Submit feedback

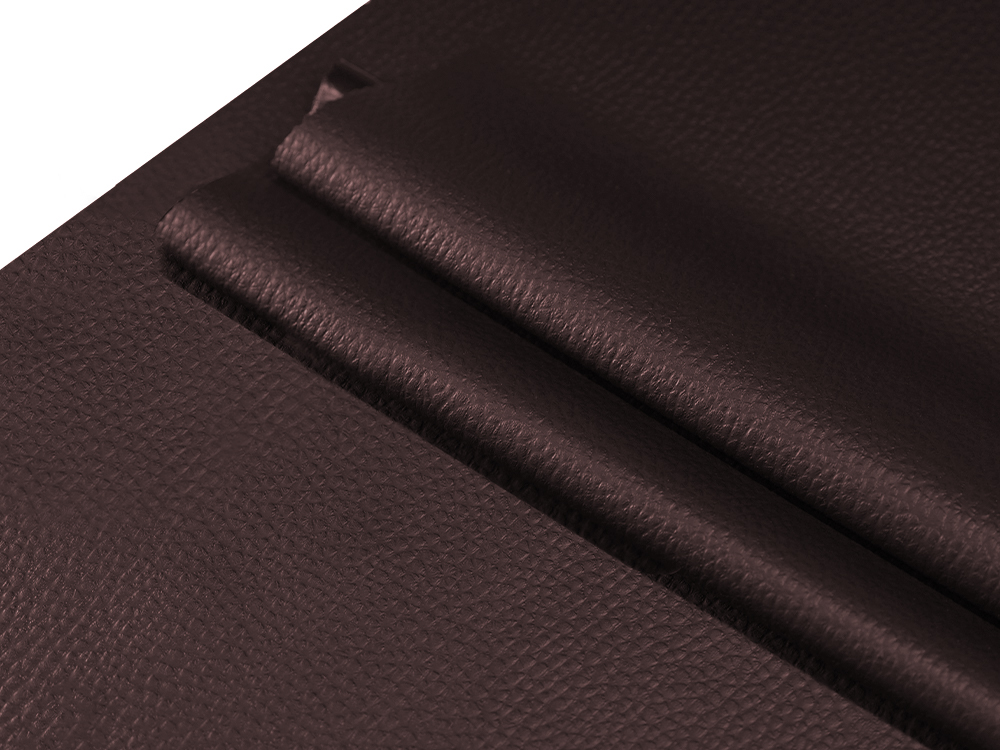

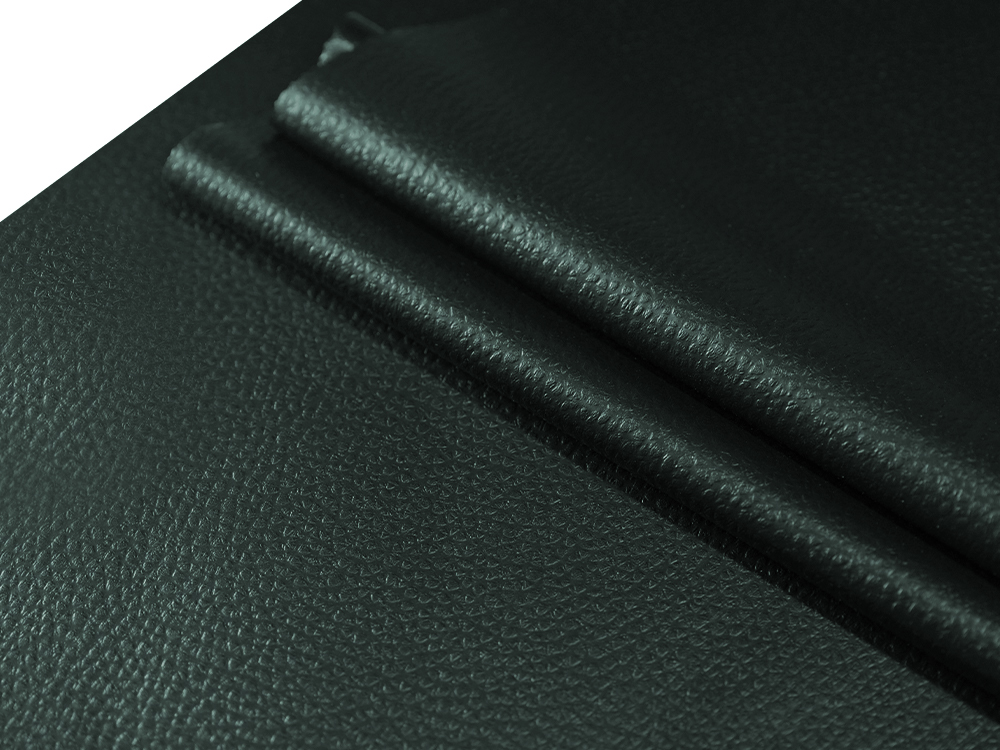

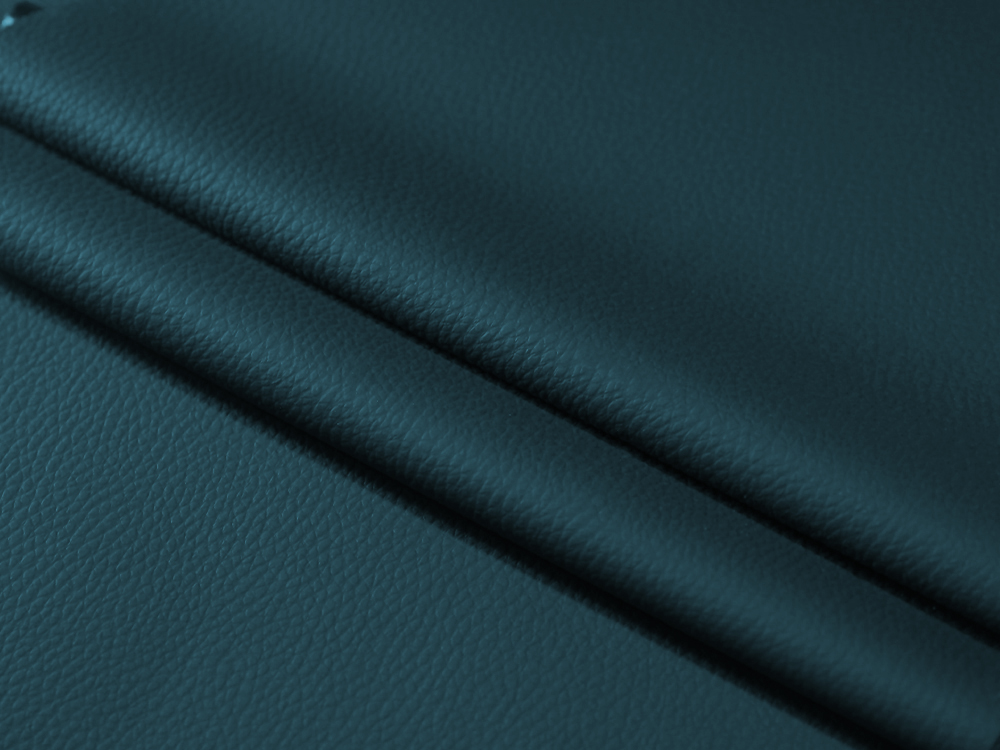

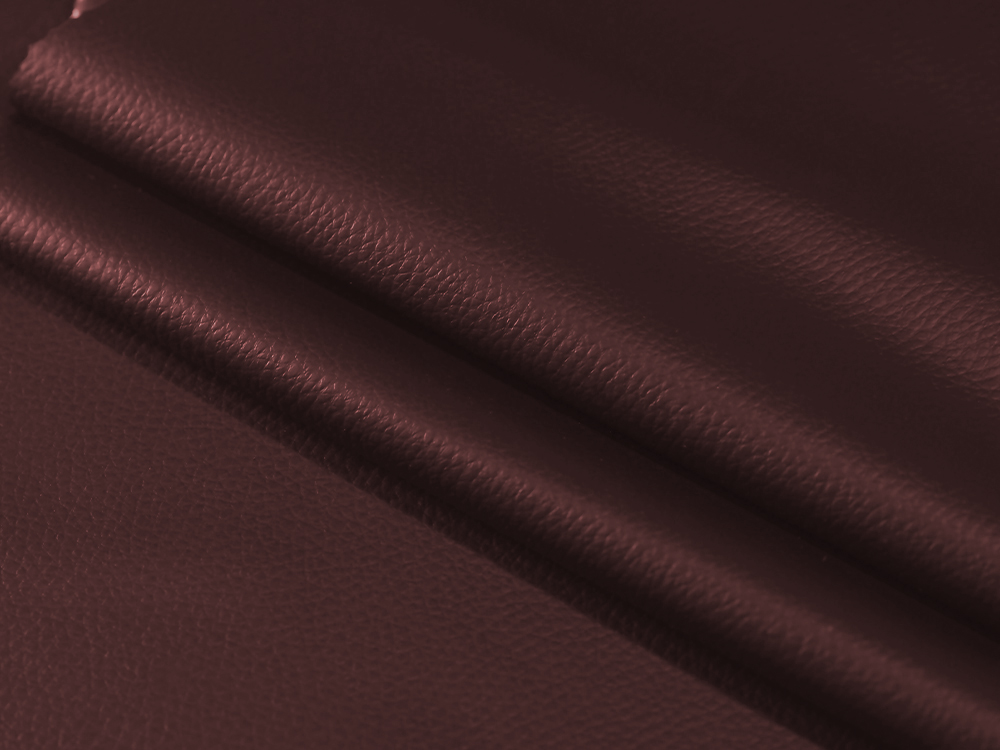

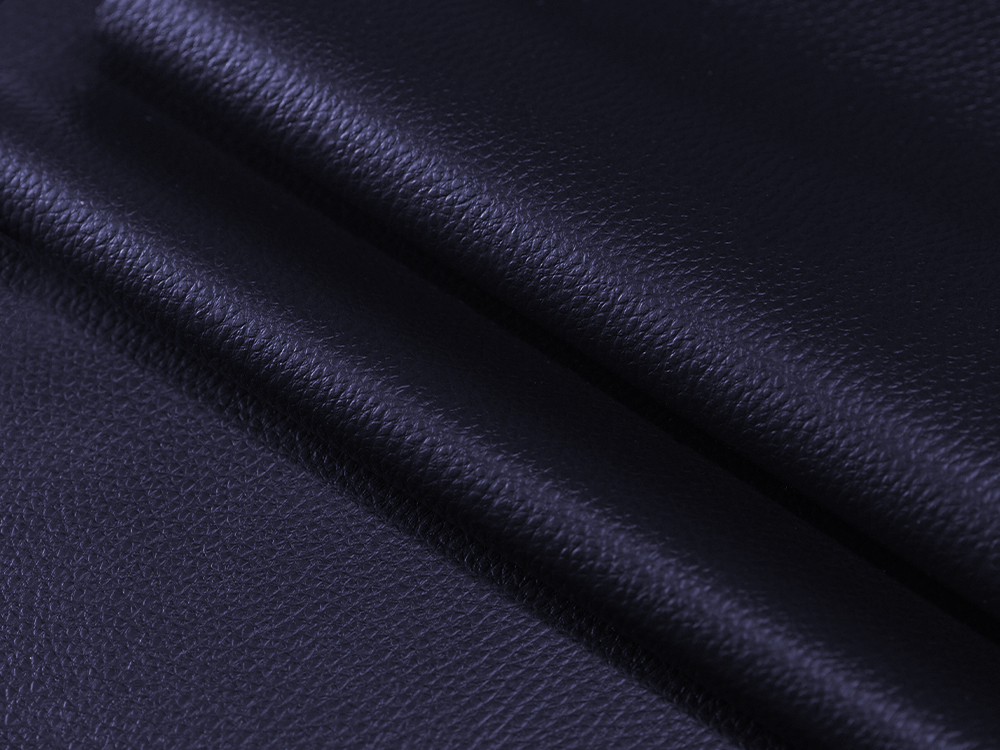

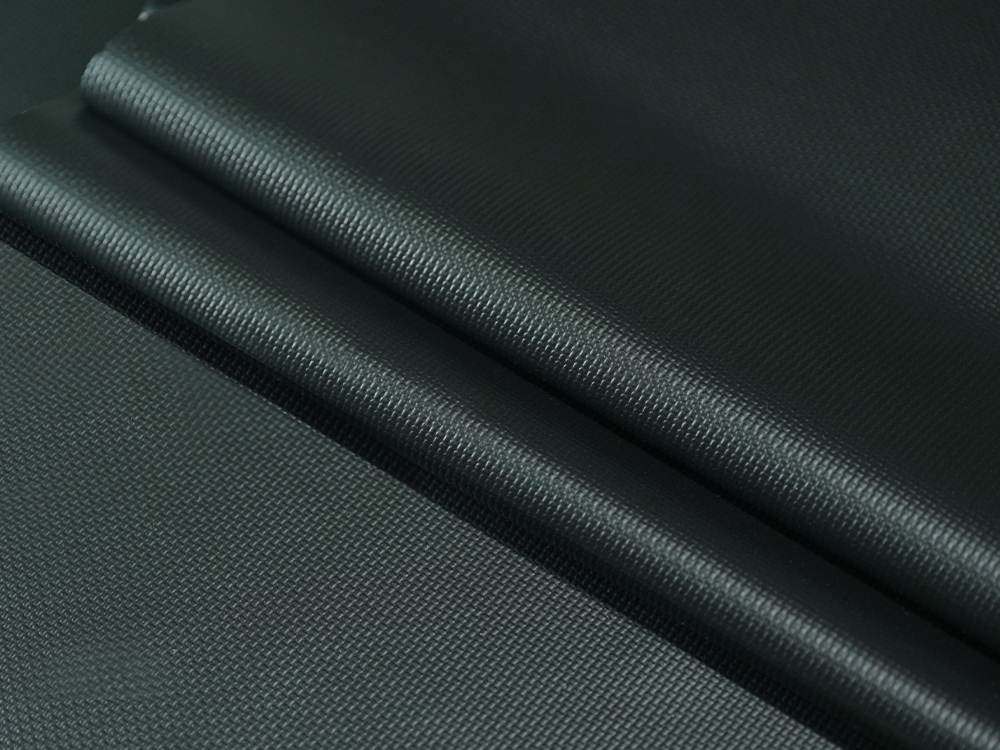

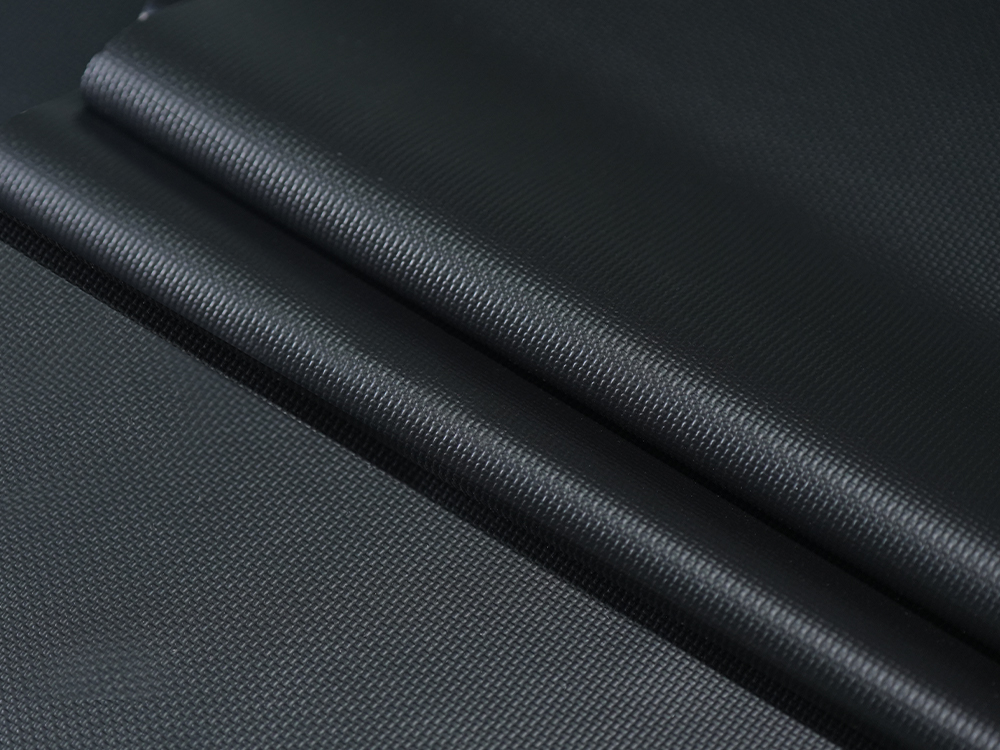

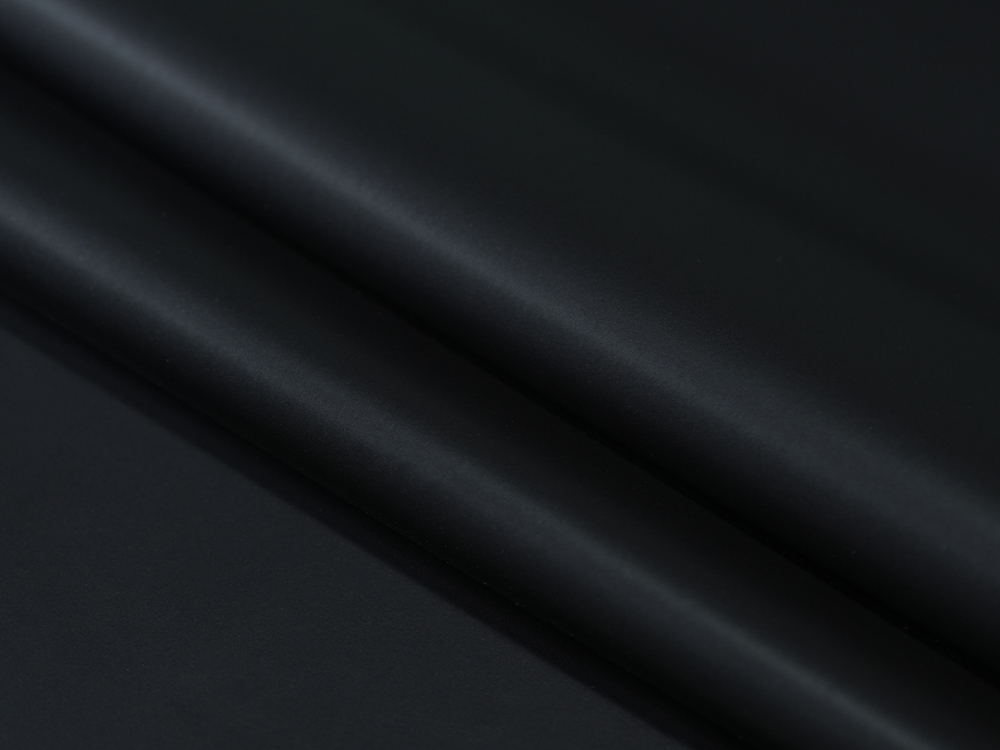

Custom Release Paper for Sofa Manufacturers

Industry Knowledge Extension

How does release paper for sofa compare with smooth release film in performance?

In the production of synthetic leather and upholstered furniture, the choice of release materials plays a critical role in determining the final product’s quality. Release paper for sofa and smooth release film are two widely used options, each offering unique performance characteristics. Understanding their differences and suitability for various industrial applications is essential for manufacturers seeking optimal results.

Overview of release paper for sofa and smooth release film

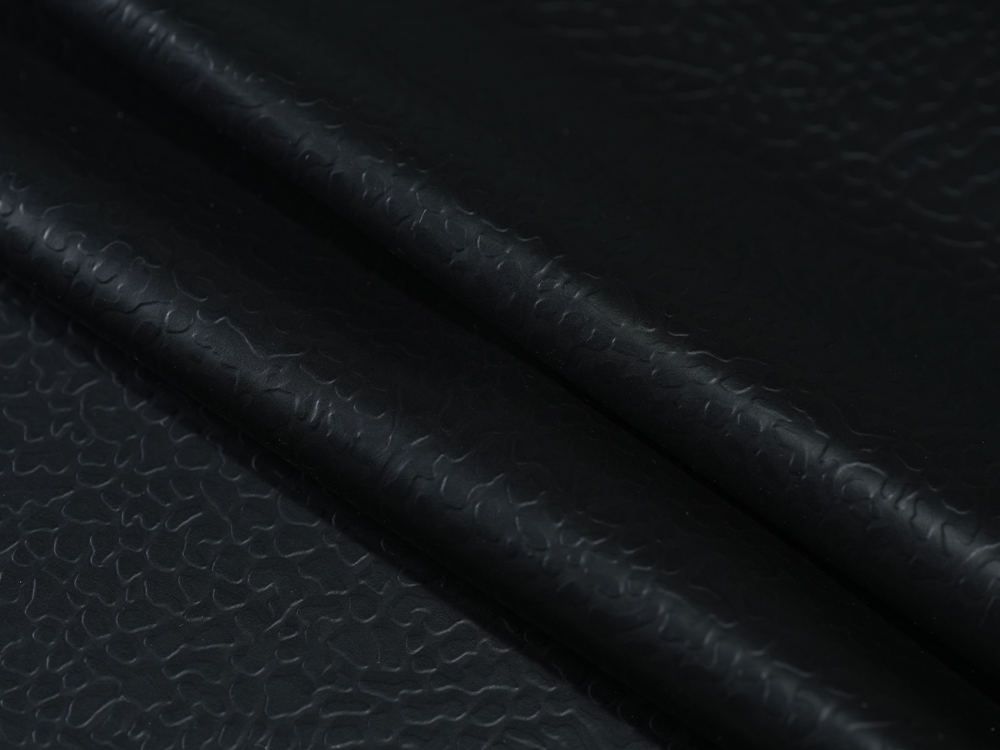

Release paper for sofa is a specialized paper designed to facilitate the separation of coated synthetic leather from molds or rollers. Its primary function is to ensure smooth release during high-temperature processes while maintaining the integrity of the coated surface. On the other hand, smooth release film is typically a polymer-based material that provides a non-stick surface for leather, foam, or synthetic coatings.

While both materials aim to prevent adhesion during production, their physical structures, thermal resistance, and surface properties differ significantly. Release paper for sofa generally exhibits higher rigidity, superior dimensional stability, and precise surface textures, which make it suitable for embossing and pattern transfer processes. Smooth release film, however, offers flexibility and excellent conformability, which is advantageous for curved surfaces or complex shapes.

Material composition and manufacturing considerations

The performance of release paper for sofa largely depends on its base paper, release coating, and surface treatment. Manufacturers use high-temperature-resistant base papers combined with silicone or fluoropolymer coatings to achieve the desired release properties. The coating thickness and uniformity influence the ease of release, surface gloss, and matte levels.

Smooth release film is usually composed of polyethylene, polypropylene, or other thermoplastic materials. Its surface is treated with anti-adhesive agents to prevent bonding with polyurethane (PU) or polyvinyl chloride (PVC) coatings. The material’s flexibility and chemical resistance make it ideal for applications where repeated bending or shaping occurs.

The manufacturing process of release paper for sofa involves precise coating control, advanced drying techniques, and stringent quality testing. Consistency in thickness, smoothness, and release performance is crucial to avoid defects in the final product. High-quality release paper can accommodate embossing, hot stamping, and high-temperature PU or PVC processes without compromising surface quality.

Performance comparison

1. Thermal resistance

Release paper for sofa exhibits excellent thermal stability, making it suitable for high-temperature PU and PVC coating processes. It maintains dimensional stability and prevents deformation even under prolonged heating, which is critical for consistent surface texture and gloss. Smooth release film has moderate thermal resistance; while it performs well in low- to medium-temperature processes, it may soften or shrink under extreme heat, potentially affecting product quality.

2. Surface finish and texture reproduction

A key advantage of release paper for sofa is its ability to reproduce intricate surface textures. Manufacturers can achieve precise embossing patterns, subtle matte effects, or glossy finishes by selecting release paper with appropriate coating formulations. Smooth release film provides a smooth surface, which is ideal for basic release functions but may not accurately transfer complex patterns or textures.

Table: Comparison of release paper for sofa and smooth release film performance

| Feature | Release Paper for Sofa | Smooth Release Film |

|---|---|---|

| Thermal resistance | High, suitable for high-temperature processes | Moderate, limited by polymer softening |

| Surface texture reproduction | Excellent, supports embossing and patterns | Limited, best for smooth finishes |

| Flexibility | Moderate, maintains shape and rigidity | High, conforms to complex surfaces |

| Adhesion prevention | Consistent, even under high heat | Effective, but may vary under heat |

| Reusability | Multiple uses with consistent results | Limited by mechanical wear |

3. Adhesion and anti-stick performance

Both materials prevent bonding during coating and curing. Release paper for sofa provides consistent anti-adhesion across different synthetic leather formulations, minimizing surface defects such as bubbles, scratches, or incomplete release. Smooth release film is effective for flexible coatings and small-scale applications but may require additional support or handling precautions in high-volume industrial processes.

4. Production efficiency and cost considerations

Smooth release film offers advantages in rapid handling and low initial investment. Its lightweight and flexible nature simplify storage and transportation. Release paper for sofa, while slightly higher in cost, reduces defects, enhances surface consistency, and supports high-temperature or high-speed production environments. Manufacturers focusing on large-scale synthetic leather production often find release paper more reliable and cost-effective over time due to reduced waste and rework.

Application scenarios

Release paper for sofa is commonly used in the following scenarios:

- High-temperature PU or PVC coating of synthetic leather for furniture and car interiors.

- Embossed or patterned surfaces where precise texture transfer is required.

- Anti-fingerprint or anti-scratch surface treatments.

Smooth release film is suitable for:

- Low- to medium-temperature coating processes.

- Flexible substrates or items with complex shapes.

- Short-term or small-batch production where pattern precision is less critical.

Quality control and technical support

The consistency and reliability of release paper for sofa are ensured through advanced testing and production monitoring. Modern manufacturers employ pilot coating machines, analytical instruments, and strict cycle time controls to maintain product standards. For urgent or customized requirements, flexible scheduling and tailored development services are often provided to meet specific gloss levels, embossing patterns, or dimensions.

Technical support from manufacturers includes guidance on:

- Correct selection of release materials for different coating types.

- Optimization of thermal and pressure settings to prevent surface defects.

- Troubleshooting adhesion issues or surface irregularities.

These measures enhance operational efficiency and product quality, making release paper a preferred choice for professional sofa leather production.

Advantages of release paper over smooth release film

Release paper for sofa offers several advantages in industrial applications:

- High thermal resistance ensures stable performance under prolonged heating.

- Accurate pattern transfer allows for diverse aesthetic finishes.

- Consistent anti-adhesion reduces waste and minimizes surface defects.

- Customizable specifications in width, thickness, and coating type support tailored production.

- Durability and reusability enable multiple production cycles without compromising quality.

Smooth release film, while convenient and flexible, cannot always match the precision, thermal stability, or texture reproduction provided by high-quality release paper.

Selecting the right release material

Choosing between release paper for sofa and smooth release film depends on the specific production requirements:

- Production temperature: High-temperature PU or PVC processes favor release paper.

- Surface texture requirements: Embossed or patterned surfaces require release paper for accurate reproduction.

- Scale of production: Large-scale operations benefit from the durability and consistency of release paper.

- Flexibility and shape complexity: Smooth release film is advantageous for intricate shapes or small-batch production.

Manufacturers should evaluate cost-effectiveness, defect rates, and after-sales support when making the selection. Comprehensive technical support from the release paper supplier ensures that production challenges are efficiently addressed.

Conclusion

Release paper for sofa and smooth release film each have distinct roles in synthetic leather production. While smooth release film provides flexibility and ease of handling, release paper delivers superior thermal resistance, texture reproduction, and consistent anti-adhesion performance. For high-quality furniture or automotive leather, release paper often proves to be the more reliable and efficient option.

By understanding the differences in material properties, production performance, and application scenarios, manufacturers can make informed decisions, optimize production efficiency, and ensure the highest quality of synthetic leather surfaces.

FAQs

Q1: What is the main difference between release paper for sofa and smooth release film?

A1: Release paper offers high thermal resistance and precise pattern reproduction, while smooth release film is flexible and suited for low- to medium-temperature processes.

Q2: Can release paper for sofa be reused?

A2: Yes, high-quality release paper can be used multiple times without losing anti-adhesion or surface consistency.

Q3: What widths are available for release paper for sofa?

A3: Typically, widths range from 1,600mm to 2,350mm, with adjustable specifications to meet customer requirements.

Q4: Is release paper for sofa suitable for embossed or patterned surfaces?

A4: Yes, it is specifically designed to reproduce intricate textures and patterns accurately.

Q5: How does release paper help reduce defects in synthetic leather production?

A5: By providing consistent anti-adhesion and thermal stability, it prevents surface scratches, bubbles, and incomplete release during coating and curing.

English

English 中文简体

中文简体