Submit feedback

Custom Release Paper Finish Options Manufacturers

Industry Knowledge Extension

How is release paper finish applied in various industries such as footwear or furniture?

Release paper finish plays a critical role in modern industrial manufacturing, particularly in footwear, furniture, automotive interiors, and synthetic leather products. Its primary function is to act as a temporary carrier or protective layer for adhesives, coatings, and laminates, ensuring that the finished products maintain superior quality, surface uniformity, and operational efficiency. By understanding the applications and technical properties of release paper finish, manufacturers can optimize production processes and meet industry standards.

Overview of release paper finish

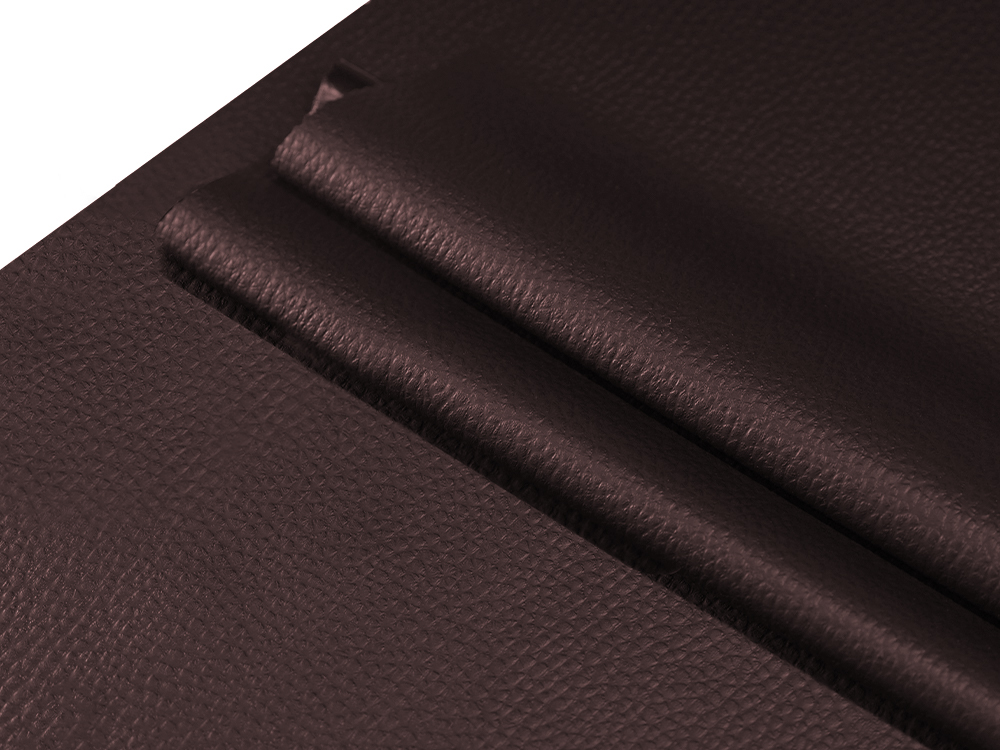

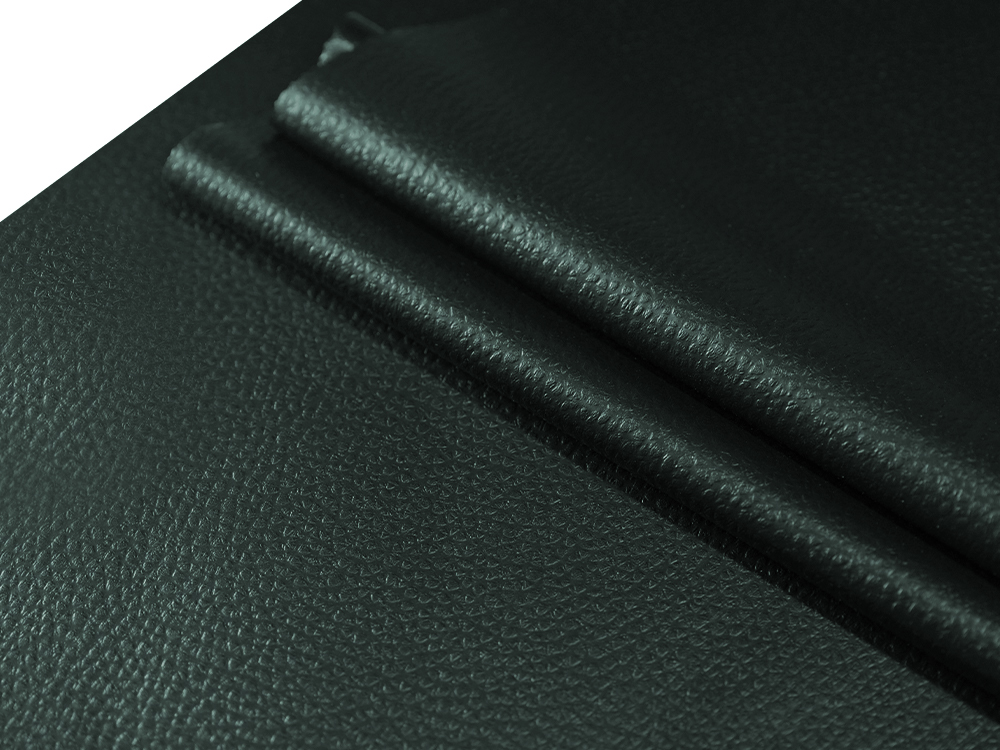

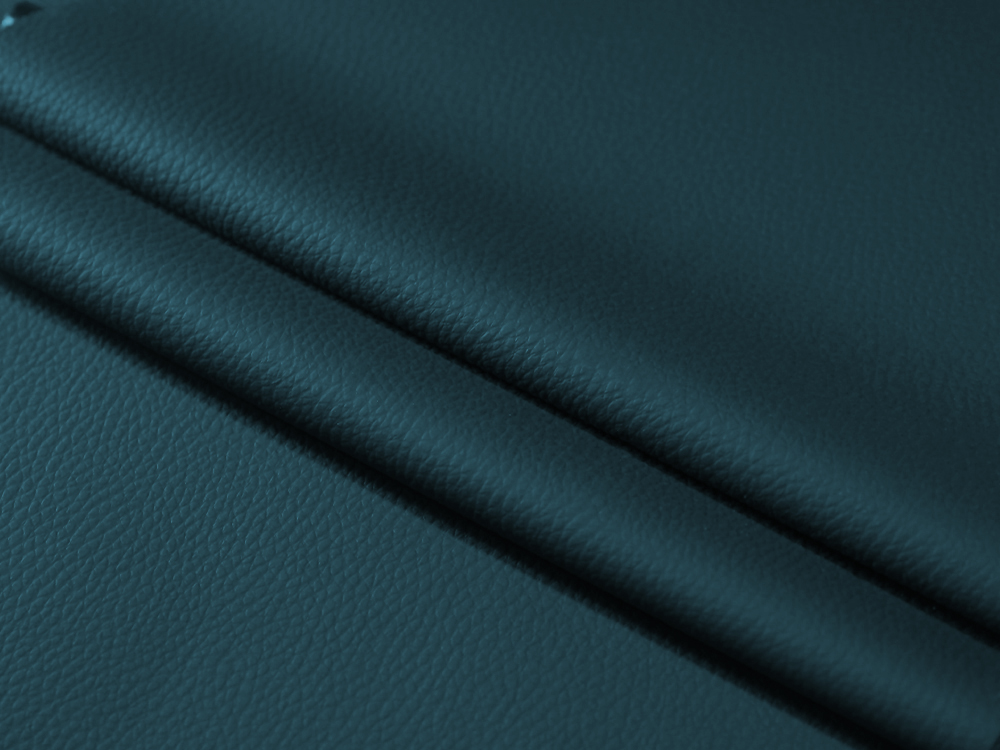

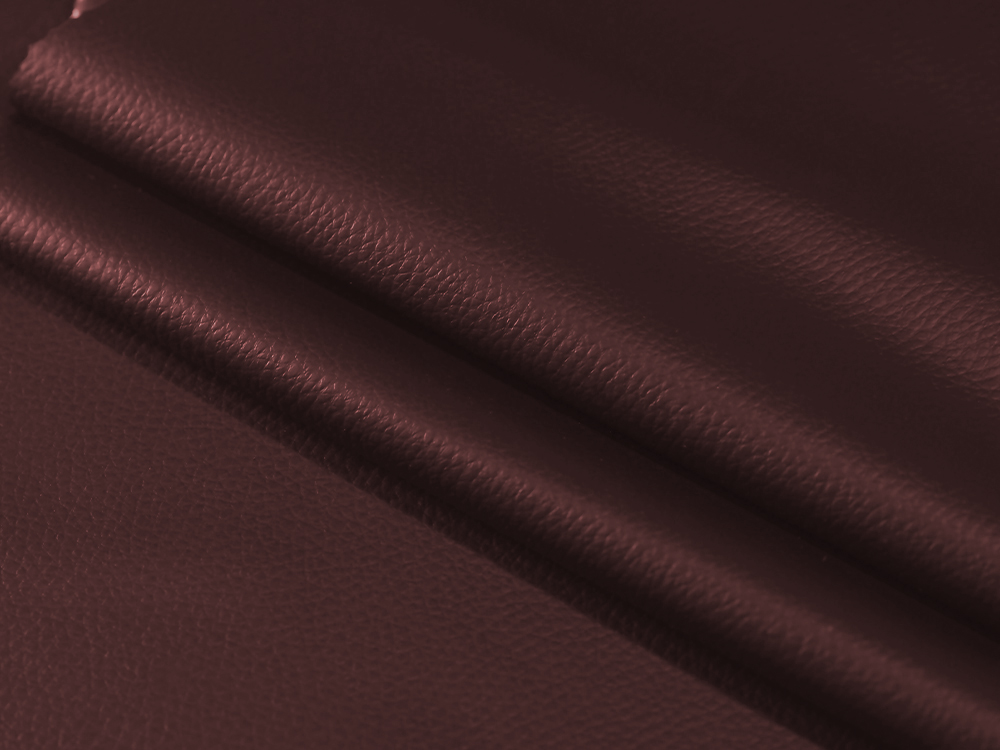

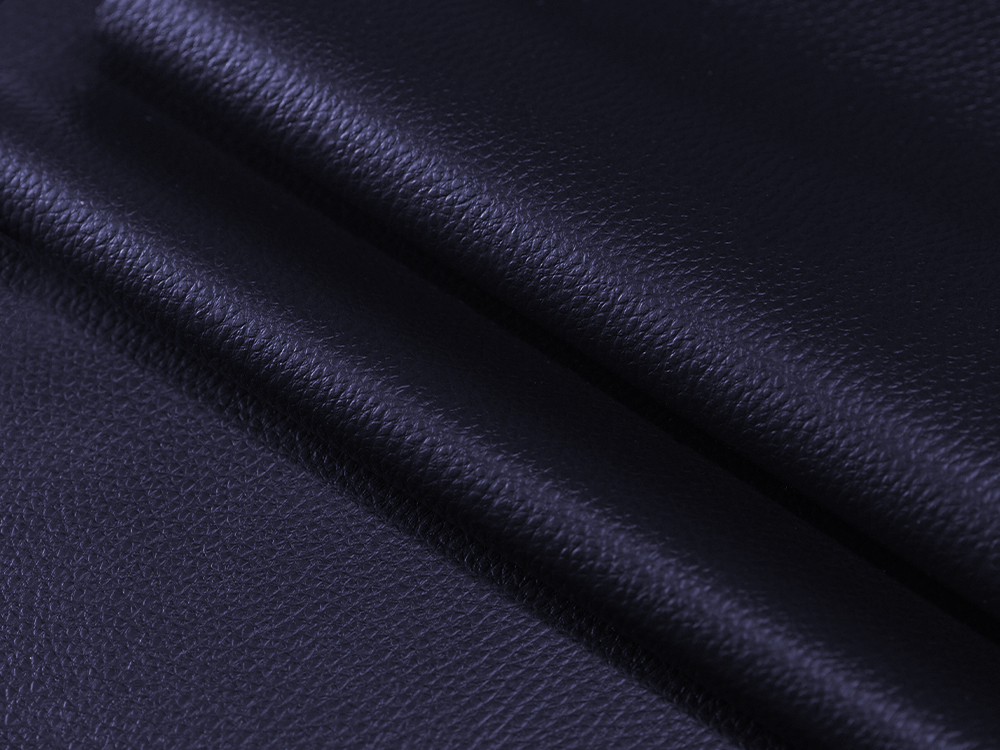

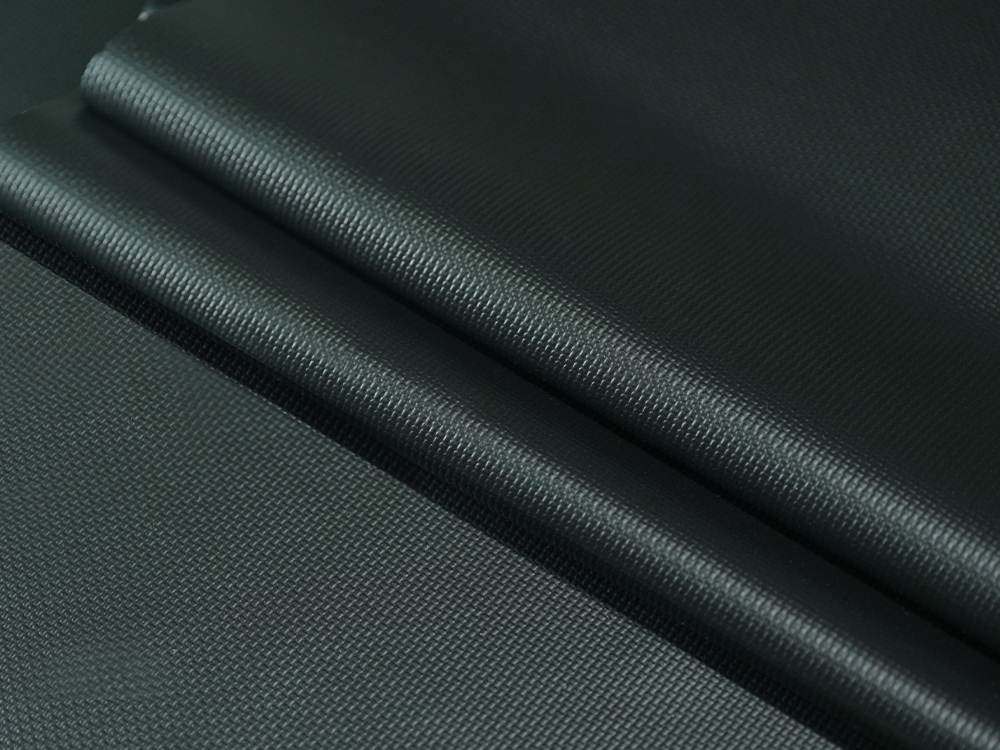

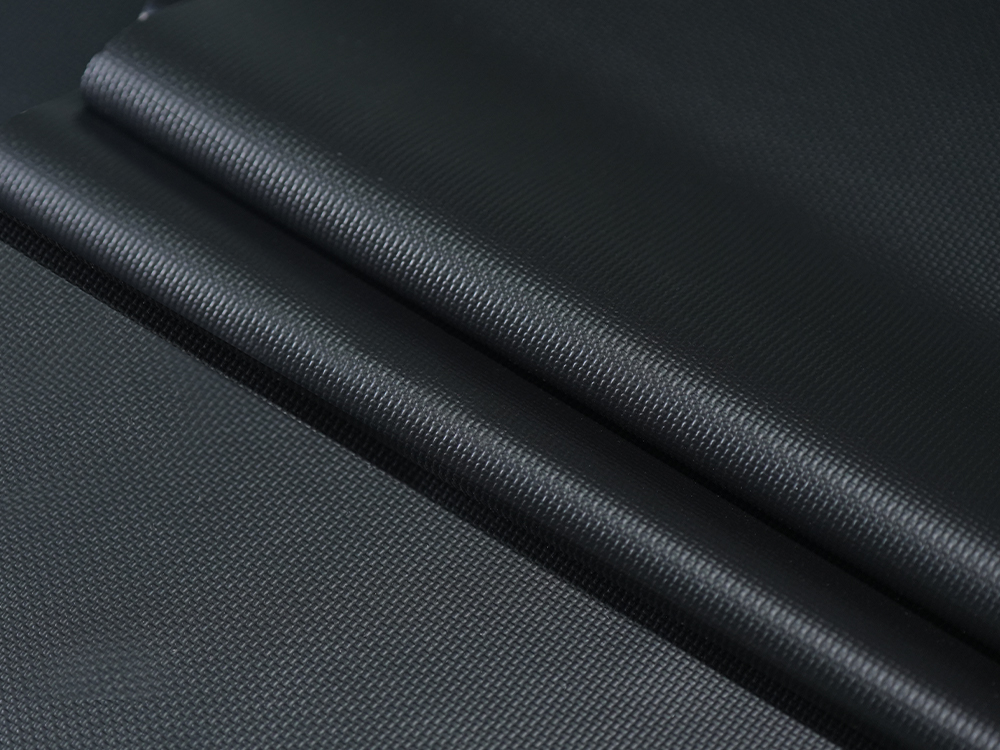

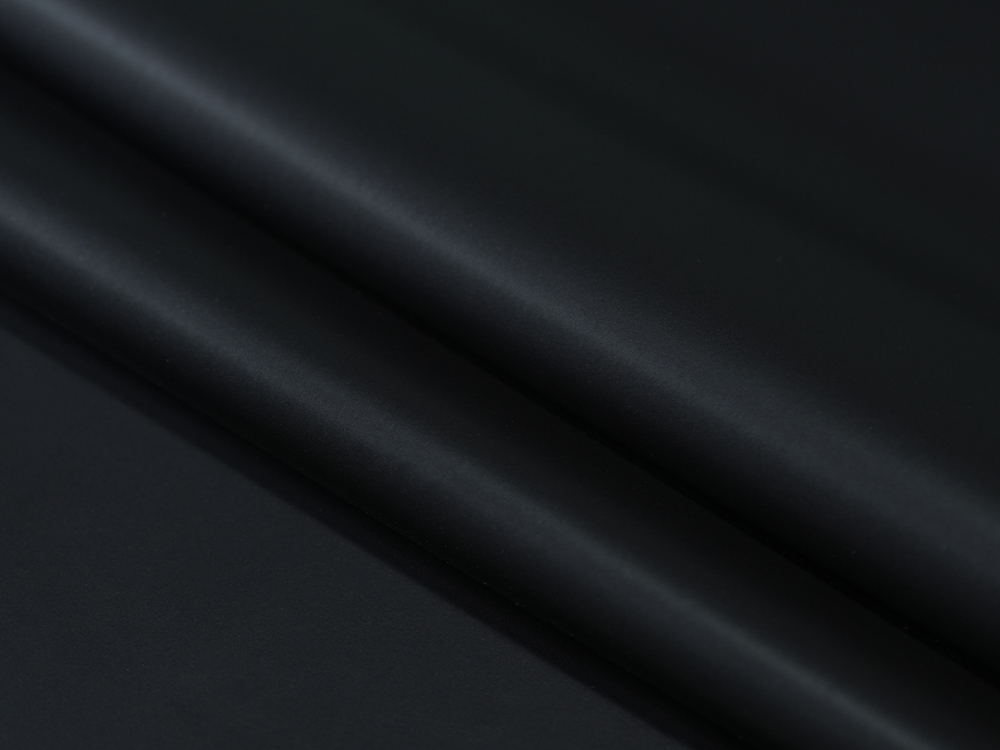

Release paper finish refers to paper that has been treated with a release agent on its surface, which allows coated materials such as polyurethane (PU), polyvinyl chloride (PVC), silicone, or other synthetic compounds to be easily removed after curing or lamination. Depending on the surface treatment, release paper finish can be smooth, matte, or patterned, directly influencing the surface gloss, texture, and overall appearance of the final product.

In industrial applications, release paper finish is categorized according to several technical parameters:

- Surface smoothness or gloss level

- Temperature and chemical resistance

- Dimensional stability under coating pressure

- Release force consistency

These factors determine how release paper finish interacts with adhesives, coatings, or synthetic leather layers during manufacturing.

Applications in the footwear industry

In the footwear industry, release paper finish is extensively used during the production of synthetic leather uppers, insoles, and laminated materials. The primary purposes include:

-

Surface protection during PU or PVC coating

Footwear manufacturers often apply PU or PVC coatings on synthetic leather. A properly selected release paper finish prevents sticking, reduces surface defects, and preserves the intended texture. -

Control of gloss and texture

Different shoe styles require distinct surface effects. Smooth release film ensures a polished, high-gloss finish, whereas textured or matte release paper finish can create subtle embossing or anti-slip textures. -

Enhanced production efficiency

High-temperature release paper finish allows for faster curing cycles, enabling rapid peel-off without compromising leather integrity. This contributes to consistent output and minimizes waste.

Applications in the furniture industry

For furniture manufacturing, release paper finish is crucial in processes such as laminating decorative sheets, applying protective coatings, or producing upholstered synthetic leather. Key applications include:

-

Surface consistency for laminates

Release paper finish ensures that laminated surfaces are smooth and free from bubbles or wrinkles. This is particularly important for high-end furniture where visual appearance is critical. -

Embossing and pattern replication

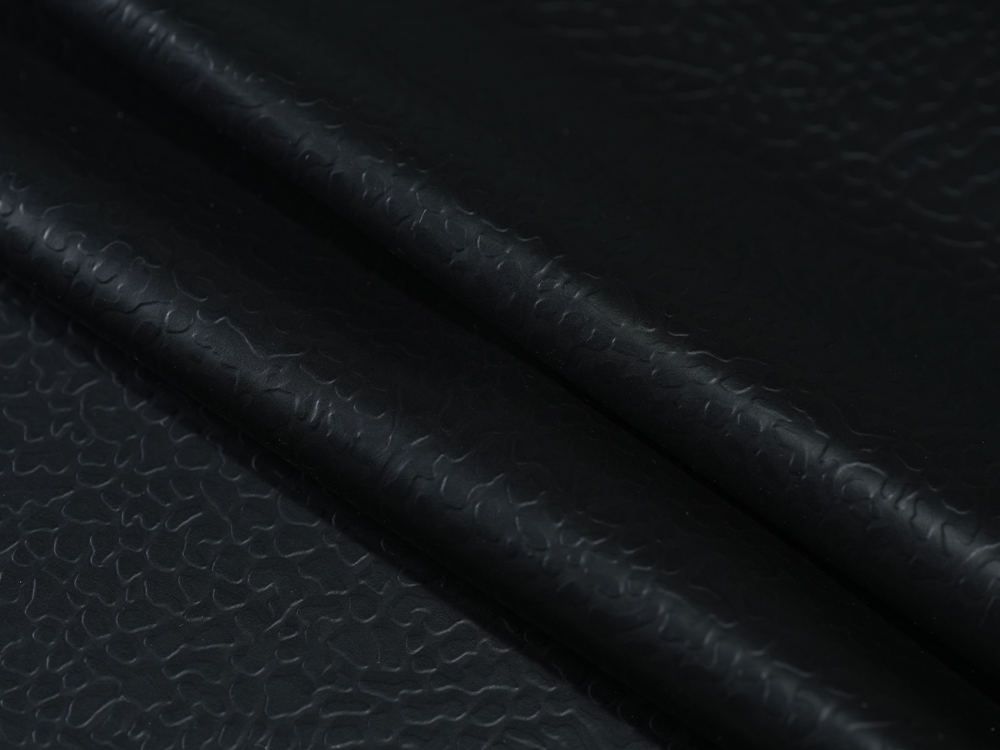

Textured release paper finish can transfer patterns onto synthetic leather used for furniture, creating designs such as wood grain, fabric textures, or geometric motifs. -

Anti-scratch and anti-fingerprint benefits

By selecting a release paper finish with the appropriate gloss and surface characteristics, manufacturers can reduce post-production defects, ensuring the furniture surface is resistant to scratches and fingerprints.

Technical considerations for release paper finish

Choosing the correct release paper finish involves understanding technical aspects that affect both production and the final product. These include:

Temperature resistance

High-temperature release paper finish is critical when working with thermally cured PU or PVC coatings. It ensures consistent release without causing surface deformation or chemical reactions with adhesives.

Surface gloss and texture control

The release paper finish directly affects the final gloss level and tactile feel of synthetic leather. Manufacturers can choose from ultra-matt, semi-matt, or glossy finishes depending on product specifications.

Peel force consistency

A uniform release force prevents surface defects such as stretching, tearing, or adhesive residue. Release paper finish with stable peel characteristics improves both quality control and operational efficiency.

Dimensional stability

During high-speed lamination or coating processes, release paper finish must maintain dimensional stability under pressure and temperature variations to prevent wrinkles or misalignment.

Material types and manufacturing methods

Release paper finish is typically made from base paper coated with silicone or other release agents. The production process requires precision to ensure uniform coating thickness and consistent surface properties. Modern manufacturers utilize automated and semi-automated lines, pilot coating machines, and analytical instruments to maintain quality standards.

Anhui Honghuan New Material Technology Co., Ltd, a leading manufacturer of high-temperature release paper for synthetic leather, offers a variety of release paper finish options. Their production system supports widths from 1,600mm to 2,350mm and can meet customized gloss levels and embossed designs, accommodating the specific needs of footwear, furniture, and other industries.

Comparison of release paper finish types

| Type | Surface Effect | Application |

|---|---|---|

| Smooth release film | Glossy, polished | High-gloss footwear, laminated furniture |

| Matt release paper | Low gloss, subtle | Anti-fingerprint synthetic leather, casual footwear |

| Textured release paper | Patterned/embossed | Decorative furniture, synthetic leather with tactile patterns |

| Ultra-matt release paper | Minimal reflection | Premium furniture and upholstery requiring subtle aesthetics |

This table highlights how the selection of release paper finish impacts the visual and tactile properties of synthetic leather in different industries.

Benefits of professional release paper finish

Selecting the right release paper finish offers multiple benefits:

- Improved product appearance: Surface gloss and texture can be controlled precisely.

- Operational efficiency: Reduced peeling defects and faster production cycles.

- Customizability: Tailored gloss levels, embossing patterns, and release forces.

- Durability: High-temperature and chemical-resistant finishes ensure product consistency.

By working with a professional manufacturer such as Anhui Honghuan, industries can access technical support, flexible production schedules, and stable supply chains for both small and large orders.

Industry trends and future outlook

The demand for release paper finish continues to grow alongside the expansion of synthetic leather applications. Key trends include:

- Sustainable materials: Environmentally friendly base papers and coatings.

- Advanced surface design: Micro-textures and embossed patterns for high-end markets.

- Process automation: Integration of automated lines for consistent quality and reduced labor costs.

Manufacturers are increasingly focusing on innovation in release paper finish to meet stricter industrial standards and evolving aesthetic preferences in footwear and furniture.

Conclusion

Release paper finish is a versatile and essential component in modern manufacturing for footwear, furniture, and synthetic leather products. Its role in controlling surface texture, gloss, peel consistency, and operational efficiency cannot be overstated. By understanding the applications and technical considerations, manufacturers can select the right type of release paper finish to ensure high-quality results, reduced production defects, and optimized performance.

FAQs

Q1: What is the primary function of release paper finish?

A: Release paper finish provides a temporary protective layer that allows adhesives, coatings, or laminates to be applied and removed without damaging the underlying material.

Q2: How does release paper finish affect surface gloss?

A: Different finishes, such as smooth, matte, or textured, directly influence the final appearance and tactile properties of synthetic leather or laminated surfaces.

Q3: Can release paper finish be customized?

A: Yes, professional manufacturers offer tailored gloss levels, embossing patterns, and width specifications to meet diverse industrial requirements.

Q4: Is release paper finish suitable for high-temperature applications?

A: High-temperature release paper finish is specifically designed to withstand thermal curing processes for PU, PVC, and other synthetic coatings.

Q5: What industries benefit most from release paper finish?

A: Footwear, furniture, automotive interiors, synthetic leather production, and decorative laminates are key industries that rely on release paper finish.

English

English 中文简体

中文简体