Submit feedback

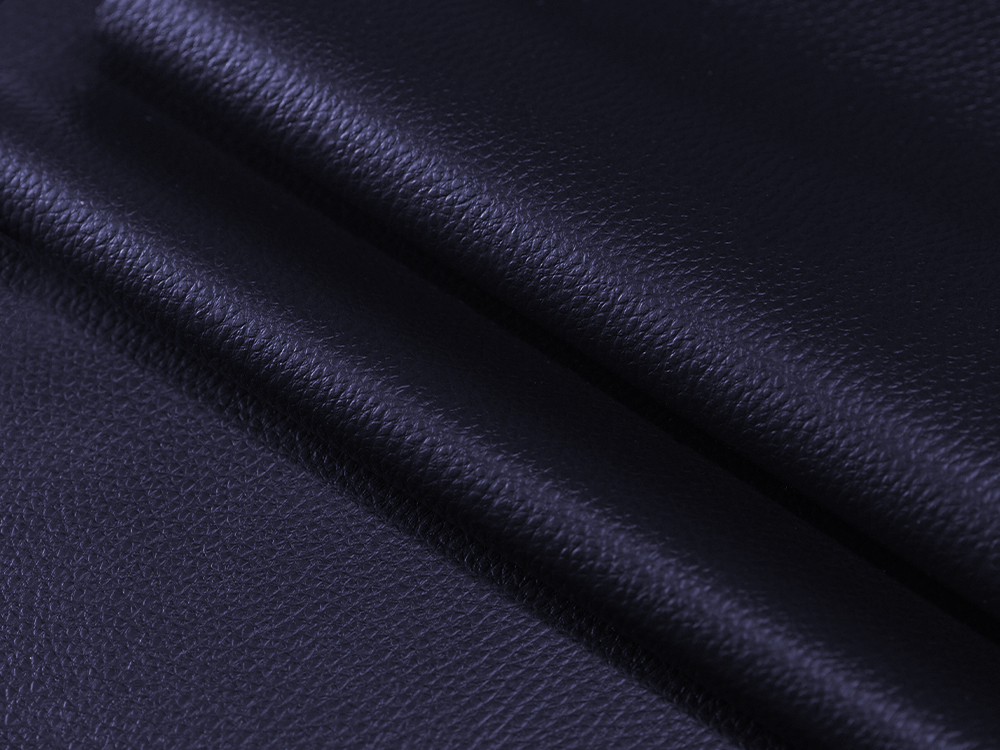

Custom Release Paper for Car Leather Manufacturers

Industry Knowledge Extension

How does release paper for car leather support anti-scratch and anti-fingerprint surface effects?

Release paper for car leather plays a critical role in the automotive leather industry, ensuring that high-quality leather surfaces maintain their visual appeal and durability. Modern vehicles demand leather interiors that not only provide comfort but also retain their pristine appearance over time. Scratches, fingerprints, and other surface imperfections can compromise the perceived value of automotive interiors, making anti-scratch and anti-fingerprint solutions essential. Among various methods to achieve these effects, release paper for car leather stands out as a reliable and efficient tool used throughout the leather production process.

The role of release paper in car leather manufacturing

In leather production, release paper serves as an intermediary layer between the leather and embossing or coating systems. Its primary functions include preventing sticking, supporting consistent texture replication, and ensuring the leather surface remains defect-free during heat and pressure processes.

Key functions of release paper for car leather include:

- Protecting the leather surface from mechanical damage.

- Ensuring uniform texture application, which reduces the likelihood of fingerprints or surface distortions.

- Supporting high-temperature operations without compromising surface quality.

By providing a protective barrier during processing, release paper for car leather reduces direct contact with tooling surfaces, thereby significantly decreasing the chances of scratches and fingerprints forming on the final product.

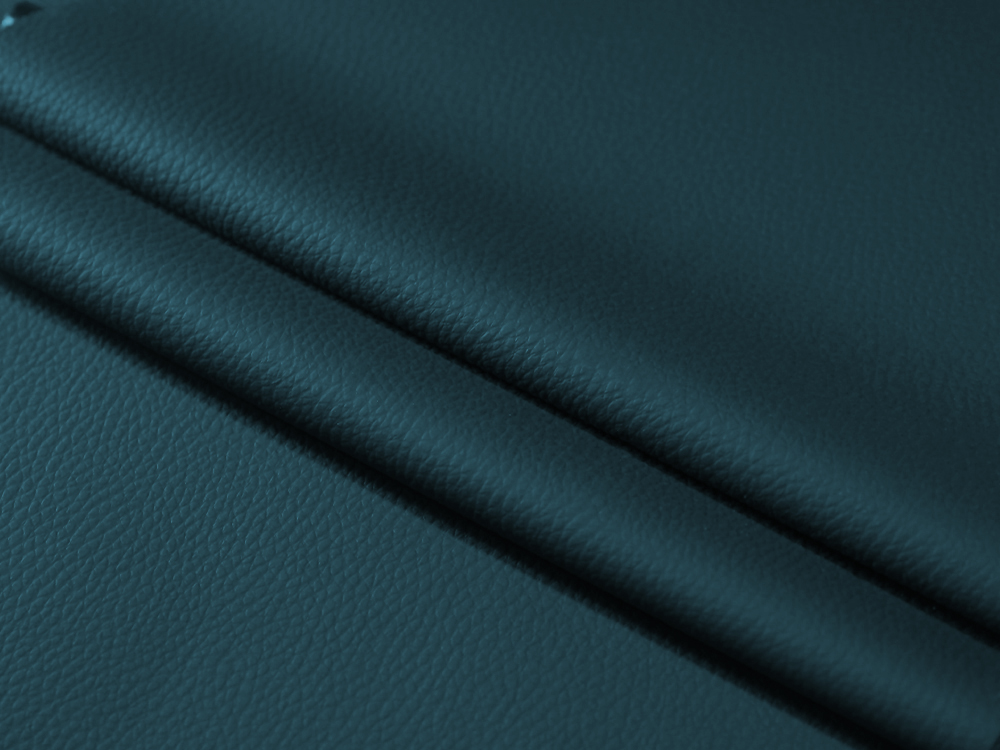

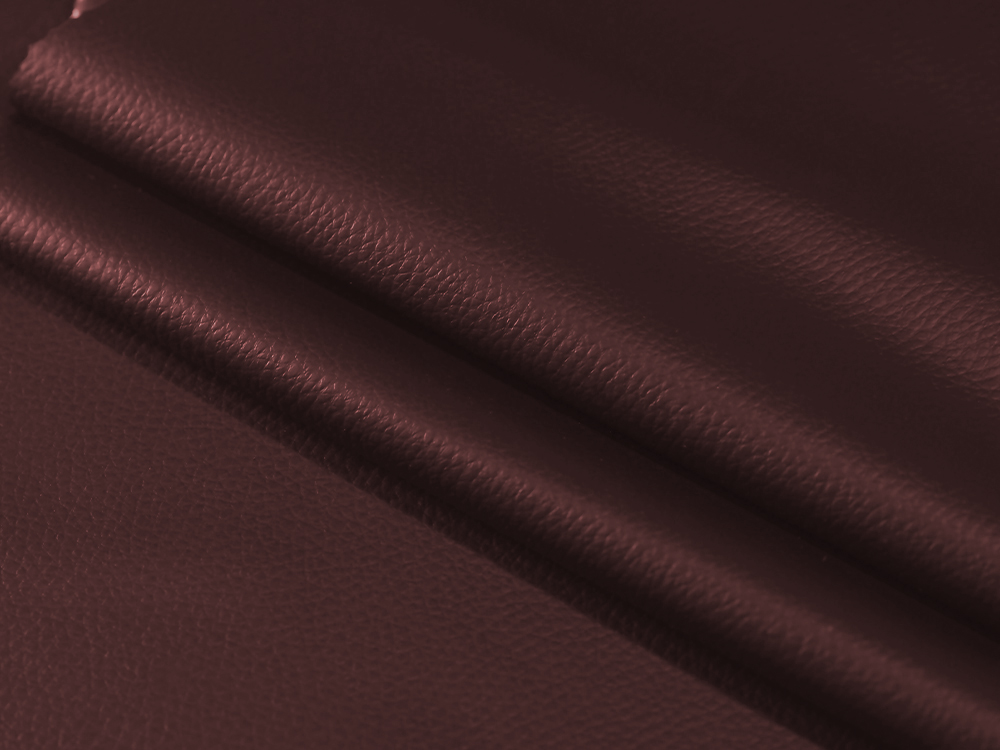

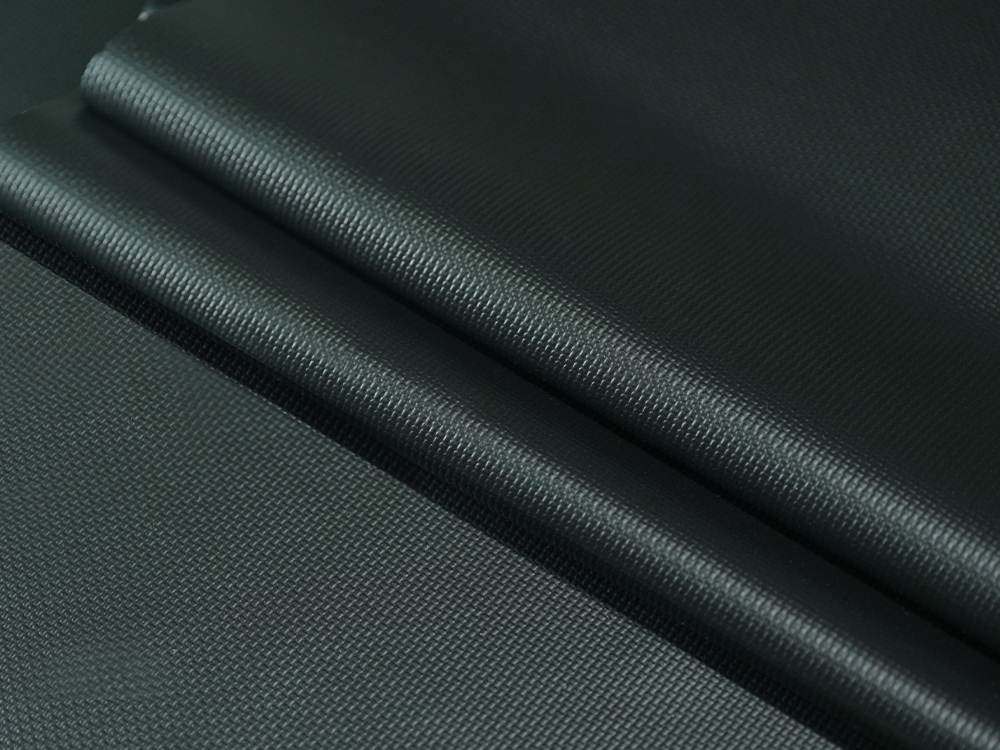

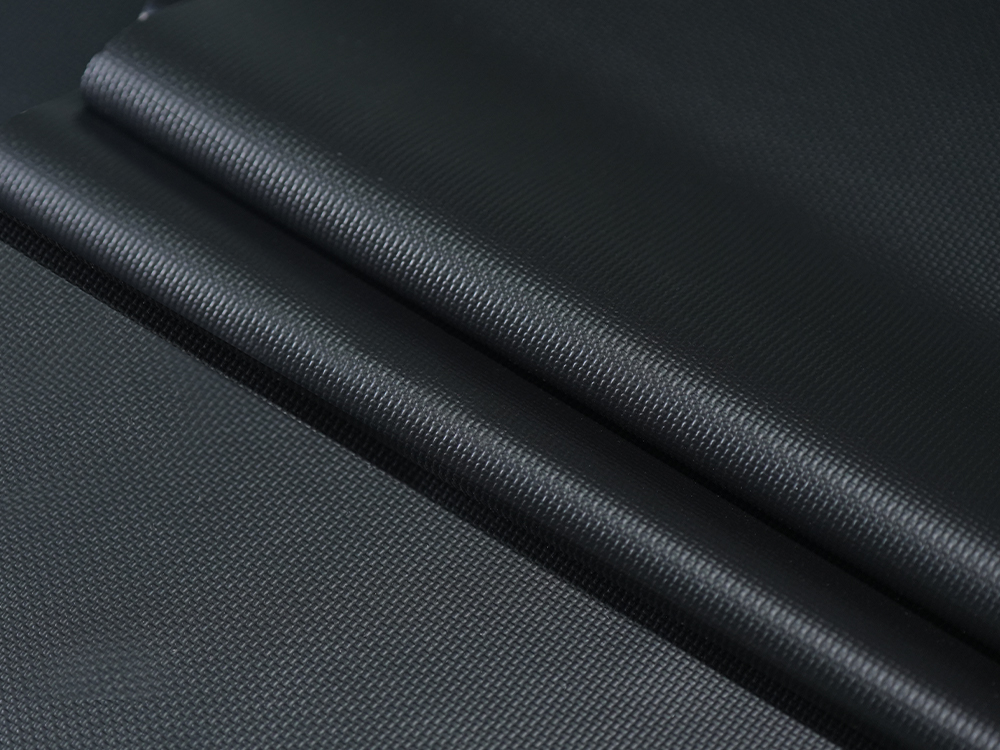

Material composition and surface properties

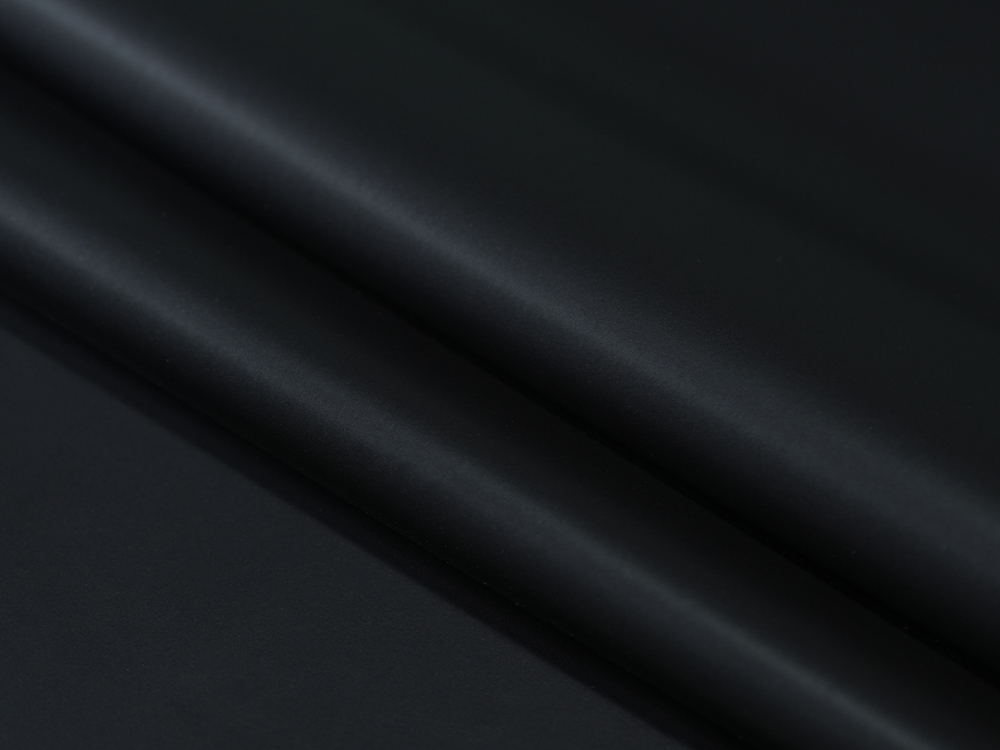

The effectiveness of release paper for car leather in preventing scratches and fingerprints is largely determined by its material composition and surface design. High-quality release papers often feature:

- Silicone-coated surfaces: Silicone provides excellent non-stick properties, allowing leather to separate cleanly from the paper without leaving marks. This coating also reduces friction, preventing micro-scratches during handling.

- High-temperature resistance: Automotive leather processing often involves temperatures exceeding 120°C. Release papers engineered to withstand such heat maintain their structural integrity and surface smoothness, which is critical for avoiding unwanted impressions on leather.

- Controlled surface roughness: By carefully designing the texture of the release paper, manufacturers can produce leather with an optimized grain pattern that naturally resists fingerprints while maintaining aesthetic appeal.

Anhui Honghuan New Material Technology Co., Ltd, a leading manufacturer of high-temperature release paper for synthetic leather, provides a range of release papers specifically engineered to meet these stringent requirements. Their products ensure reliable anti-scratch and anti-fingerprint effects, even under intensive production cycles.

Anti-scratch performance

Release paper for car leather contributes to scratch resistance in several ways:

- Mechanical barrier: The release paper prevents direct contact between the leather and production equipment, which is a common source of scratches.

- Consistent embossing: For textured leather, the release paper ensures that embossing rollers or plates distribute pressure evenly. Uneven pressure can cause micro-scratches or surface inconsistencies.

- Protective coatings: Silicone and other advanced coatings on release paper reduce surface friction, further minimizing the risk of scratches during handling, stacking, or transportation.

Table: Comparison of release paper properties influencing scratch resistance

| Type of Release Paper | Coating Material | Surface Texture | Scratch Protection Effect |

|---|---|---|---|

| Silicone Coated High-Temp | Silicone | Smooth | Excellent |

| PE-Coated Standard | PE | Slightly Textured | Moderate |

| Patterned Specialty Paper | Silicone/PE | Customized Grain | High |

The table highlights how material selection and surface design directly impact scratch resistance. Automotive leather manufacturers often select release paper for car leather based on the desired balance between embossing fidelity and scratch prevention.

Anti-fingerprint properties

Fingerprints are primarily caused by natural oils and moisture transferring from hands to the leather surface. During manufacturing, improper handling or inadequate surface protection can leave permanent marks. Release paper for car leather addresses this problem through several mechanisms:

- Non-stick surface: Silicone coatings and other advanced finishes prevent the transfer of oils or residues from the release paper itself to the leather.

- Uniform pressure distribution: When leather is pressed or embossed, release paper ensures consistent pressure, reducing the formation of uneven areas where fingerprints might easily imprint.

- Surface smoothness: Smooth release paper minimizes micro-indentations or textural variations on the leather, which are often focal points for fingerprints.

By controlling these variables, release paper for car leather ensures that automotive leather maintains a pristine surface throughout the production cycle.

Manufacturing considerations

To achieve optimal anti-scratch and anti-fingerprint performance, the production of release paper involves strict process control and advanced technology:

- High-precision coating systems: Uniform silicone or PE coatings are applied to maintain consistent surface characteristics.

- Automated production lines: Automated and semi-automated processes reduce the risk of inconsistencies that can compromise leather surface quality.

- Quality testing: Analytical instruments and pilot coating machines are used to test the release paper’s adhesion, temperature resistance, and surface smoothness.

Anhui Honghuan’s factories in Quanjiao and Qiandeng are equipped with advanced testing and production equipment, enabling precise control over release paper properties. This ensures every sheet of release paper for car leather meets strict industry standards.

Applications in automotive leather

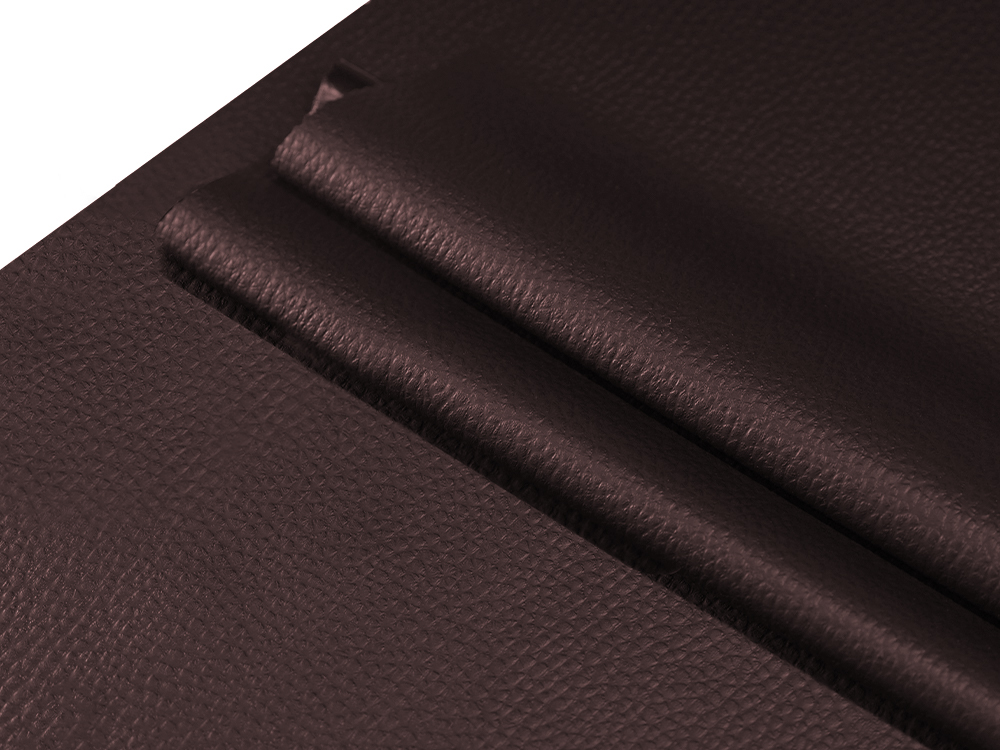

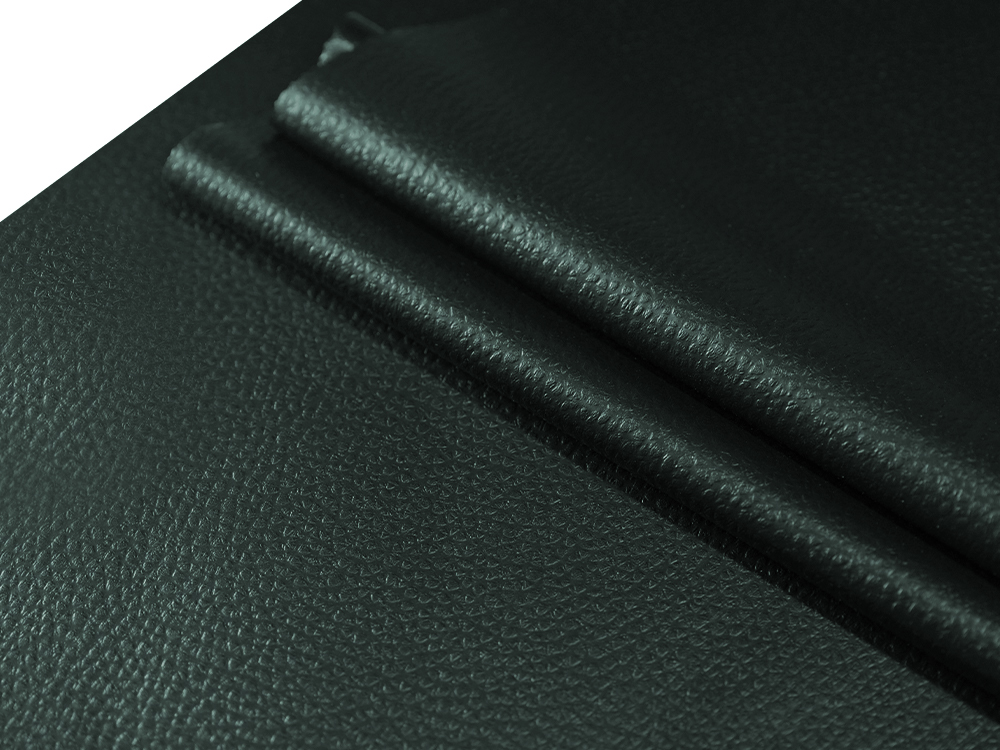

Release paper for car leather is widely applied in the production of:

- Car seats

- Dashboard and door panel trims

- Steering wheel covers

- Luxury interior accents

In each application, the release paper serves as a protective and performance-enhancing intermediary. For example, in high-end leather seating, the combination of embossing and coating processes can easily produce scratches or fingerprints if release paper is substandard. By using high-quality release paper, manufacturers ensure that the final product meets customer expectations for appearance and tactile performance.

Advantages for manufacturers

Using specialized release paper for car leather offers several benefits:

- Improved production efficiency: Reduced defects mean less rework and scrap.

- Enhanced product quality: Consistent surface textures and minimal blemishes improve market appeal.

- Customizability: Width, gloss, and embossing compatibility can be tailored to specific automotive leather types.

- After-sales support: Technical expertise from the manufacturer helps resolve production challenges quickly.

Tailored solutions and OEM/ODM support

Many manufacturers, such as Anhui Honghuan New Material Technology Co., Ltd, offer customized release paper solutions to address unique requirements in automotive leather production. Tailored development allows for adjustments in:

- Gloss levels

- EMB patterns

- Heat resistance thresholds

OEM and ODM services ensure that clients can access release paper for car leather optimized for their production lines, enhancing both efficiency and final product quality.

Future trends

The automotive industry increasingly demands leather surfaces that resist scratches, fingerprints, and other defects while maintaining environmental and sustainability standards. Future developments in release paper for car leather may include:

- Improved eco-friendly coating materials

- Advanced micro-textured surfaces to reduce fingerprints

- High-temperature release papers compatible with next-generation synthetic leather

Such innovations will allow automotive manufacturers to produce high-quality interiors with less manual intervention and lower defect rates.

Conclusion

Release paper for car leather is a vital component in the production of high-quality automotive leather surfaces. By combining non-stick coatings, high-temperature resistance, and controlled surface properties, release paper ensures that leather products resist scratches and fingerprints. Manufacturers benefit from improved efficiency, reduced defects, and enhanced customer satisfaction. Companies like Anhui Honghuan New Material Technology Co., Ltd provide specialized solutions, advanced testing, and tailored services, making them a reliable partner for the automotive leather industry.

FAQs

Q1: What types of coatings are used in release paper for car leather?

A1: Common coatings include silicone, PE, and specialized high-temperature coatings, each offering non-stick properties and protection against scratches.

Q2: How does release paper prevent fingerprints on leather?

A2: Smooth surfaces and non-stick coatings minimize direct contact and uneven pressure, reducing the likelihood of fingerprint formation.

Q3: Can release paper for car leather be customized?

A3: Yes, specifications such as width, gloss, surface pattern, and heat resistance can be tailored to meet specific production requirements.

Q4: What production support services are available from manufacturers?

A4: OEM/ODM services, technical consultation, rapid-response after-sales support, and flexible scheduling are commonly offered.

Q5: What are the benefits of using high-temperature release paper?

A5: High-temperature release paper maintains integrity under heat and pressure, ensuring consistent embossing and surface quality while reducing scratches and fingerprints.

English

English 中文简体

中文简体