Submit feedback

Custom Release Paper Applied With Resin Manufacturers

Industry Knowledge Extension

How Does Release Paper Applied Resin Improve Industrial Production Efficiency?

In modern industrial production, the combination of release paper and resin is gradually becoming an indispensable key material in various high-performance manufacturing processes. However, many people still have questions about the application and advantages of "Release Paper Applied Resin": what substantial improvements does it actually bring to production?

What is Release Paper Applied Resin?

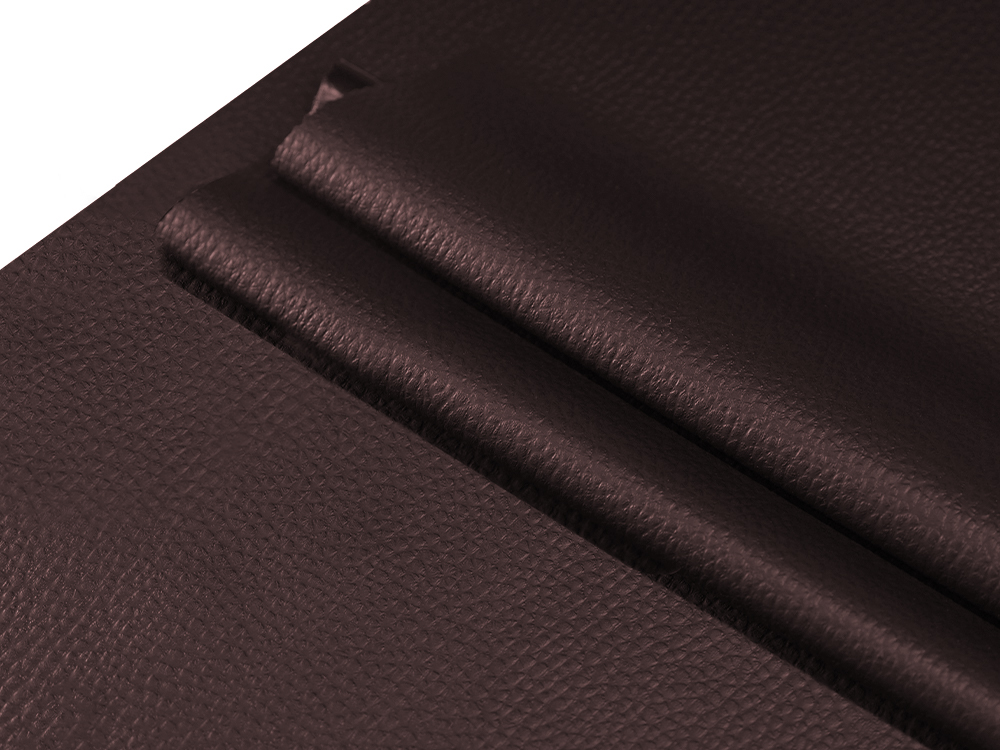

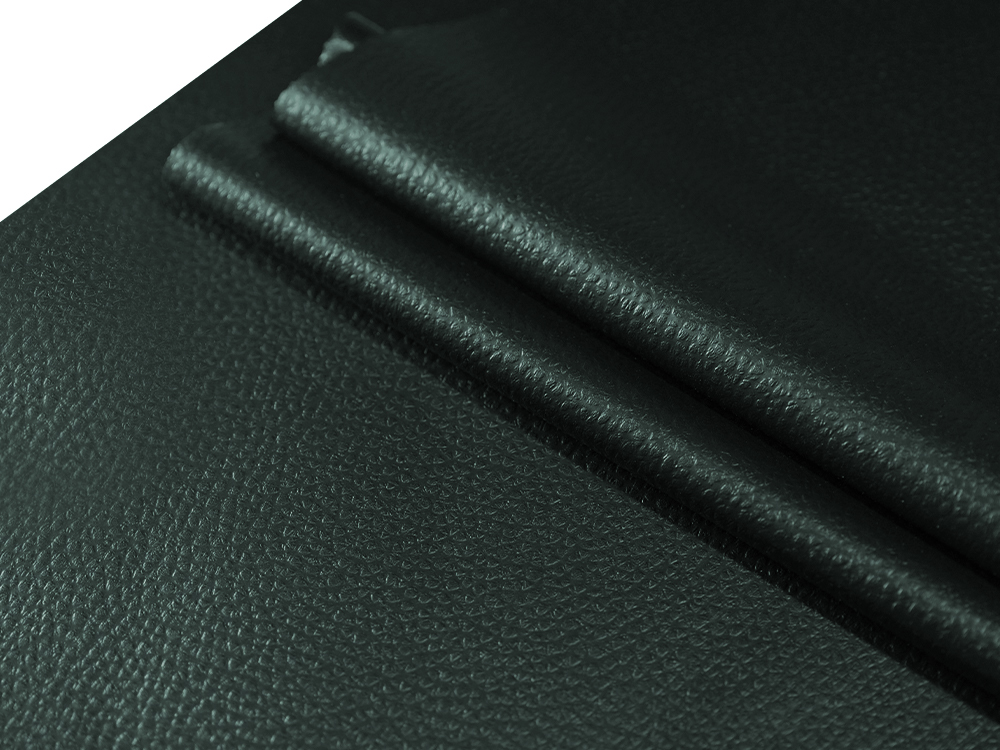

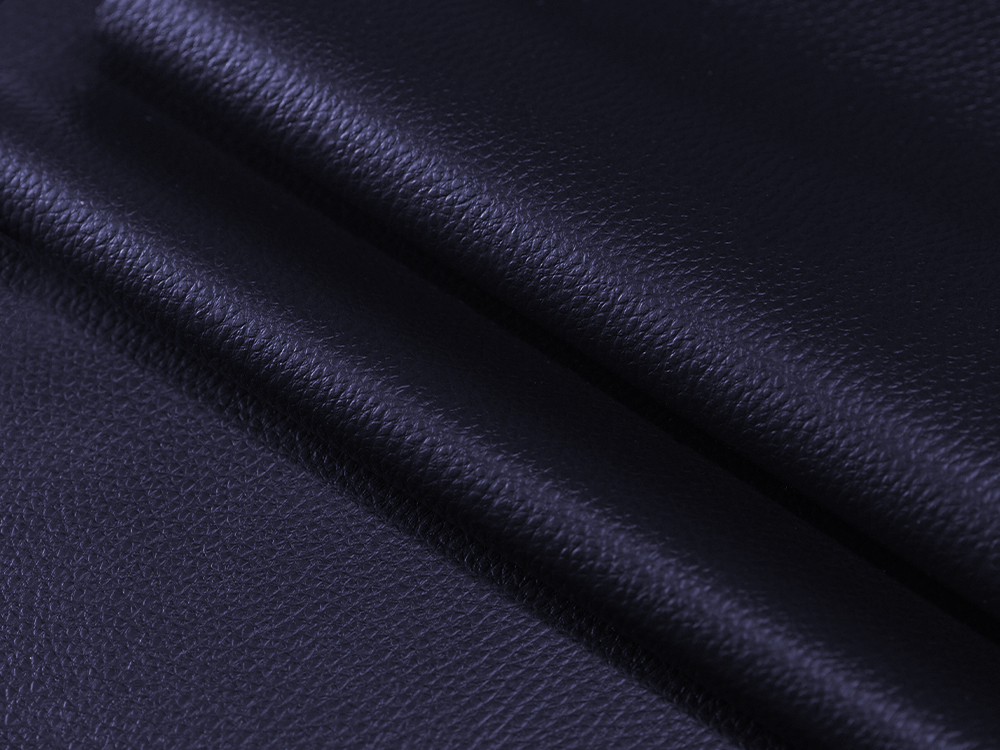

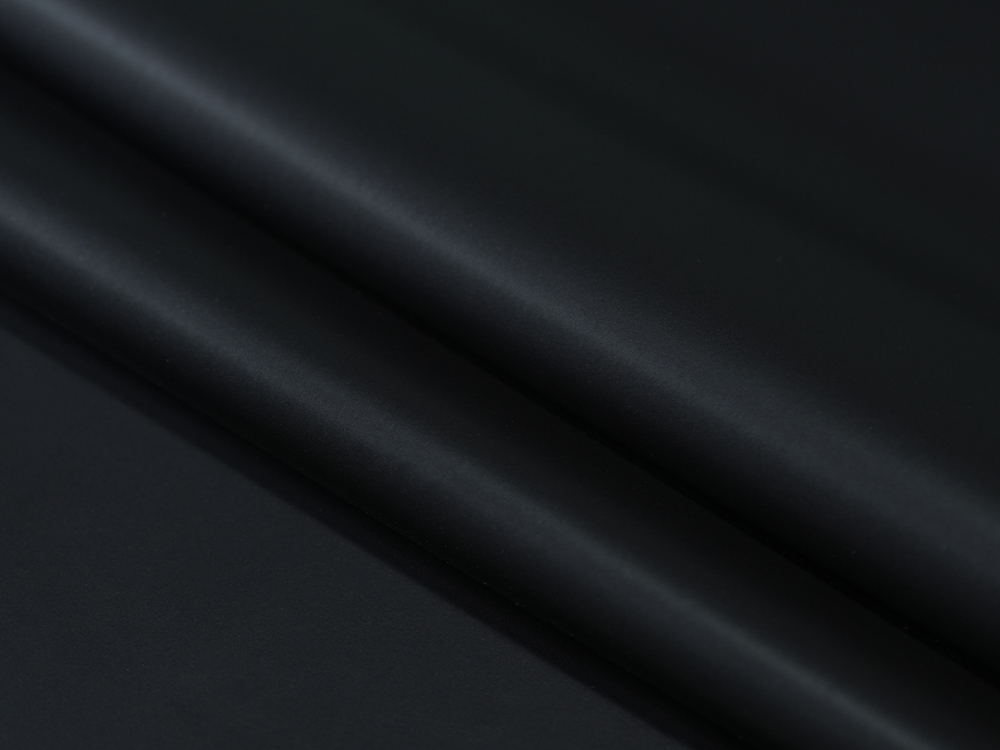

Release Paper Applied Resin is essentially a composite material formed by combining release paper and resin materials. Release paper, as a type of paper with a specially treated surface, can easily release adhesives, films, or other coatings under high temperature or high pressure conditions. Applied Resin refers to an optimized resin coating that gives it superior thermal stability, chemical resistance, and surface smoothness in specific industrial processes.

The core advantages of this composite material are:

- High-efficiency release: Reduces material adhesion and minimizes production line downtime.

- High-temperature resistance: Remains stable during high-temperature hot pressing or baking.

- Compatible with multiple resin systems: Suitable for various materials such as epoxy resin, polyester resin, and phenolic resin.

Through these characteristics, Release Paper Applied Resin demonstrates broad application potential in electronics, composite materials, packaging, and industrial molds.

Industrial Applications: How do release paper and resin improve production efficiency?

In actual industrial production, Release Paper Applied Resin functions in various ways:

1. Electronics and Semiconductor Industry

In electronic packaging and PCB (printed circuit board) manufacturing processes, high-temperature curing resins often adhere to the mold surface, leading to demolding difficulties. Using release paper to coat the resin allows for easy demolding at high temperatures, significantly reducing scrap rates and extending mold life.

2. Composite Material Processing

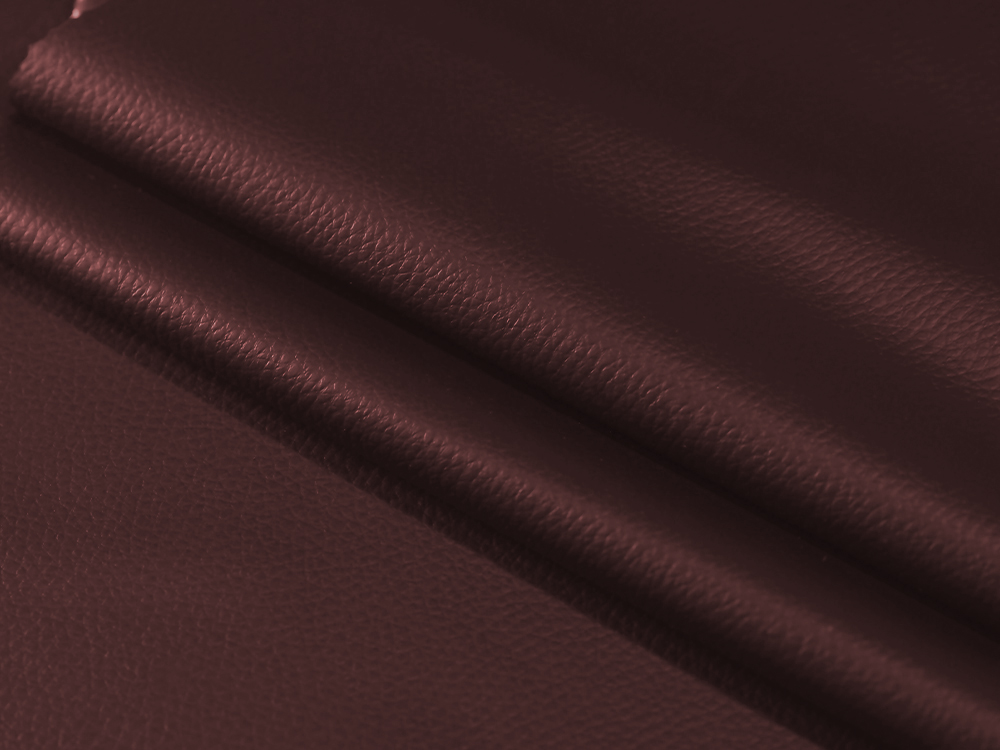

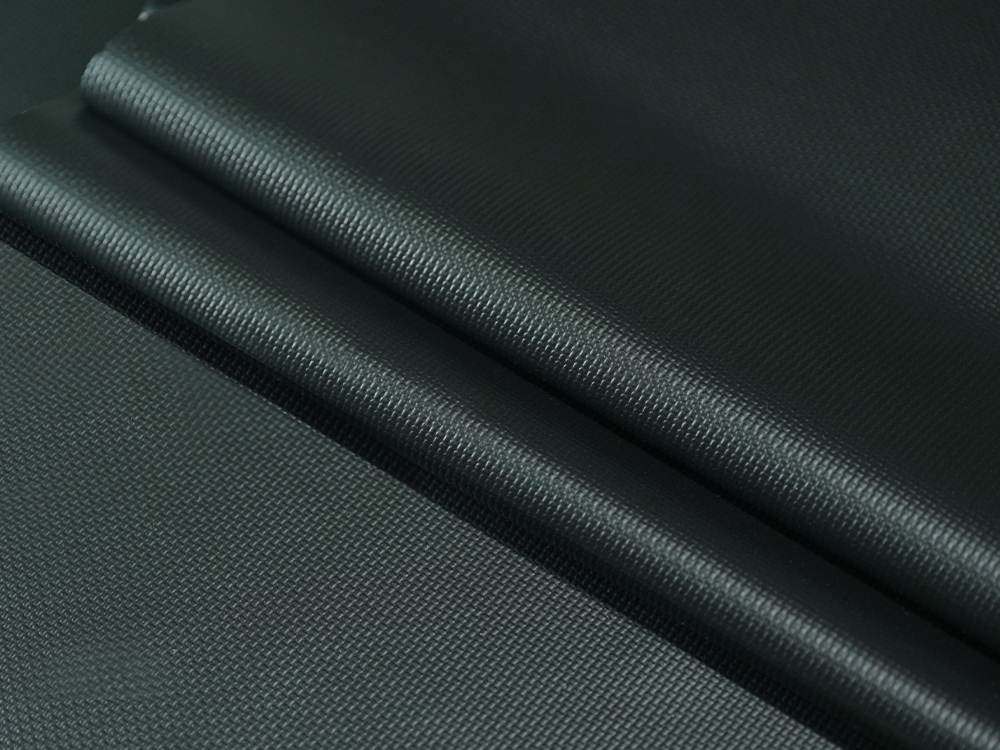

Carbon fiber composites are widely used in aerospace, automotive, and sporting goods industries. These materials typically require close contact between high-temperature resistant resin and the mold during molding. Release Paper Applied Resin not only ensures uniform resin distribution but also prevents material adhesion to the mold, improving the surface finish and structural integrity of the finished product.

3. High-End Packaging Materials

PE-coated paper and specially coated packaging materials are widely used in food, pharmaceutical, and electronics packaging. By coating release paper with resin, packaging materials are easier to handle in production, printing, and subsequent processing, reducing material waste and production costs.

Reasons to Choose Anhui Honghuan

As a leading company in this field, Anhui Honghuan New Material Technology Co., Ltd. possesses significant advantages:

- Strong R&D Capabilities: The company focuses on innovative R&D of release paper, PE-coated paper, and high-end packaging materials. In 2019, it successfully developed high-temperature resistant release paper, providing high-performance solutions for the industry.

- Superior Geographic Location: Located in Shitan Industrial Park, Quanjiao County, Chuzhou City, Anhui Province, the company enjoys convenient transportation with complete highway, railway, and airport facilities, ensuring rapid response to customer needs.

- Comprehensive Production System: A comprehensive enterprise model covering R&D, production, and sales enables technological achievements to be quickly transformed into industrial application products, ensuring stable supply and reliable quality.

- Investment and Scale Advantages: A modern factory covering 58 acres, invested in by Kunshan FASTER New Materials Group with 300 million RMB, provides the foundation for large-scale production, capable of meeting various high-end customized needs.

These advantages enable Anhui Honghuan to provide customers with end-to-end solutions from material selection and customized development to mass production, helping enterprises gain significant advantages in improving production efficiency and product quality.

Technological Innovation: The Value of High-Temperature Resistant Release Paper

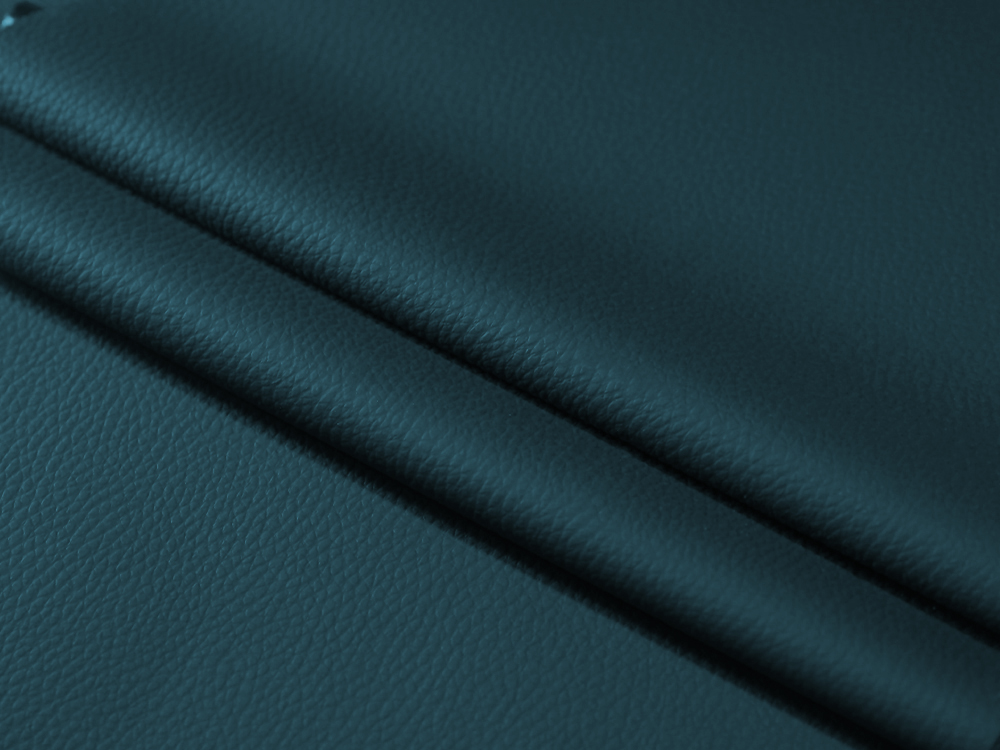

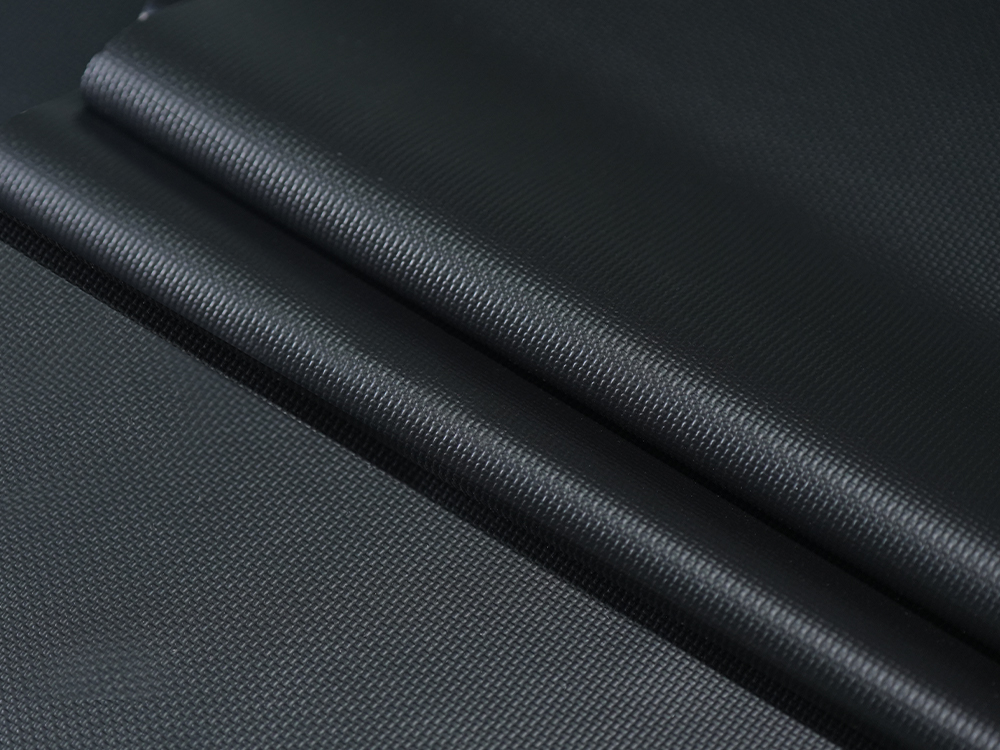

High-temperature resistant release paper is one of Anhui Honghuan's core technologies. Compared with ordinary release paper, it maintains stable structure and release performance under high-temperature environments, making it particularly suitable for thermosetting resin processes.

Technical features include:

- High-Temperature Resistance: Can withstand continuous hot pressing at temperatures above 200℃ without deformation.

- Surface Uniformity: Ensures a smooth, bubble-free, and defect-free surface for composite materials.

- Strong Compatibility: Suitable for various industrial resin systems such as epoxy resin, polyester resin, and phenolic resin.

This innovative technology not only improves production efficiency but also significantly reduces material waste and labor costs, creating direct economic benefits for customers.

Future Outlook: Innovative Trends in Release Paper and Resins

With the increasing demand for industrial automation and high-performance materials, the research and development of Release Paper Applied Resin will focus on the following directions:

- Higher temperature and chemical resistance to meet the extreme environmental requirements of aerospace, electronic packaging, and other fields.

- Functionalized release surfaces, such as antistatic, UV-resistant, and antibacterial coatings, to expand application scenarios.

- Sustainable materials, combining environmentally friendly resins with biodegradable paper-based materials to achieve green manufacturing.

Anhui Honghuan is actively developing these cutting-edge technologies, leveraging its strong R&D capabilities and complete production system to provide customers with the most advanced and reliable material solutions.

In modern industry, efficiency, quality, and cost control are the core of a company's competitiveness. Release Paper Applied Resin, with its unique high-temperature resistance, excellent release properties, and wide applicability, provides a solid guarantee for companies in optimizing production processes and improving product quality. Choosing a technology-leading company like Anhui Honghuan New Material Technology Co., Ltd. further ensures the efficiency and reliability of materials from R&D to production.

English

English 中文简体

中文简体