (Clay Coated Paper) | Fine surface | Commonly used for high-end imitation leather textures |

| PE (Polyethylene) Release Paper | Good water resistance | Suitable for special environments |

| Embossed Release Paper | Three-dimensional textures formed by embossing or chemical etching (e.g., crocodile skin texture, snake skin texture, etc.) | For special texture requirements |

Selection Criteria:

- Texture design requirements (resolution, three-dimensional effect).

- Production process (temperature, solvent type).

- Cost and number of reuse times.

4. Industry Advantages and Challenges

-

Advantages

The release paper process can achieve highly simulated natural leather textures, enhancing product added value.

High production flexibility, allowing quick changes in texture designs to adapt to market trends.

Under the environmental protection trend, some release papers can be recycled, reducing waste. -

Challenges

High cost of release paper (especially imported high-end paper), affecting production costs.

Texture wear or contamination may occur during repeated use, requiring strict quality control.

Solvent-based PU coating processes have strict requirements for the chemical resistance of release paper.

5. Environmental Protection and Innovation Trends

-

Water-based PU Process

The promotion of environmentally friendly water-based PU resins requires release paper to have better water resistance. -

Solvent-free Process

Puts forward higher requirements for the temperature resistance and demolding performance of release paper. -

Sustainable Release Paper

Development of biodegradable or higher-cycle-release papers, such as the "green release paper" launched by some enterprises.

6. Downstream Application Fields

PU artificial leather is widely used in:

- Footwear (sports shoes, casual shoes)

- Furniture/automotive interiors (sofas, seats)

- Luggage and apparel (handbags, clothing)

- Electronic accessories (mobile phone cases, headphone covers)

The texture diversity of release paper directly determines the market competitiveness of these terminal products.

Conclusion

Release paper is a key auxiliary material for the PU artificial leather industry to achieve highly simulated textures and surface functions, and its performance directly affects product quality and production efficiency. With the industry's trend towards environmental protection and high performance, the technological innovation of release paper (such as more durable coatings and degradable materials) will become a future focus. Enterprises need to reasonably select the type of release paper and optimize process parameters according to product positioning and process requirements to balance cost and quality.

English

English 中文简体

中文简体