Submit feedback

Custom Release Paper for Luggage Leather Manufacturers

Industry Knowledge Extension

How does release paper for luggage leather perform under high-temperature PU or PVC coating conditions?

In the modern leather manufacturing industry, the performance of release paper for luggage leather plays a crucial role in achieving high-quality synthetic leather products. As luggage production increasingly relies on PU (polyurethane) and PVC (polyvinyl chloride) coatings, manufacturers must ensure that the release paper used can withstand high-temperature environments without compromising surface finish, texture, or adhesion properties. Understanding the performance characteristics of release paper under these conditions is essential for maintaining efficiency, product consistency, and overall operational quality.

Company Overview and Industry Context

Anhui Honghuan New Material Technology Co., Ltd is a professional manufacturer specializing in high-temperature release paper for synthetic leather. The company operates with an integrated model encompassing research and development, production, and sales. With extensive experience in producing release paper for luggage leather, coated paper, and other specialty packaging materials, the company focuses on delivering products that meet strict quality and performance standards. Equipped with advanced production lines and testing facilities, Anhui Honghuan ensures reliable supply, rapid delivery, and customized solutions for diverse industrial applications.

The development of high-temperature release paper has been a pivotal advancement for industries utilizing PU and PVC coatings. This innovation enables leather manufacturers to produce synthetic leather that maintains consistent texture, color, and gloss, even under demanding thermal processing conditions.

High-Temperature Coating Processes in Leather Production

In synthetic luggage leather manufacturing, PU and PVC coatings are applied at elevated temperatures to create durable, flexible, and aesthetically appealing surfaces. These coatings are often applied through calendaring, hot pressing, or lamination processes. The typical temperature range for PU coating can reach 150–200°C, while PVC coatings may require 180–220°C. Under such conditions, release paper for luggage leather must resist deformation, prevent sticking, and maintain pattern fidelity.

Failure to select an appropriate release paper can result in surface defects, uneven textures, or adhesion problems, leading to increased production waste and reduced operational efficiency.

Material Properties of High-Temperature Release Paper

The performance of release paper for luggage leather under high-temperature PU or PVC coating conditions depends on several key material properties:

- Thermal Resistance: High-temperature release paper must maintain dimensional stability at elevated temperatures, ensuring that embossing patterns and textures remain intact.

- Coating Compatibility: The release coating on the paper must be compatible with PU and PVC resins, preventing chemical reactions that could compromise surface smoothness or release performance.

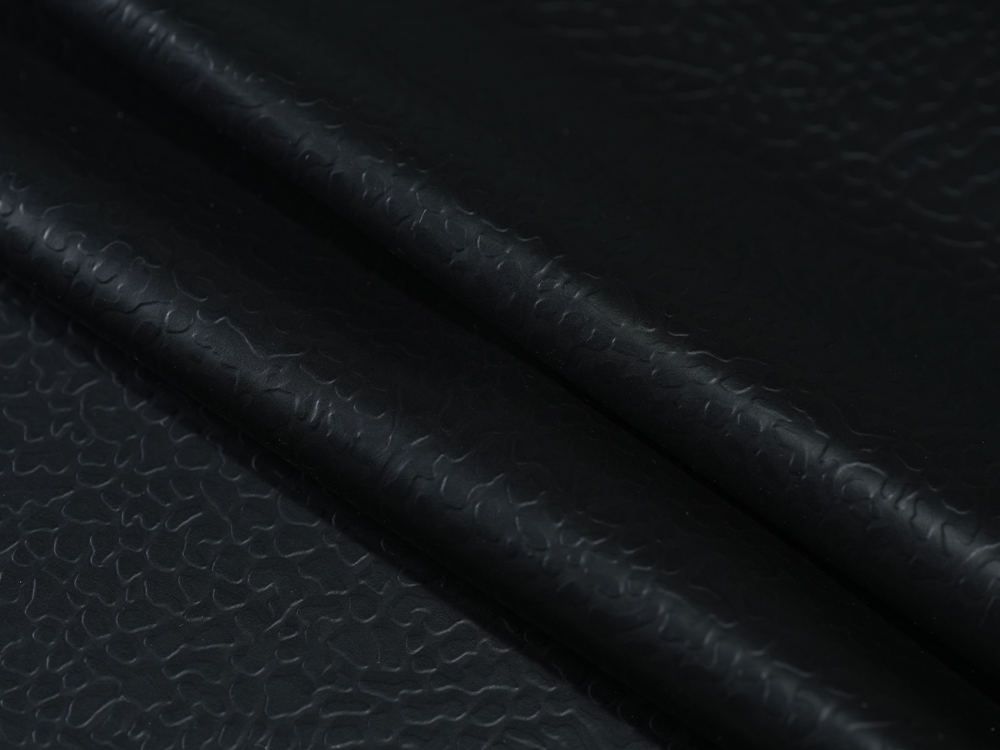

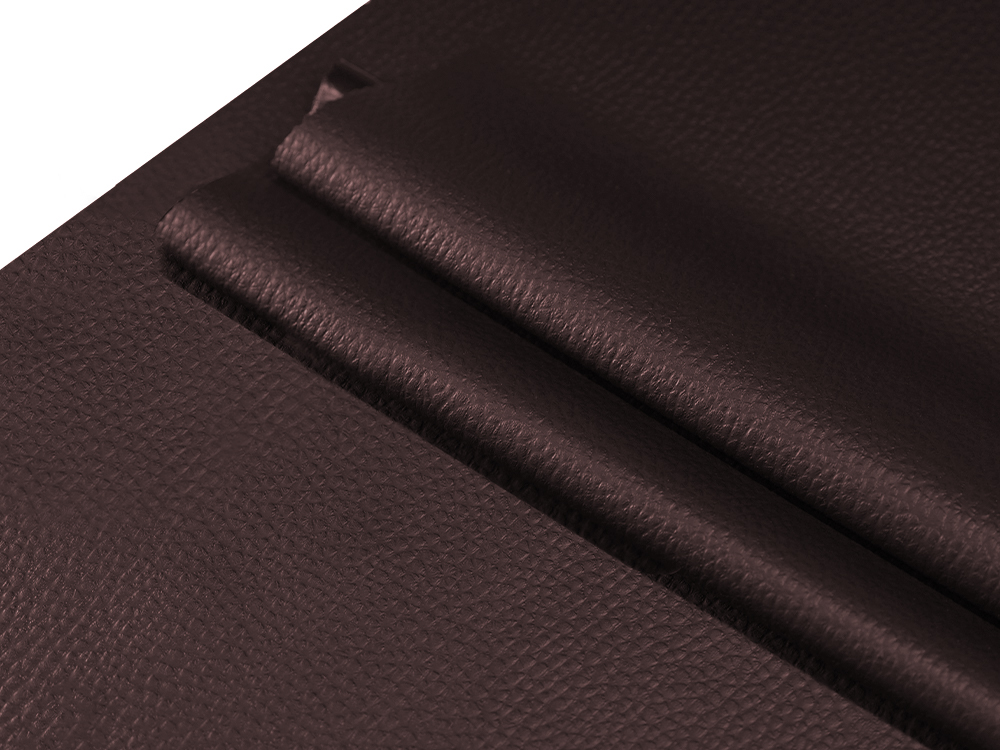

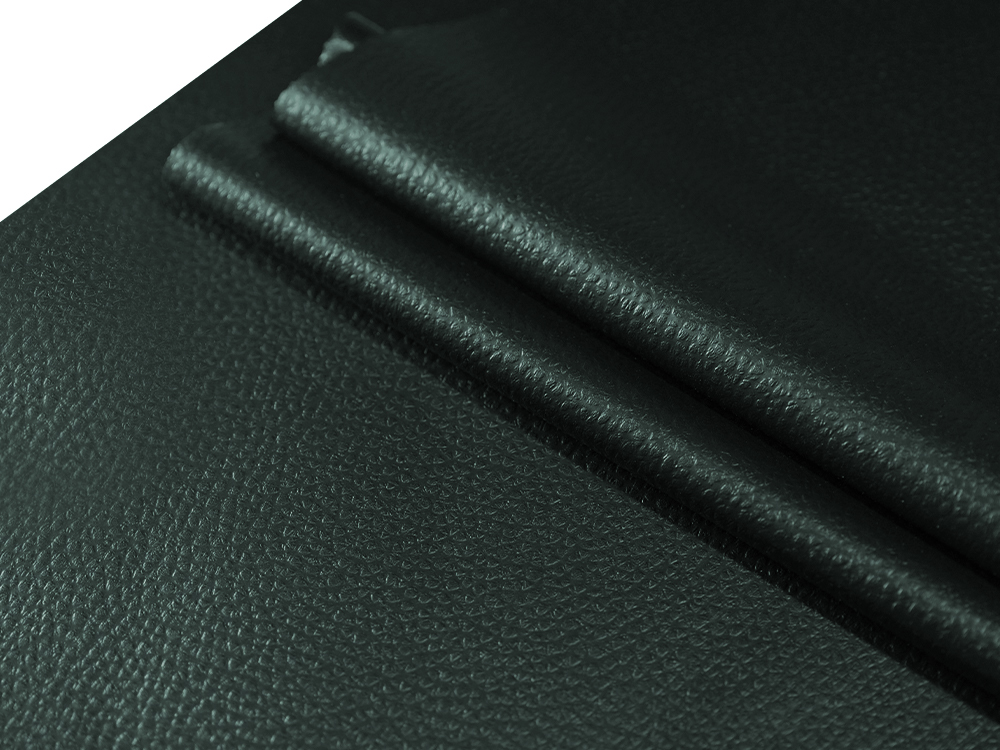

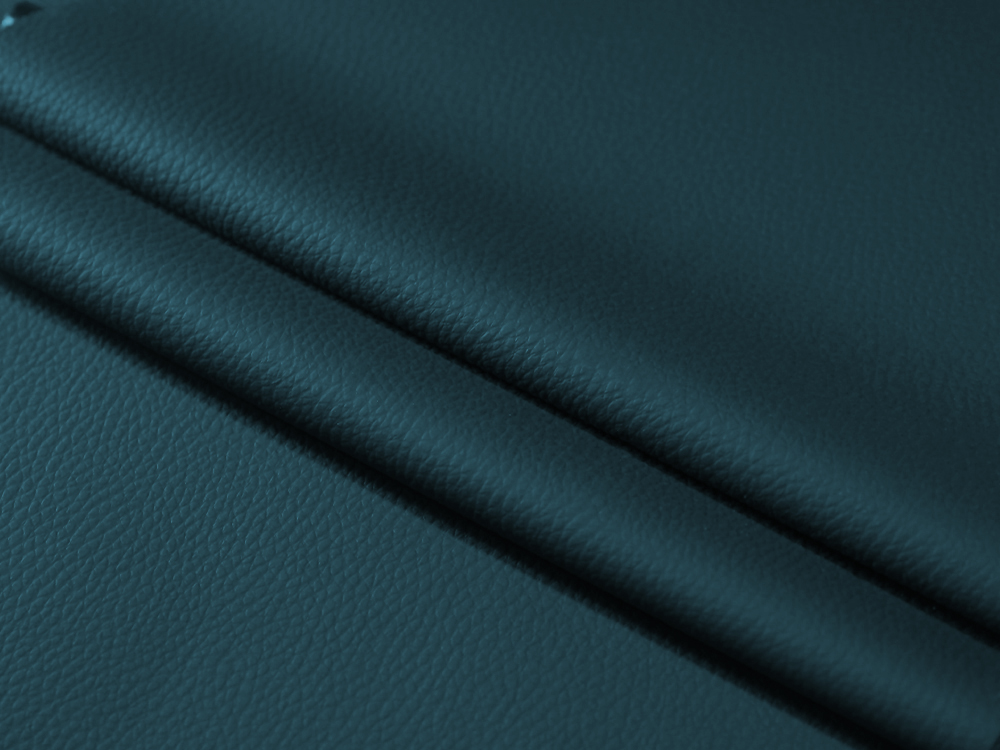

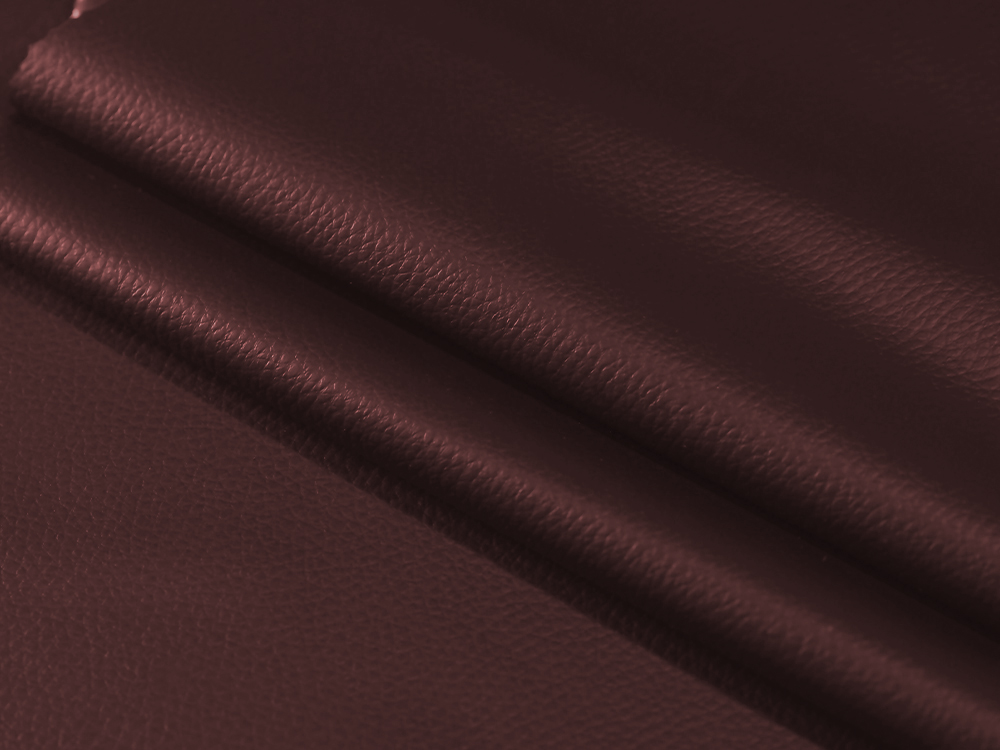

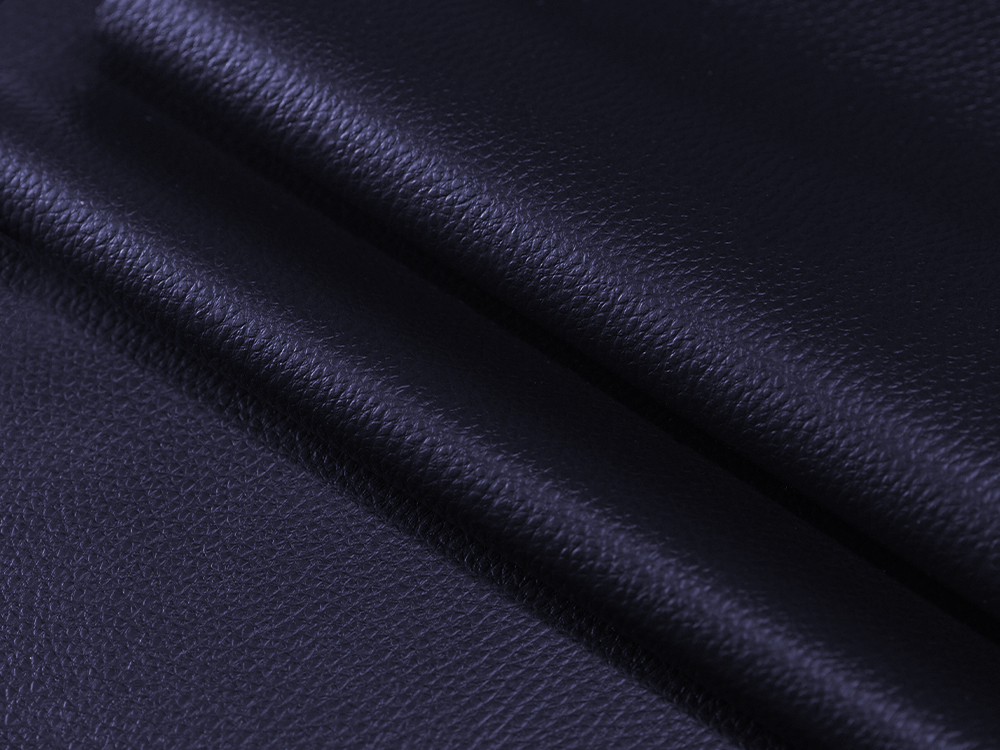

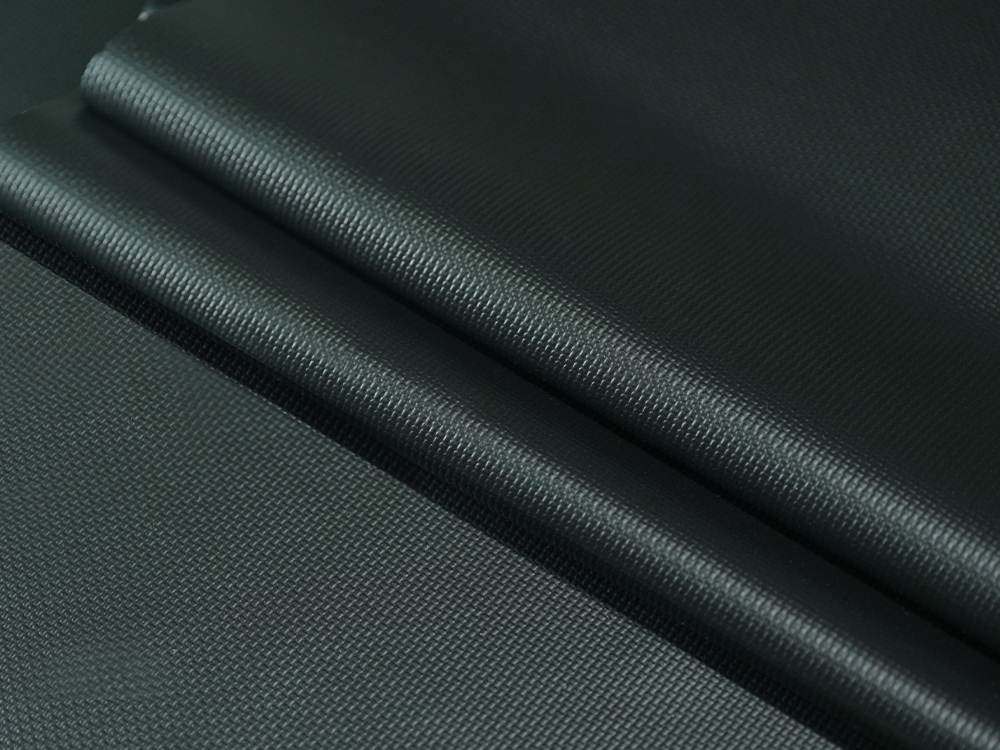

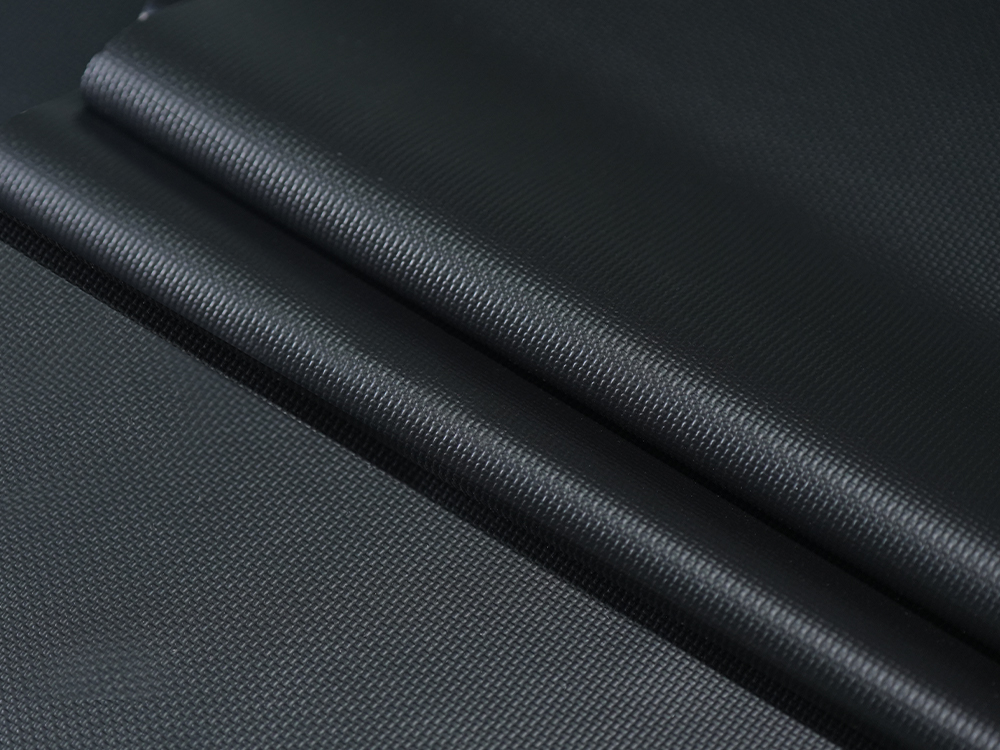

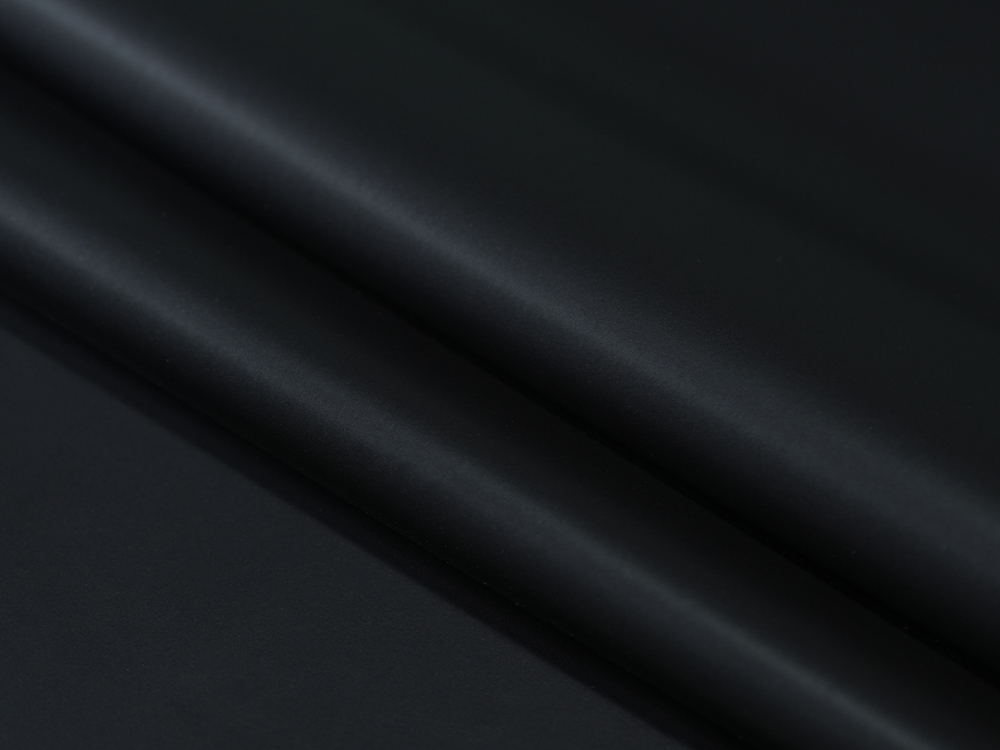

- Surface Finish: Depending on customer requirements, release paper can offer matte, semi-gloss, or glossy finishes, directly influencing the final texture of synthetic luggage leather.

- Mechanical Strength: Sufficient tensile and tear strength ensures the paper can withstand repeated handling during hot pressing or lamination processes without tearing.

- Reusability: High-quality release paper can be reused multiple times, improving cost efficiency and reducing material waste in production.

Manufacturing Advantages of Anhui Honghuan Release Paper

Anhui Honghuan New Material Technology Co., Ltd has developed advanced high-temperature release paper that meets industrial demands for PU and PVC-coated luggage leather. Key manufacturing advantages include:

- Precision Coating: Automated and semi-automated lines enable consistent application of release agents, ensuring uniform surface properties across wide paper rolls.

- Customizable Widths and Specifications: Release paper is available in widths from 1,600 mm to 2,350 mm, accommodating a range of industrial equipment and product sizes.

- Tailored Embossing: Customers can request custom gloss levels and embossing (EMB) designs to achieve desired surface textures for luggage leather.

- Quality Testing: Advanced analytical instruments and pilot coating machines guarantee that every roll meets thermal resistance, surface finish, and release performance standards.

Performance Characteristics under PU Coating

When used in high-temperature PU coating processes, release paper exhibits the following performance characteristics:

- Pattern Fidelity: The embossed or printed patterns on the release paper transfer precisely to the synthetic leather surface without distortion.

- Non-Stick Performance: High-quality release coatings prevent PU resin from adhering to the paper, ensuring smooth release during demolding or peeling.

- Surface Uniformity: Release paper contributes to a uniform gloss and texture, minimizing imperfections such as blisters, wrinkles, or uneven resin distribution.

- Thermal Stability: High-temperature release paper resists curling, shrinking, or warping, even during prolonged exposure to elevated temperatures.

Performance Characteristics under PVC Coating

PVC coatings often involve higher temperatures and longer curing times than PU coatings. For release paper for luggage leather, critical performance indicators include:

- Chemical Resistance: The paper coating must resist reaction with PVC plasticizers, stabilizers, or pigments.

- Heat Tolerance: Resistance to deformation ensures the embossed patterns remain consistent after curing.

- Dimensional Stability: Wide paper rolls maintain their shape during continuous processing, avoiding wrinkles or creases on the leather surface.

- Surface Finish: Release paper can help achieve matte, semi-matte, or glossy finishes, enhancing aesthetic appeal.

Comparison of PU vs. PVC Applications

| Property | PU Coating | PVC Coating | Notes |

|---|---|---|---|

| Typical temperature | 150–200°C | 180–220°C | PVC requires slightly higher heat |

| Release requirements | Smooth, non-stick | High chemical resistance | Both require precise coating |

| Surface finish | Matte to glossy | Matte to semi-gloss | Influences final leather aesthetics |

| Embossing fidelity | High | Very high | PVC may stress paper more |

This comparison highlights the need for specialized high-temperature release paper that can perform reliably in both PU and PVC coating environments.

Selection Guidelines for Manufacturers

When selecting release paper for luggage leather for high-temperature processes, manufacturers should consider:

- Temperature Range Compatibility: Ensure the paper meets or exceeds the maximum processing temperature of PU or PVC coatings.

- Release Agent Quality: Use paper coated with high-performance release agents to prevent sticking or residue.

- Embossing Requirements: Confirm that paper patterns match desired leather textures and maintain fidelity after heat exposure.

- Roll Width and Length: Select dimensions compatible with production lines to minimize downtime.

- Reusability and Cost Efficiency: Evaluate the potential for multiple uses while maintaining consistent performance.

Quality Assurance and Testing

Anhui Honghuan ensures rigorous quality control through multiple testing stages:

- Pilot coating tests simulate real production conditions for PU and PVC applications.

- Analytical instruments measure thermal resistance, tensile strength, and coating uniformity.

- Sampling inspection ensures that pattern transfer and release performance meet client specifications.

These measures guarantee that every roll of release paper for luggage leather maintains high consistency, reducing production defects and operational interruptions.

Operational Efficiency and Logistics

High-temperature release paper contributes not only to product quality but also to production efficiency. Key benefits include:

- Reduced Downtime: Stable paper performance prevents machine stoppages caused by sticking or tearing.

- Consistent Output: Reliable pattern transfer and surface finish minimize rework and scrap.

- Flexible Scheduling: Anhui Honghuan’s production lines can accommodate urgent orders, ensuring timely delivery to meet tight deadlines.

Additionally, the company’s strategic factory locations and experience in transportation logistics ensure safe and prompt delivery, further supporting smooth manufacturing operations.

Environmental and Sustainability Considerations

With growing industry focus on sustainability, manufacturers increasingly prefer release paper for luggage leather that is:

- Made from responsibly sourced base paper and coatings.

- Reusable multiple times to reduce material waste.

- Compatible with low-emission PU and PVC resins, minimizing environmental impact.

By combining durability, reusability, and high-temperature performance, high-quality release paper aligns with both industrial efficiency and environmental responsibility.

Future Trends and Innovations

The demand for high-performance release paper for luggage leather is expected to grow alongside the expansion of synthetic leather applications. Key trends include:

- Enhanced Heat Resistance: Development of papers that withstand even higher temperatures without deformation.

- Custom Texture Capabilities: Advanced embossing techniques to mimic natural leather patterns more closely.

- Eco-Friendly Coatings: Innovative release agents that reduce VOC emissions and chemical residues.

- Smart Production Monitoring: Integration of sensors to monitor coating consistency, paper tension, and temperature in real time.

These innovations aim to support the evolving needs of luggage manufacturers while maintaining production efficiency and product quality.

Conclusion

The performance of release paper for luggage leather under high-temperature PU or PVC coating conditions is critical to achieving superior synthetic leather products. By selecting paper with excellent thermal stability, precise embossing, and reliable release properties, manufacturers can ensure uniform texture, surface quality, and production efficiency. Anhui Honghuan New Material Technology Co., Ltd provides advanced high-temperature release paper solutions, backed by robust R&D, precise production processes, and rapid after-sales support, offering consistent quality and operational reliability for luggage leather applications.

Frequently Asked Questions (FAQs)

Q1: What makes high-temperature release paper different from standard release paper?

A1: High-temperature release paper is designed to withstand elevated PU and PVC coating temperatures without deforming, losing embossing fidelity, or causing sticking issues.

Q2: Can the same release paper be used for both PU and PVC coatings?

A2: Yes, but it must meet the highest temperature and chemical resistance requirements of PVC coatings while maintaining smooth release performance for PU.

Q3: How many times can high-temperature release paper be reused?

A3: Depending on coating conditions and handling, quality release paper can typically be reused multiple cycles without compromising texture or surface finish.

Q4: Are custom embossing patterns available for luggage leather applications?

A4: Yes, tailored EMB designs can be produced to meet specific customer requirements, including matte, semi-gloss, or glossy finishes.

Q5: How does release paper affect production efficiency?

A5: High-quality release paper prevents sticking, maintains pattern fidelity, reduces rework, and minimizes downtime, contributing directly to smoother and more efficient manufacturing operations.

English

English 中文简体

中文简体