Submit feedback

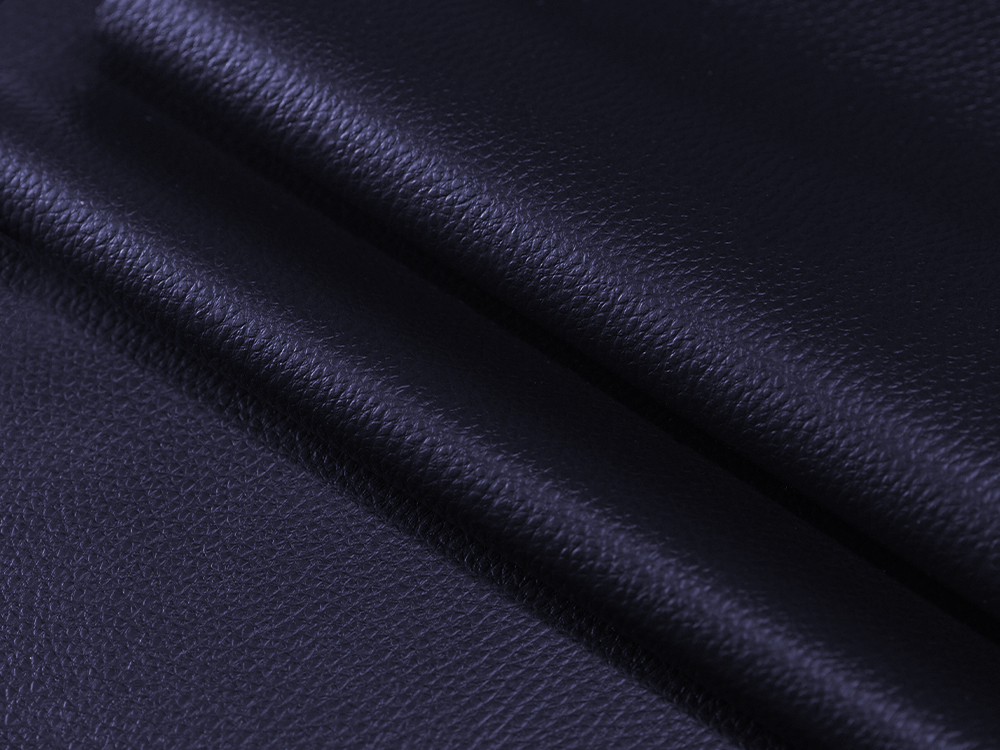

Custom Synthetic Leather Release Paper Manufacturers

Industry Knowledge Extension

What Are the Key Differences Between Various Types of Leather Release Paper?

Introduction

Leather Release Paper plays a crucial role in the leather processing and manufacturing industry by providing a reliable non-stick surface during production. Different types of leather release paper vary in terms of material, coating, heat resistance, and application suitability. Understanding these differences can help manufacturers select the right paper for their specific processes, ensuring quality and efficiency.

Types of Leather Release Paper

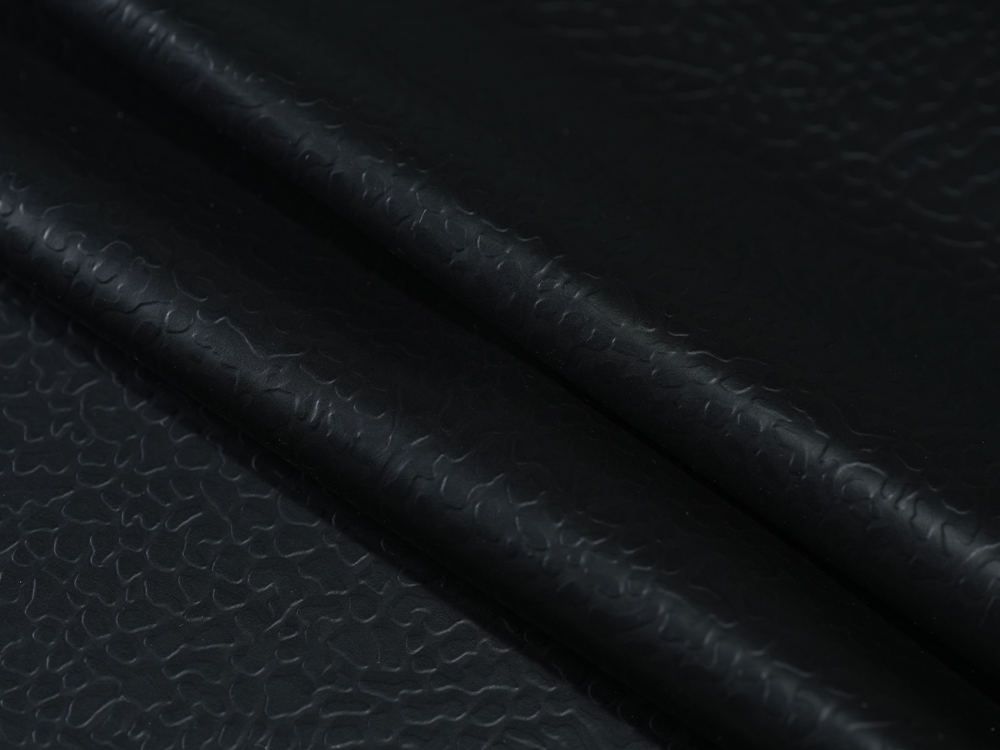

- Silicone Coated Release Paper: This is the most common type, featuring a silicone layer that provides excellent non-stick performance. It is suitable for general leather embossing and laminating applications.

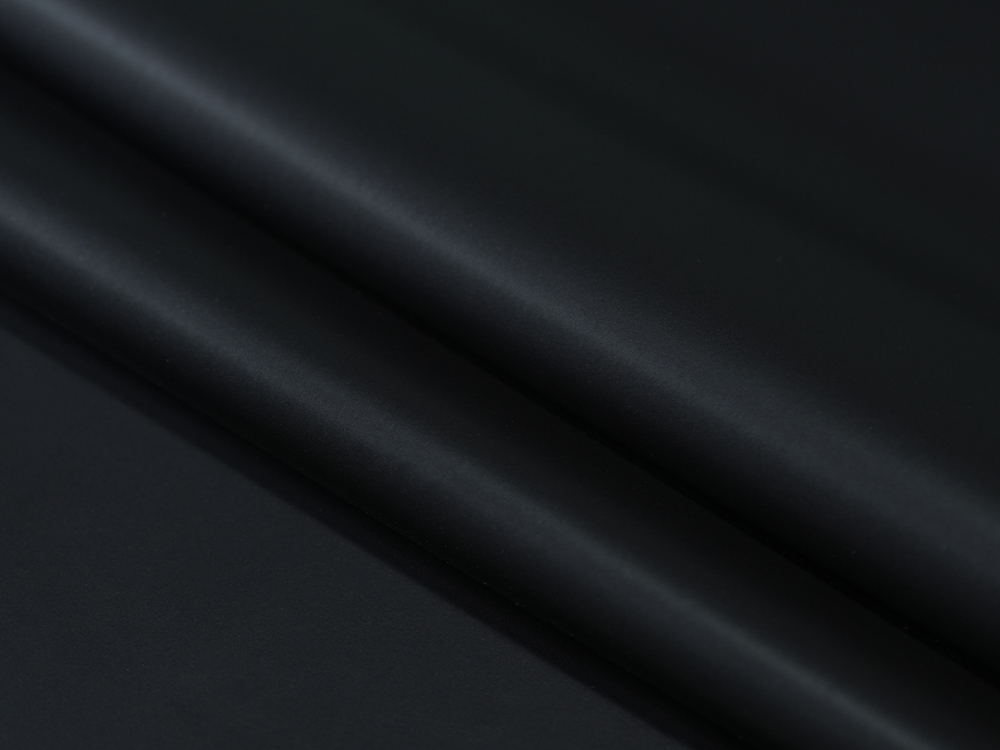

- High-Temperature Resistant Release Paper: Developed for applications requiring exposure to high heat, such as hot stamping or high-temperature laminating. Anhui Honghuan New Material Technology Co., Ltd. successfully developed this type in 2019, ensuring durability and consistent performance.

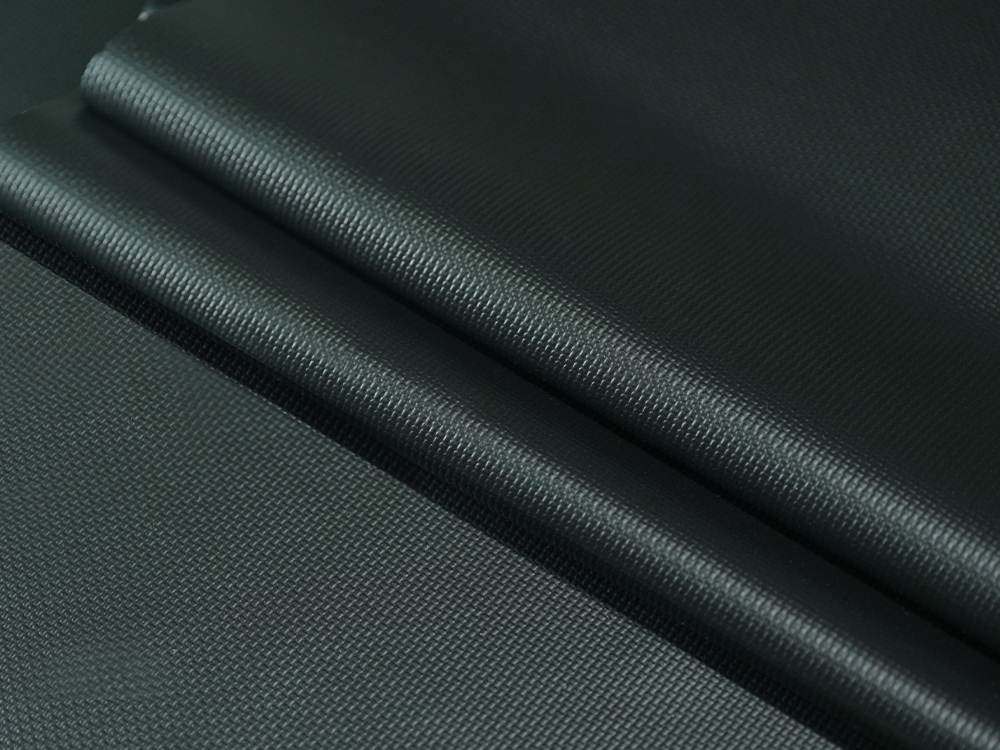

- PE-Coated Leather Release Paper: Coated with polyethylene, this paper offers strong moisture resistance and is ideal for processes where humidity or wet conditions are a concern.

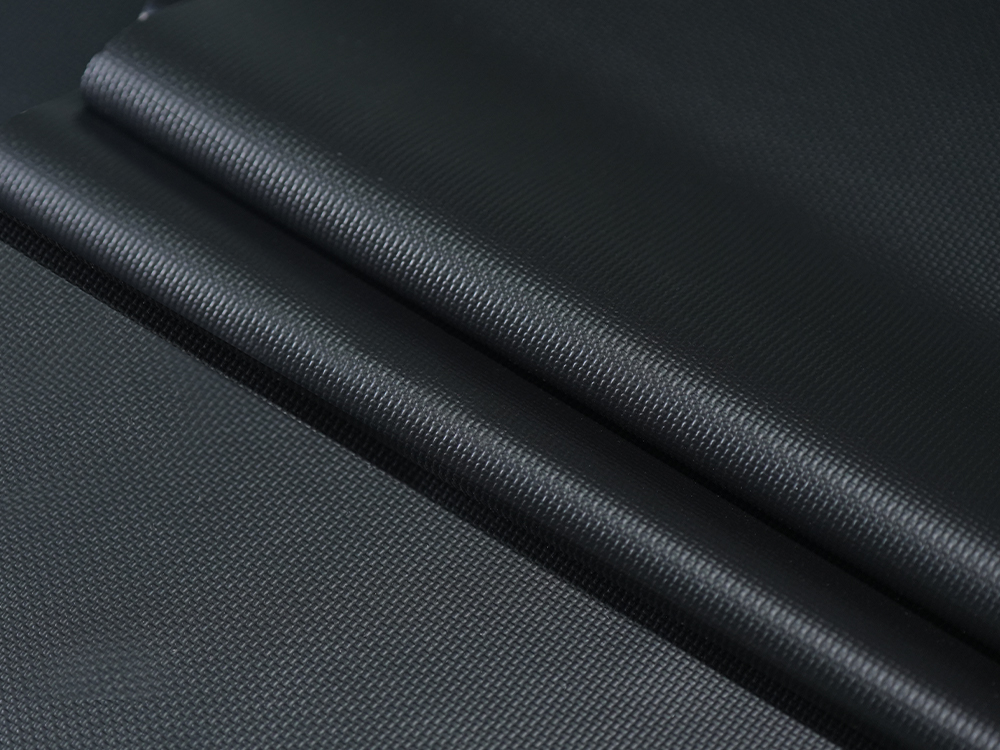

- Specialty Release Paper: Customized solutions for niche applications in the leather and packaging industry, often tailored by companies like Anhui Honghuan New Material Technology Co., Ltd. to meet unique industrial requirements.

Key Parameter Comparison

| Type | Coating | Heat Resistance | Moisture Resistance | Typical Applications |

|---|---|---|---|---|

| Silicone Coated | Silicone | Medium (up to 200°C) | Low | Leather embossing, lamination |

| High-Temperature Resistant | Advanced silicone/modified coatings | High (up to 300°C) | Medium | Hot stamping, high-temp lamination |

| PE-Coated | Polyethylene | Low (up to 120°C) | High | Moisture-sensitive leather processes |

| Specialty | Custom coatings | Varies | Varies | Customized industrial applications |

Selecting the Right Leather Release Paper

Choosing the proper leather release paper depends on your production requirements:

- For high-temperature operations, select high-temperature resistant release paper developed by Anhui Honghuan New Material Technology Co., Ltd.

- For moisture-prone environments, consider PE-coated leather release paper

- For standard embossing and laminating, silicone-coated paper is cost-effective and reliable

- For specialized industrial needs, contact Anhui Honghuan for customized release paper solutions

FAQ

1. What makes Anhui Honghuan New Material Technology Co., Ltd.'s leather release paper different from other suppliers?

Anhui Honghuan New Material Technology Co., Ltd., located in Shitan Industrial Park, Quanjiao County, Chuzhou City, Anhui Province, combines R&D, production, and sales to deliver high-quality leather release papers. Their innovative high-temperature-resistant release paper, developed in 2019, ensures superior performance for demanding industrial applications.

2. Can I get customized leather release paper for specific industrial processes?

Yes, Anhui Honghuan specializes in tailored solutions, including specialty coatings and PE-coated leather release paper. With strong technological expertise and a production facility covering 58 acres, the company can meet unique requirements efficiently.

English

English 中文简体

中文简体