Submit feedback

Custom Release Paper for Floor Leather Manufacturers

Industry Knowledge Extension

What is the difference between high-gloss and matte Release Paper for Floor Leather?

Understanding Release Paper for Floor Leather

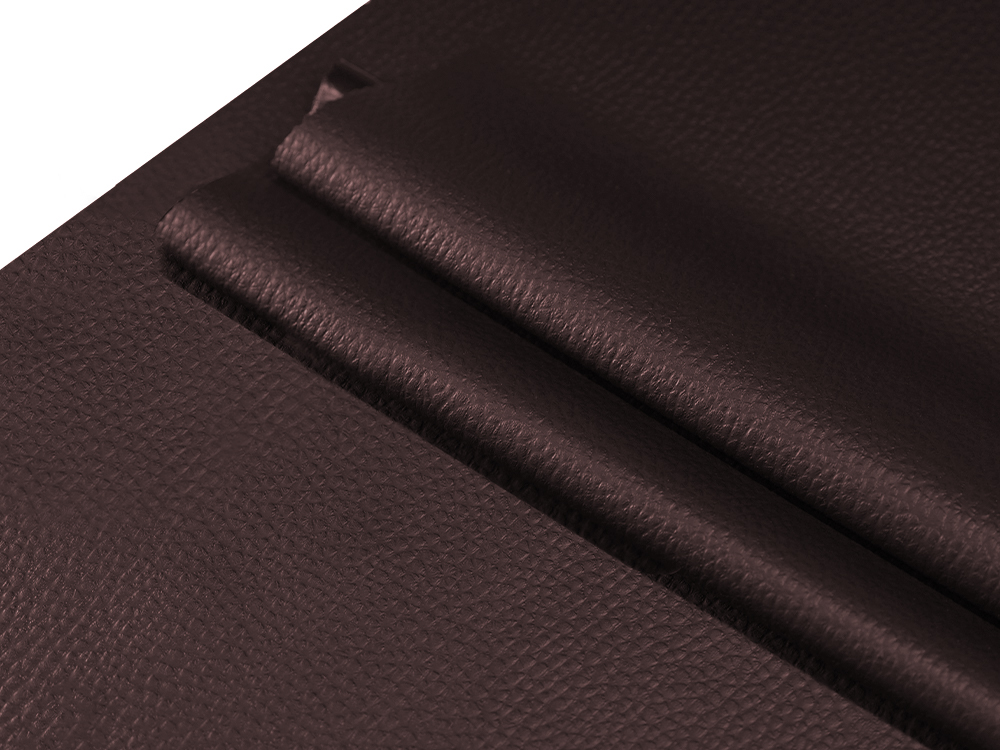

Release paper for floor leather is a critical material used in the production of synthetic flooring products. It acts as a protective layer that ensures smooth release of leather sheets from embossing rollers or molds during manufacturing. By preventing sticking, surface damage, and defects, release paper maintains the quality and consistency of floor leather, which is essential in achieving visually appealing and durable products.

Manufacturers utilize different types of release paper to meet specific production requirements, with high-gloss and matte release paper being the two most widely used variants. The choice between these types can significantly influence the appearance, texture, and performance of the final floor leather product.

What defines high-gloss release paper for floor leather?

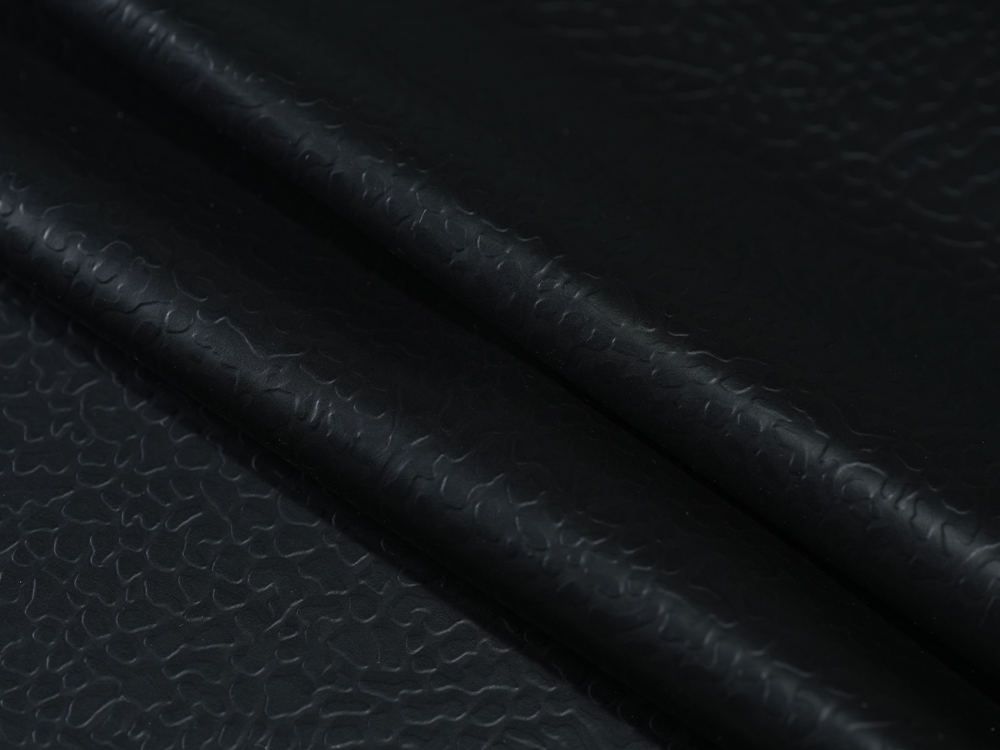

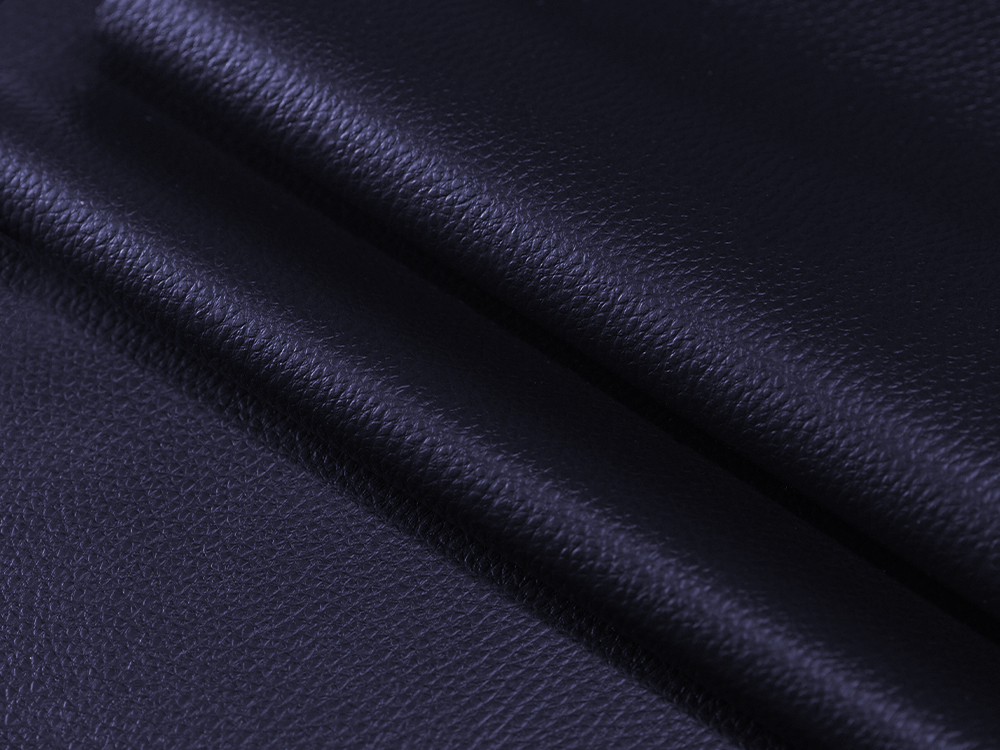

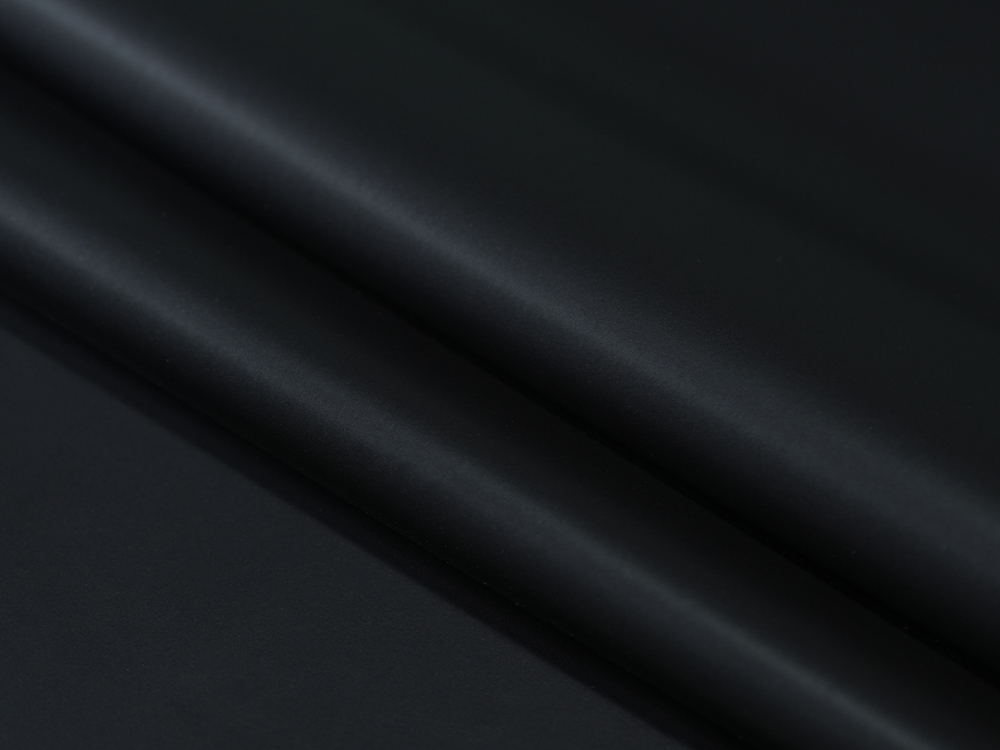

High-gloss release paper is coated with a surface finish that provides maximum reflectivity and smoothness. This type of paper is commonly used when floor leather requires a shiny, polished appearance. The reflective surface of high-gloss release paper ensures that embossing patterns are transferred accurately and consistently while minimizing surface irregularities.

Key characteristics of high-gloss release paper include:

- Smooth, reflective surface

- Excellent heat resistance for high-temperature embossing

- Precise pattern transfer with minimal surface defects

- Enhanced ability to reproduce intricate textures and designs

High-gloss release paper is preferred in applications where visual appeal is a priority. It is widely used in premium flooring products, where the surface must maintain a polished, attractive look over time.

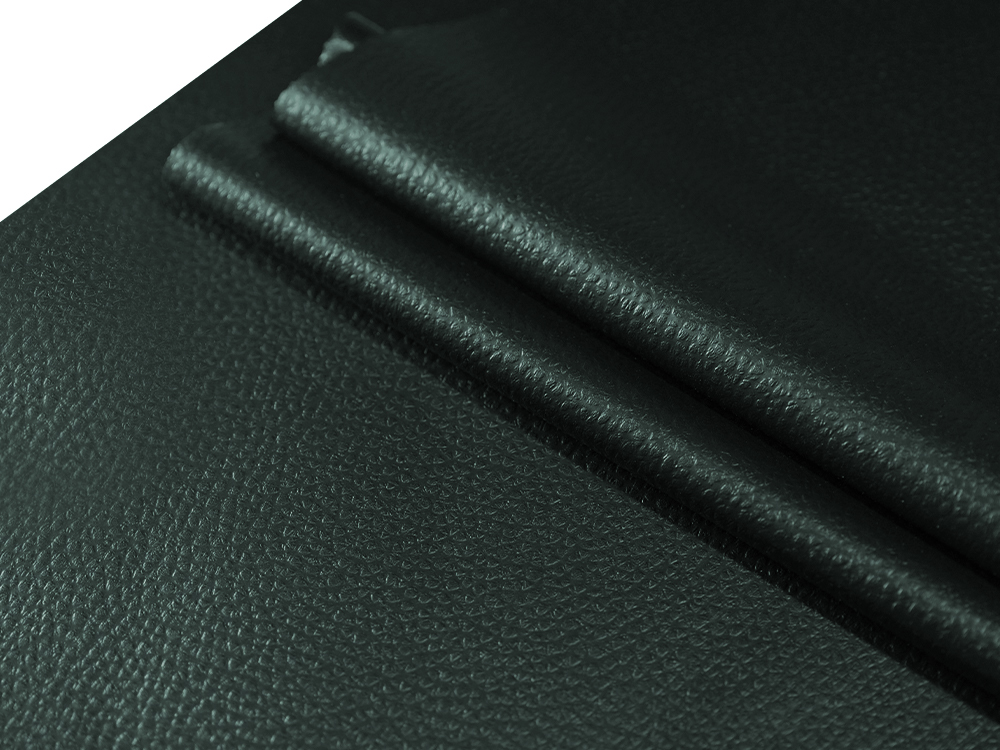

What defines matte release paper for floor leather?

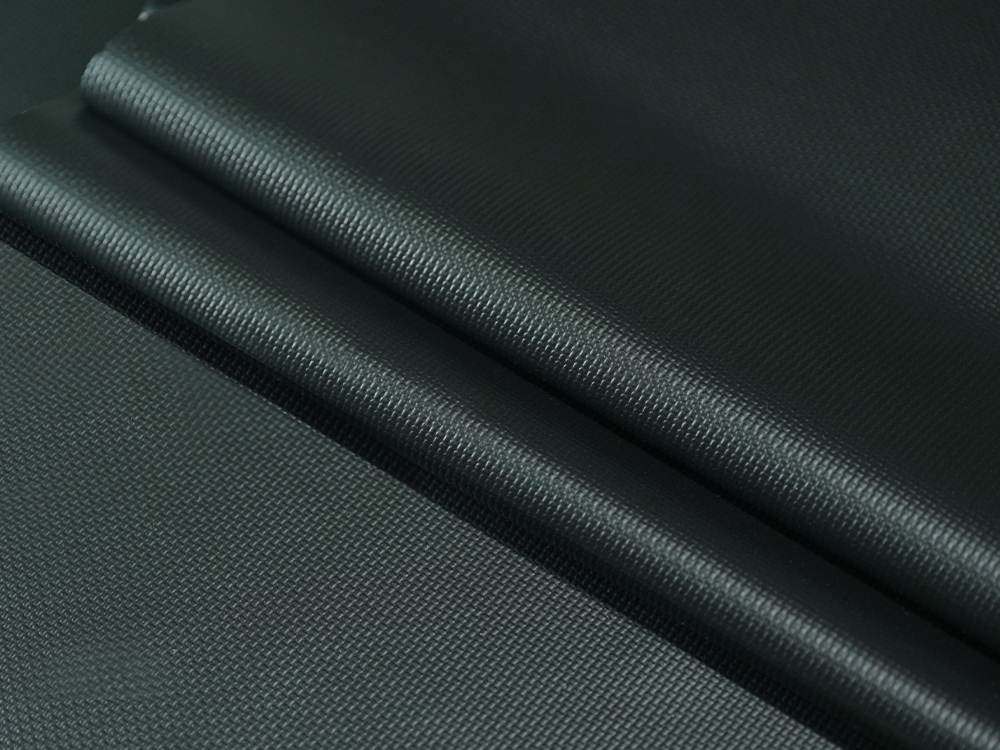

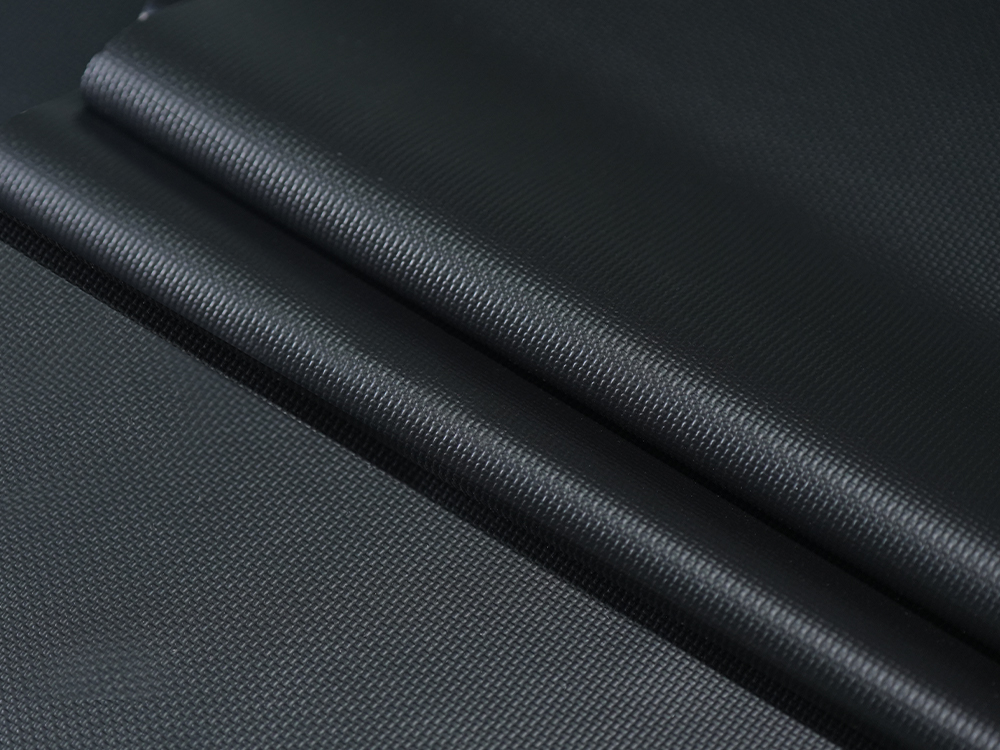

Matte release paper, in contrast, provides a subtle, low-reflective finish. This type of paper is ideal when a natural, understated texture is desired in the final floor leather product. Matte release paper absorbs light differently than high-gloss paper, which can give the leather a softer, more tactile surface.

Key characteristics of matte release paper include:

- Low reflectivity for a natural look

- Excellent heat resistance, similar to high-gloss paper

- Smooth but less reflective surface for subtle texture transfer

- Suitable for anti-slip or functional floor leather applications

Matte release paper is often chosen for commercial or industrial flooring where practicality and safety, such as slip resistance, are as important as aesthetics.

Technical differences between high-gloss and matte release paper

The differences between high-gloss and matte release paper go beyond appearance. The surface coating, texture, and heat-resistance properties determine how each type interacts with floor leather during production. Below is a concise comparison:

| Gloss Level | Surface Texture | Pattern Transfer | Typical Application |

|---|---|---|---|

| High-Gloss | Smooth, reflective | Precise, shiny | Premium flooring, decorative panels |

| Matte | Low-reflective, soft | Subtle, natural | Commercial flooring, anti-slip surfaces |

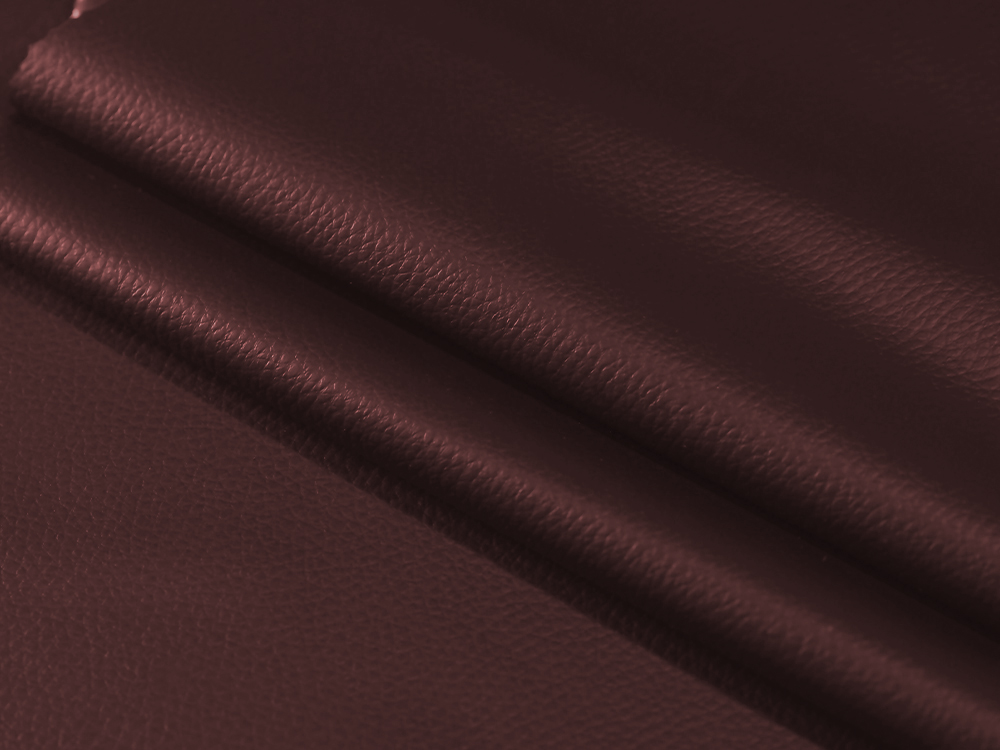

High-gloss paper often uses a denser coating formulation, which allows for higher temperature tolerance and better definition of embossed patterns. Matte paper, while also heat-resistant, prioritizes subtle texture reproduction, which can reduce glare and enhance surface grip.

How release paper influences floor leather quality

The choice of release paper has a direct impact on the surface quality, durability, and aesthetic appeal of floor leather. Incorrect selection can result in:

- Surface imperfections such as sticking or tearing

- Inconsistent embossing patterns

- Reduced gloss or undesired reflections

- Compromised anti-slip properties

By selecting the appropriate type of release paper for floor leather, manufacturers can ensure that the final product meets both aesthetic and functional requirements.

Manufacturing considerations

Anhui Honghuan New Material Technology Co., Ltd, a manufacturer of high-temperature release paper for synthetic leather, integrates advanced R&D, production, and quality control processes. With automated and semi-automated production lines, the company produces release paper for floor leather with consistent coating quality and adjustable gloss levels to suit diverse customer requirements.

The company’s high-temperature-resistant release paper ensures reliable embossing performance for both high-gloss and matte finishes, enabling accurate replication of patterns and textures. Advanced pilot coating machines and analytical instruments maintain product stability and uniformity, reducing the risk of defects during production.

Choosing the right release paper

When deciding between high-gloss and matte release paper for floor leather, manufacturers should consider:

- End-product aesthetics: Shiny floors require high-gloss paper, while matte floors or functional surfaces benefit from low-reflective paper.

- Production temperature: High-temperature embossing demands release paper with adequate heat resistance.

- Pattern complexity: High-gloss paper enhances the definition of intricate patterns; matte paper provides more subtle texture reproduction.

- Slip resistance: Matte release paper can improve surface grip for safety-critical applications.

Customized solutions from professional manufacturers allow clients to select the appropriate paper based on specific design or functional needs.

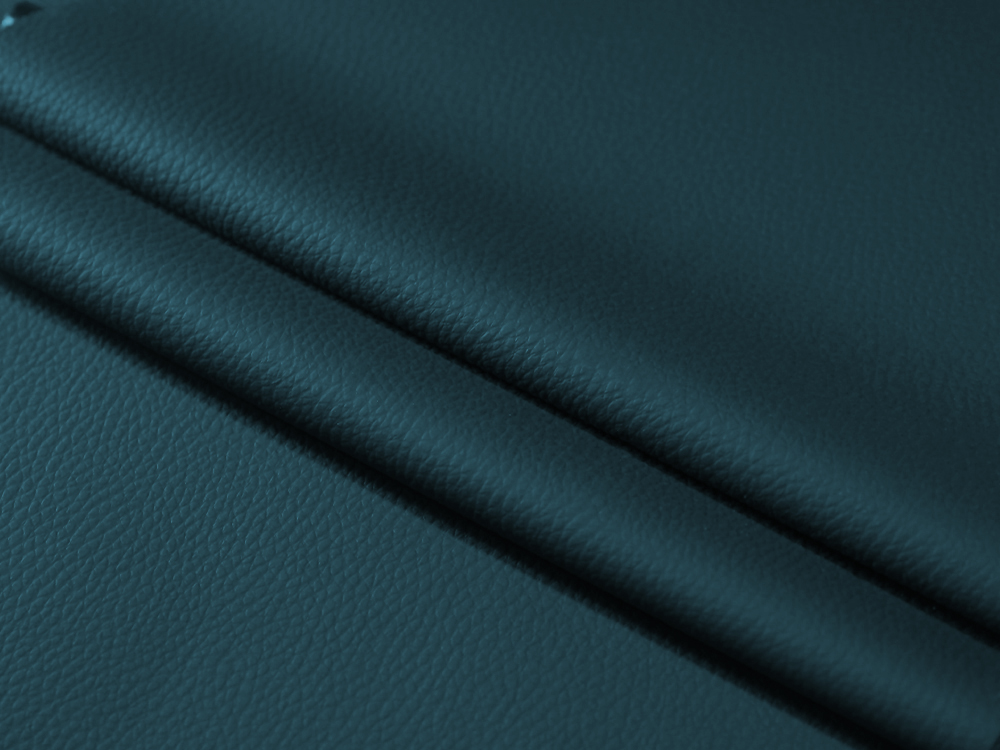

Gloss and texture performance

The gloss of release paper for floor leather influences how light interacts with the final product. High-gloss paper reflects light uniformly, making embossed patterns more pronounced. Matte paper scatters light, reducing reflections and giving the leather a more natural appearance. Both types provide heat stability and durability but differ in tactile feel and visual impact.

Advanced coating techniques, such as PE coating or specialized chemical treatments, are applied to enhance the release performance and surface consistency. These coatings also protect the base paper and allow for repeated use in high-volume manufacturing.

Production flexibility and specifications

Professional manufacturers, like Anhui Honghuan, offer release paper for floor leather in widths ranging from 1,600 mm to 2,350 mm, with adjustable specifications to meet diverse production requirements. Small-scale orders are accommodated with flexible minimum order quantities, ensuring that manufacturers of all sizes can access high-quality release paper.

Customized embossed (EMB) designs and varying gloss levels are supported, providing flexibility in product development. OEM and ODM services further allow clients to obtain tailored solutions for unique floor leather applications.

Quality control and testing

Maintaining high quality is critical for both high-gloss and matte release paper for floor leather. Quality assurance measures include:

- Coating thickness uniformity tests

- Heat-resistance performance checks

- Surface smoothness and gloss measurement

- Pattern transfer accuracy evaluations

These tests ensure that every roll of release paper meets stringent performance standards and delivers consistent results in the manufacturing process.

Environmental and operational considerations

Sustainable production practices are increasingly important in floor leather manufacturing. Professional release paper providers focus on stable supply chains, reliable base paper sources, and consistent raw material quality. Proper storage and handling of release paper also maintain its performance characteristics, preventing issues such as moisture absorption, surface damage, or contamination.

Advantages of working with specialized manufacturers

Collaborating with an experienced manufacturer offers several benefits:

- Reliable product quality: Advanced equipment and skilled R&D teams ensure consistent results.

- Technical support: Rapid-response service assists in selecting the correct paper type.

- Production efficiency: Automated and semi-automated lines support large-scale orders without compromising quality.

- Customization: OEM and ODM options allow tailored gloss levels, EMB designs, and roll sizes.

By leveraging these advantages, flooring producers can improve efficiency, reduce defects, and meet specific design requirements.

Key takeaways

Choosing the correct type of release paper for floor leather is essential for achieving the desired appearance, texture, and functional performance.

- High-gloss release paper is ideal for polished, visually striking surfaces with precise pattern definition.

- Matte release paper offers natural texture, subtle reflections, and enhanced slip resistance for commercial or safety-focused applications.

A professional manufacturer ensures that each type of release paper provides reliable, consistent performance, supporting high-quality floor leather production across different industrial applications.

FAQs

Q1: Can high-gloss and matte release paper be used interchangeably?

A: While technically possible, using the wrong type can compromise the surface appearance, gloss, and functional properties of floor leather. Selection should match the intended end-product requirements.

Q2: What widths are available for release paper for floor leather?

A: Common widths range from 1,600 mm to 2,350 mm, with customizable options to suit specific production needs.

Q3: How does release paper impact embossing quality?

A: Release paper determines how accurately textures and patterns are transferred to floor leather. Coating quality, smoothness, and gloss level all influence embossing performance.

Q4: Is it possible to customize gloss levels and embossed designs?

A: Yes, manufacturers provide tailored solutions, including customized gloss levels, EMB patterns, and OEM/ODM options to meet diverse client requirements.

Q5: How is the heat resistance of release paper ensured?

A: Through advanced coating techniques and precise quality control tests, the release paper maintains stability under high-temperature embossing conditions.

English

English 中文简体

中文简体