Submit feedback

Custom Release Paper for Shoe Sofa Leather Manufacturers

Industry Knowledge Extension

How does release paper for shoe sofa leather differ from release paper for other leather products?

In the leather industry, release paper for shoe sofa leather is a specialized material designed to meet the unique demands of producing high-quality shoe and sofa leather. Unlike standard release paper used for other leather products, this type of paper emphasizes high-temperature resistance, surface protection, and precise replication of textures and patterns. Understanding its differences from other leather release papers is critical for manufacturers seeking consistent product quality and efficient production.

The role of release paper in leather production

Release paper serves as a protective intermediary between the coating layer and the backing material during leather processing. For shoe and sofa leather, this function is particularly crucial because these products require durability, aesthetic appeal, and surface uniformity. The release paper for shoe sofa leather ensures smooth separation after PU, PVC, or other synthetic coatings are applied. This prevents surface defects such as sticking, peeling, or micro-scratches, which are more likely to occur due to the complex textures often used in shoe and sofa leather.

Key performance criteria

The essential performance characteristics of release paper for shoe sofa leather include:

- High-temperature resistance – Ensures stability during the curing process of synthetic leather coatings.

- Surface smoothness or pattern accuracy – Maintains desired texture for final leather aesthetics.

- Consistent release force – Guarantees separation without leaving residue or damaging the coating.

- Dimensional stability – Reduces deformation under heat or pressure during production.

These characteristics distinguish it from release papers used in other leather applications, where temperature, texture, and adhesion requirements may be less demanding.

Differences between shoe/sofa leather release paper and other leather release papers

The production and application requirements of release paper for shoe sofa leather often differ significantly from those used for other leather products, such as clothing leather or small accessories. These differences can be categorized into several aspects:

Thermal resistance and coating compatibility

Shoe and sofa leather typically undergo higher-temperature processes due to thicker PU or PVC layers. Therefore, release paper for shoe sofa leather must maintain its integrity under these conditions. In contrast, release papers for garments or thin leather accessories may only require moderate heat resistance, resulting in simpler formulations and lower-cost materials.

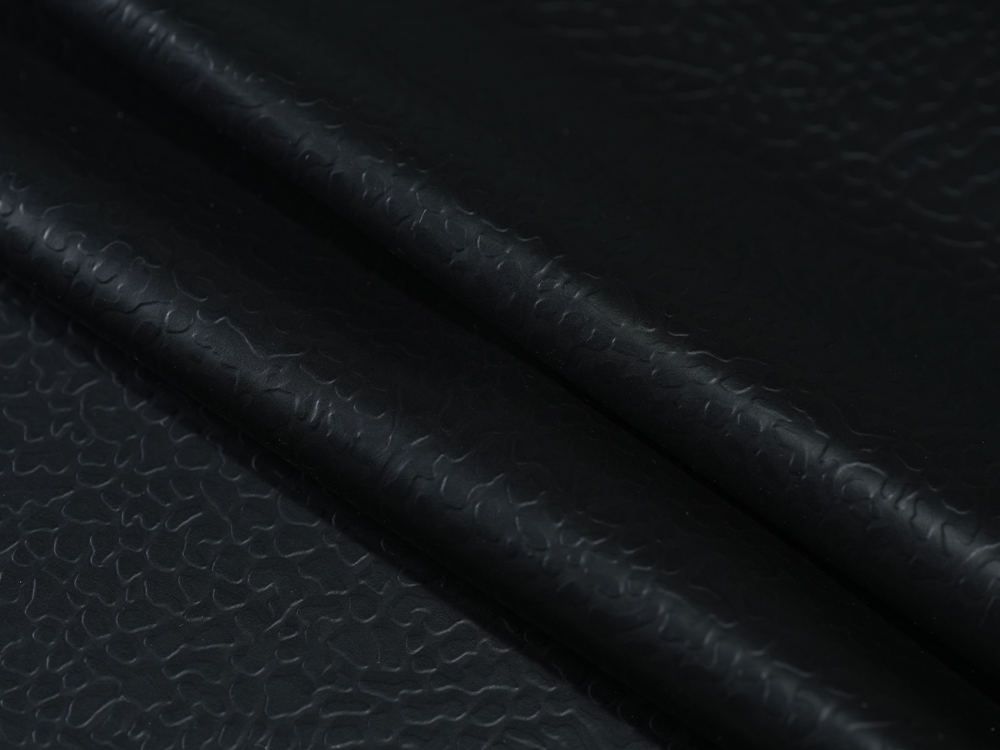

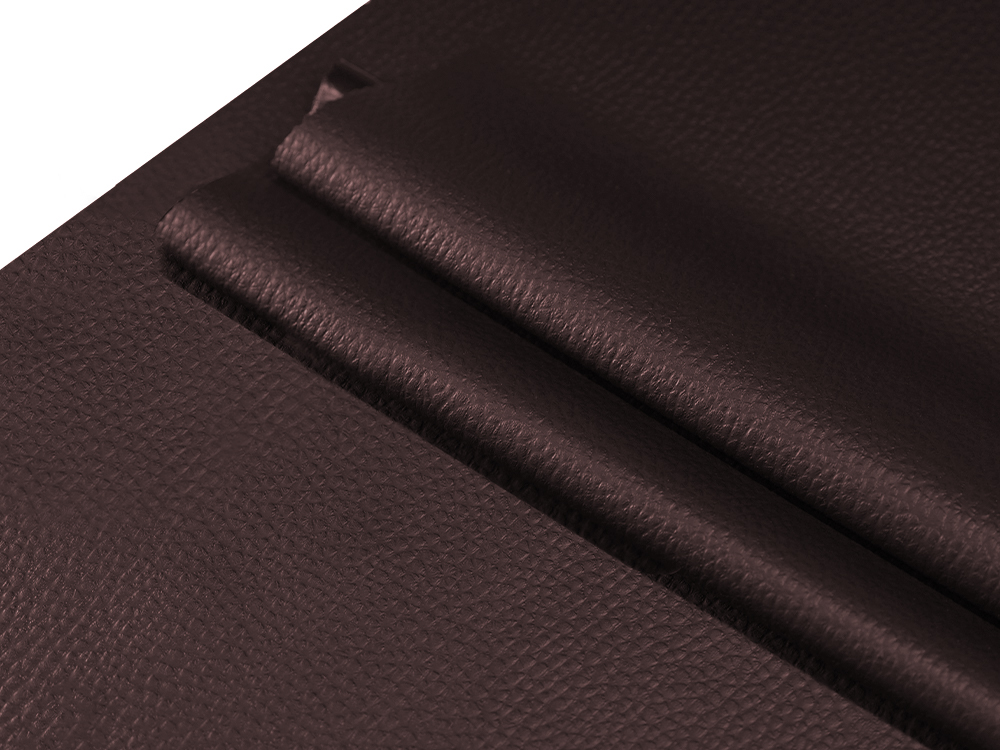

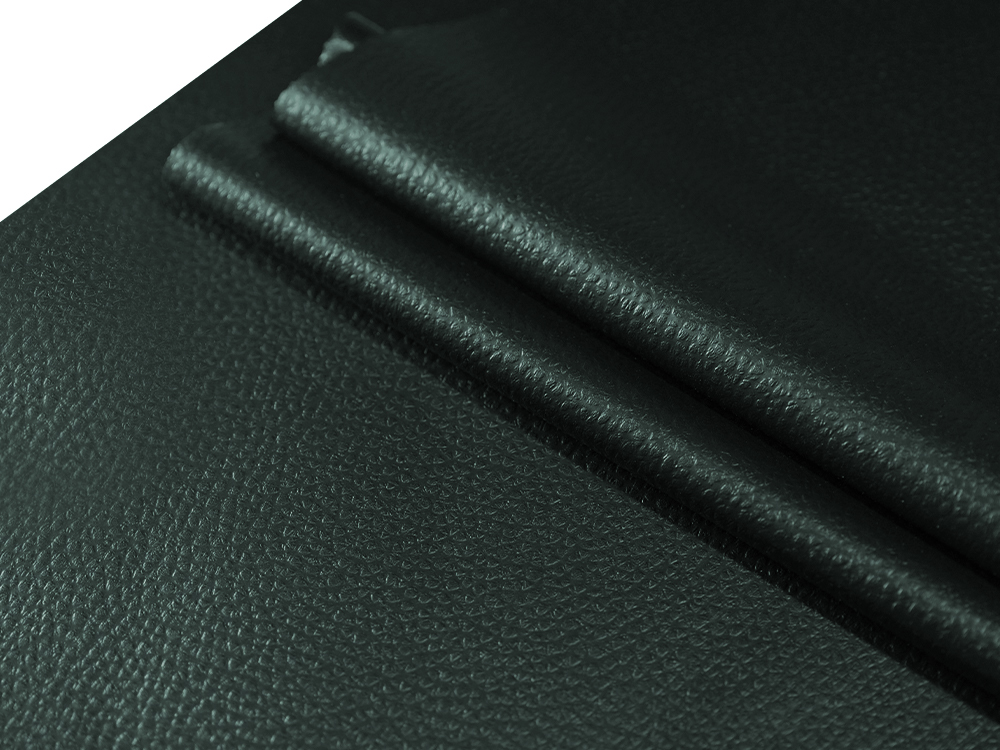

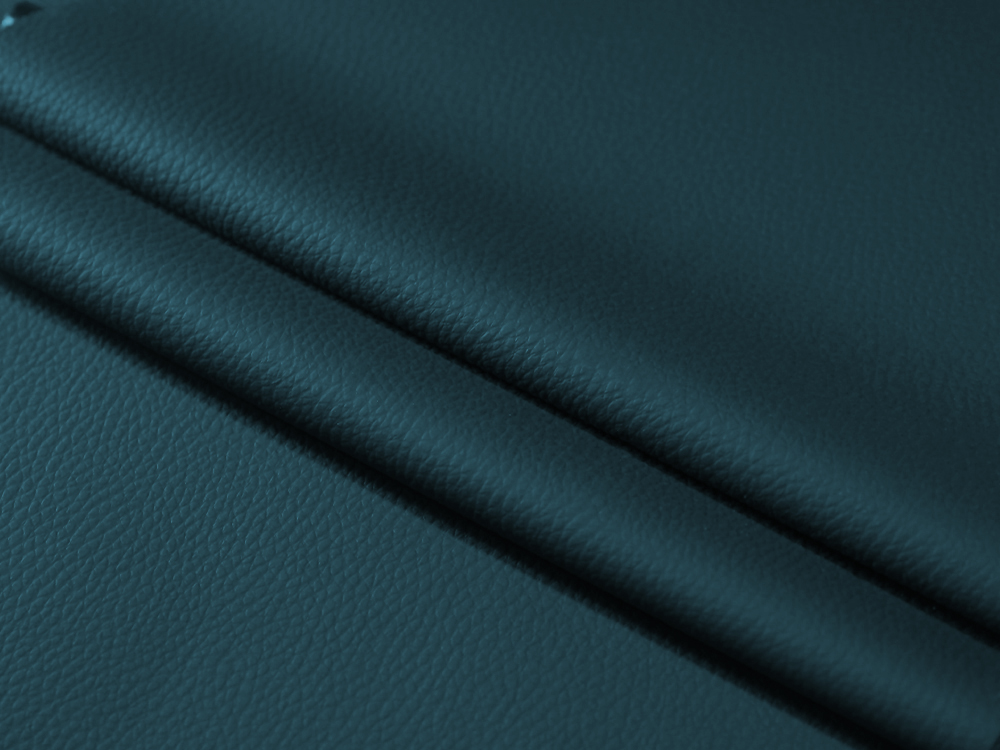

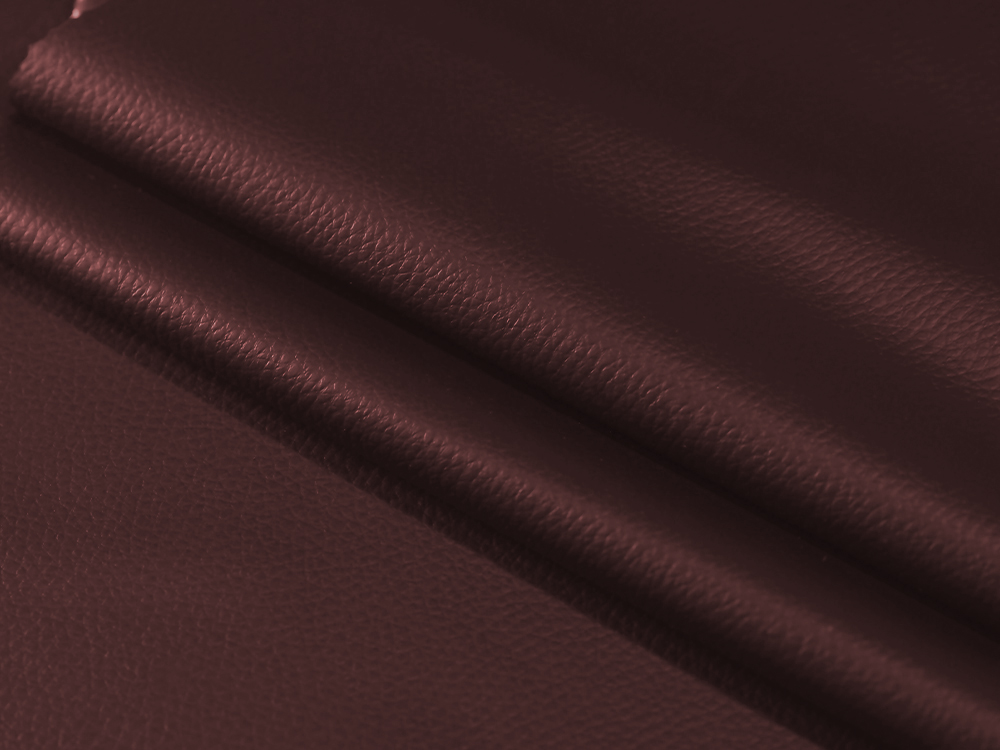

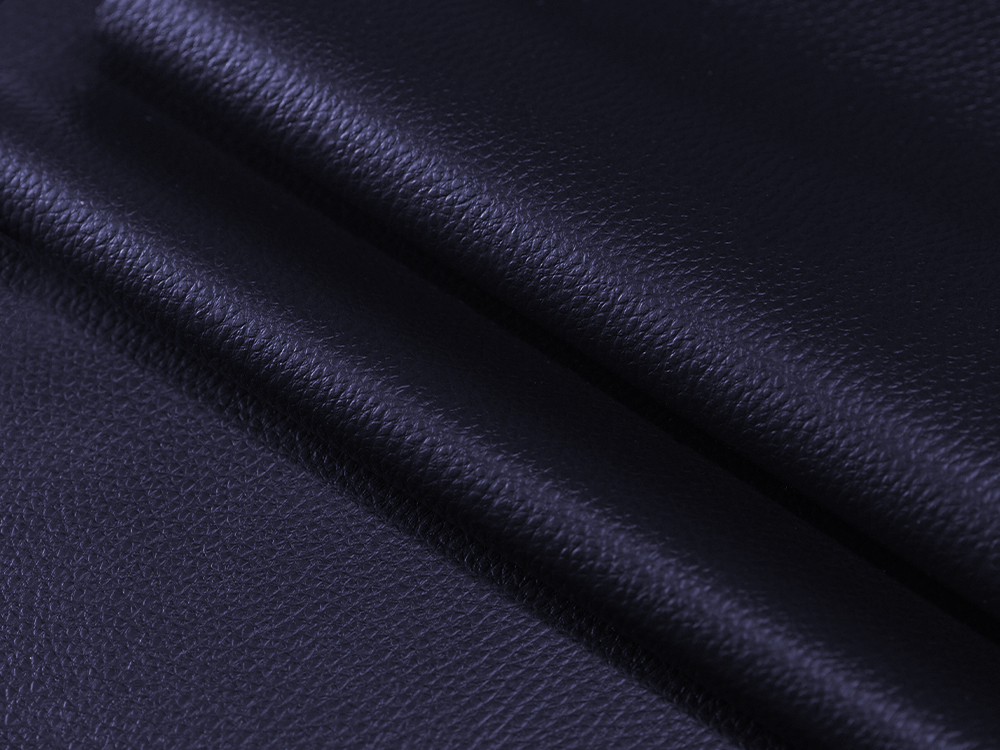

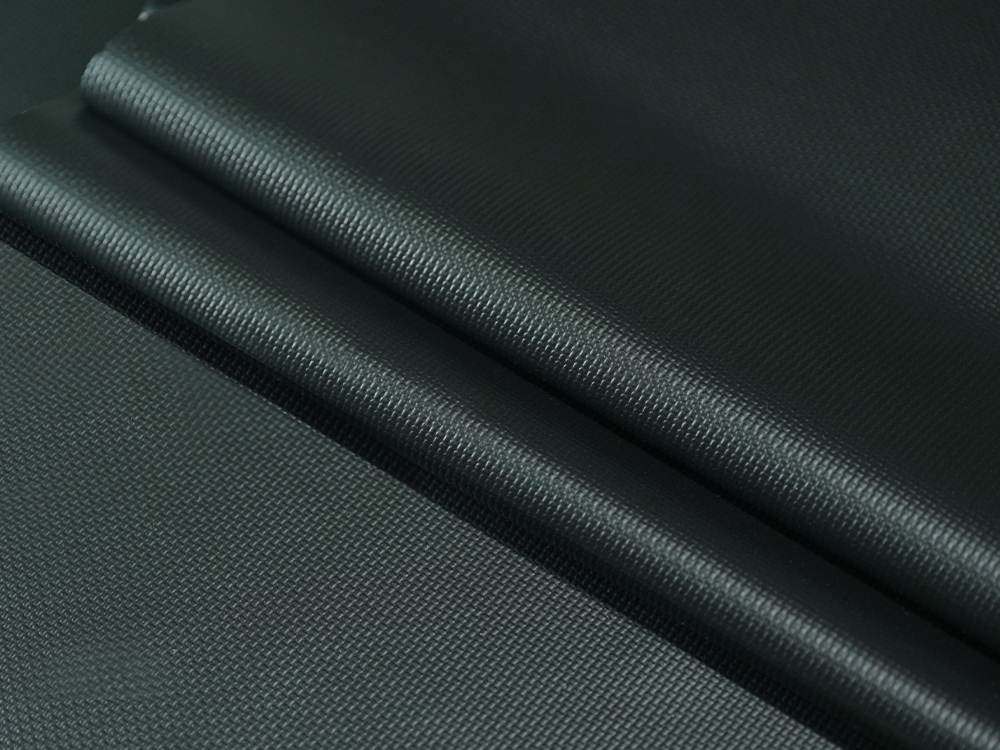

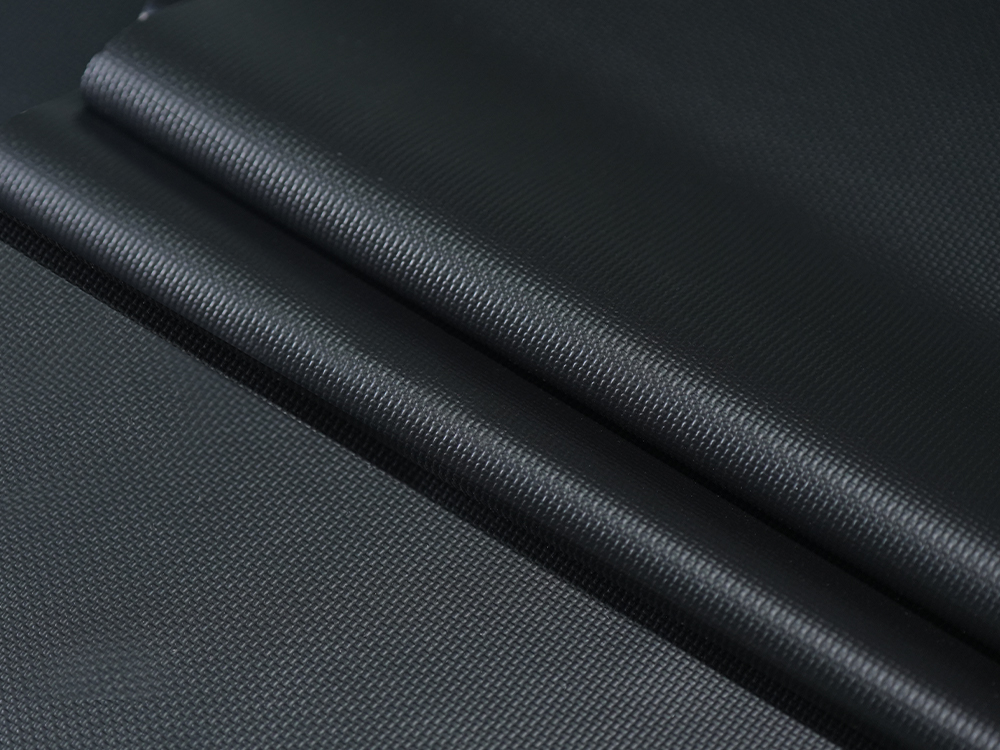

Surface pattern replication

Another major distinction lies in the ability to reproduce detailed textures. Shoes and sofas often require embossed or grainy finishes, which demand high-fidelity release paper for shoe sofa leather. Other leather products may require only a smooth or semi-gloss finish, allowing more generalized release paper solutions.

Adhesion and release force

Release paper for shoe sofa leather is formulated to balance strong coating adhesion during curing with easy release after processing. Improper release can damage the leather surface, especially on large areas like sofa panels. Meanwhile, release papers for smaller leather items can tolerate a wider range of release forces due to the reduced surface area.

Size and production efficiency

Roll widths and lengths are also differentiating factors. Release paper for shoe sofa leather is often produced in widths ranging from 1,600mm to 2,350mm to accommodate large sheets used in sofa production, while release paper for other leather products may be narrower. The paper must support high-speed production lines without compromising quality.

Durability and anti-defect properties

Shoe and sofa leathers are subject to higher wear during finishing. As such, release paper for shoe sofa leather often incorporates coatings that reduce micro-scratches, fingerprints, and dust-related defects. Release papers for smaller or decorative leather items may not require such robust protection.

Material composition and technological considerations

Release paper for shoe sofa leather is generally manufactured using high-quality base papers coated with silicone or other heat-resistant compounds. These coatings provide controlled adhesion and easy release. Key technological considerations include:

- Coating thickness: Affects release performance and surface gloss/matte finish.

- Silicone quality: High-performance silicones enhance temperature tolerance and reduce sticking.

- Base paper selection: Thicker base papers provide dimensional stability for large leather sheets.

Table: Comparison of release paper properties for different leather products

| Leather Product Type | Thermal Resistance | Surface Pattern Fidelity | Release Force Control | Roll Width Range |

|---|---|---|---|---|

| Shoe/Sofa Leather | High | High | Precise | 1600-2350mm |

| Garment Leather | Moderate | Medium | Flexible | 1000-1500mm |

| Small Leather Accessories | Moderate | Low-Medium | Tolerant | 800-1200mm |

| Decorative Leather Products | Moderate | Medium-High | Precise | 1200-1800mm |

This comparison highlights why selecting the appropriate release paper is critical for each leather application.

Manufacturing insights

Leading manufacturers of release paper for shoe sofa leather focus on integrating R&D, production, and quality assurance to deliver high-performance solutions. For instance, companies such as Anhui Honghuan New Material Technology Co., Ltd. emphasize:

- Advanced pilot coating and testing equipment to ensure consistent quality.

- Automated and semi-automated production lines for high output and efficiency.

- Flexible customization for gloss levels, EMB designs, and roll specifications.

- Rapid-response after-sales support to address urgent production needs.

Such manufacturing practices ensure the reliability and stability of each sheet of release paper for shoe sofa leather, contributing to better product outcomes.

Application benefits

Using appropriately engineered release paper for shoe sofa leather provides several advantages in leather production:

- Reduced risk of surface defects during high-temperature PU or PVC curing.

- Precise replication of textures and patterns, enhancing aesthetic appeal.

- Stable production processes due to consistent release force and dimensional stability.

- Improved operational efficiency through compatibility with automated production lines.

These benefits are particularly important in large-scale sofa production, where surface uniformity and defect-free finishes are paramount.

Selecting the right release paper for your production

When choosing release paper for shoe sofa leather, manufacturers should consider:

- Temperature tolerance matching the coating and curing process.

- Desired surface finish (matte, semi-gloss, or glossy) and texture fidelity.

- Roll width and length suited to production line requirements.

- Supply chain reliability to ensure continuous production without delays.

Ensuring these factors are met can significantly improve product quality and reduce production waste.

Conclusion

Release paper for shoe sofa leather differs from other leather release papers in several critical ways, including thermal resistance, surface fidelity, release force control, and roll dimensions. Selecting the right release paper is essential for achieving defect-free, high-quality leather products, particularly for shoes and sofas where large surfaces and intricate textures are involved. Manufacturers should rely on specialized, high-performance release paper designed for these applications to ensure consistency, efficiency, and superior end-product quality.

FAQs

Q1: Can release paper for shoe sofa leather be used for garment leather?

A1: While technically possible, it is not recommended due to higher cost and excessive thermal resistance that may be unnecessary for garments.

Q2: What thickness options are available for release paper for shoe sofa leather?

A2: Typically, roll widths range from 1,600mm to 2,350mm with adjustable thicknesses to accommodate different leather coating requirements.

Q3: How does release paper prevent scratches and fingerprints on leather surfaces?

A3: Coatings on the paper provide a protective barrier and smooth separation, reducing contact friction and surface defects.

Q4: Are custom embossing or texture designs possible?

A4: Yes, manufacturers offer tailored development services to meet specific gloss levels, textures, and EMB designs.

Q5: How quickly can release paper for shoe sofa leather be delivered for urgent orders?

A5: Leading manufacturers maintain flexible scheduling and logistics to meet tight deadlines without compromising quality.

English

English 中文简体

中文简体