Submit feedback

How to select the appropriate high-temperature leather release paper in the production of synthetic leather?

When selecting the appropriate high-temperature leather release paper in the production of synthetic leather, multiple factors need to be considered. The following are some key points:

High-temperature resistance: During the production process of synthetic leather, it usually goes through a high-temperature treatment process. Therefore, the high-temperature resistance of the release paper is of great importance. Generally speaking, the appropriate release paper should be selected according to the specific high-temperature conditions in the production process. For example, if the maximum temperature in the production process reaches 200°C, a release paper that can withstand a temperature of more than 200°C should be selected to ensure that the release paper will not deform, become brittle, or adhere to the synthetic leather material at high temperatures.

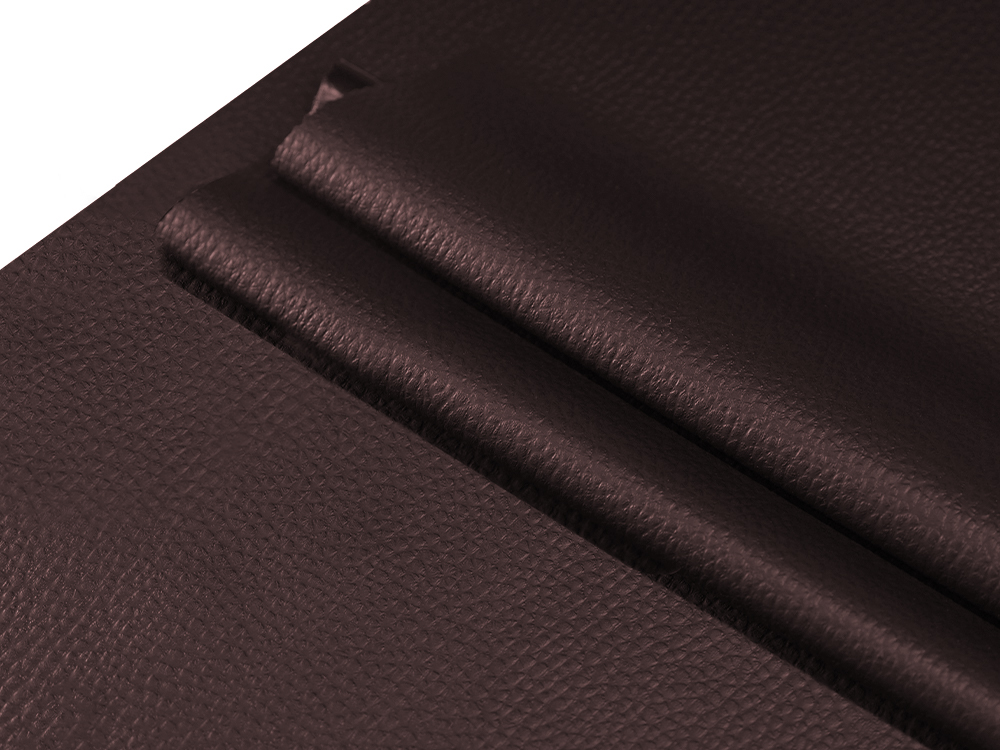

Release performance: The release performance of the release paper directly affects the quality and production efficiency of synthetic leather products. High-quality release paper should have good release effects, that is, it should be able to easily separate from the leather surface after the synthetic leather is formed, and no substances should remain on the leather surface to avoid affecting the appearance and performance of the synthetic leather. The release performance of the release paper can be evaluated by testing the release force. Generally, the release force is required to be moderate. It should not be too large, causing difficulties in release, nor should it be too small, making the leather surface likely to separate from the release paper during the production process.

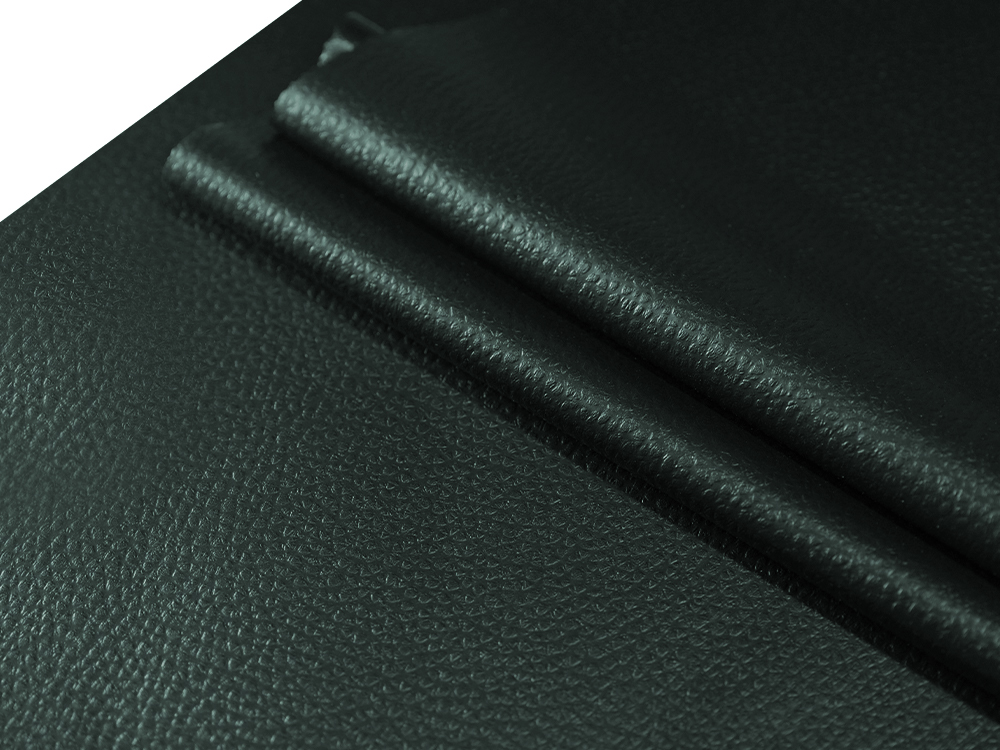

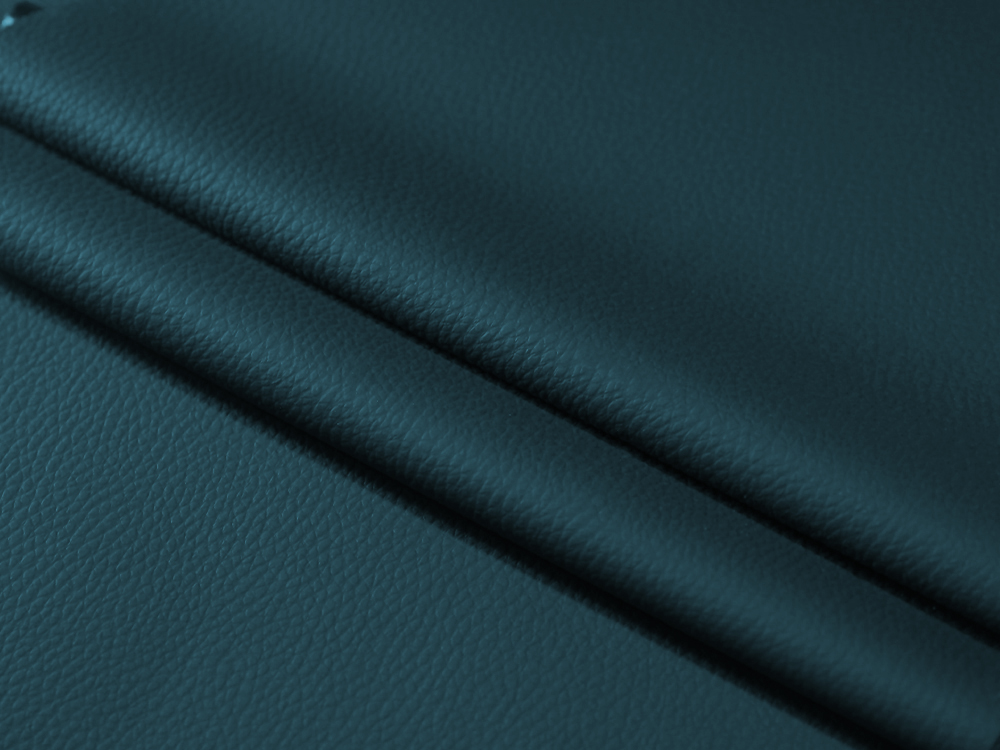

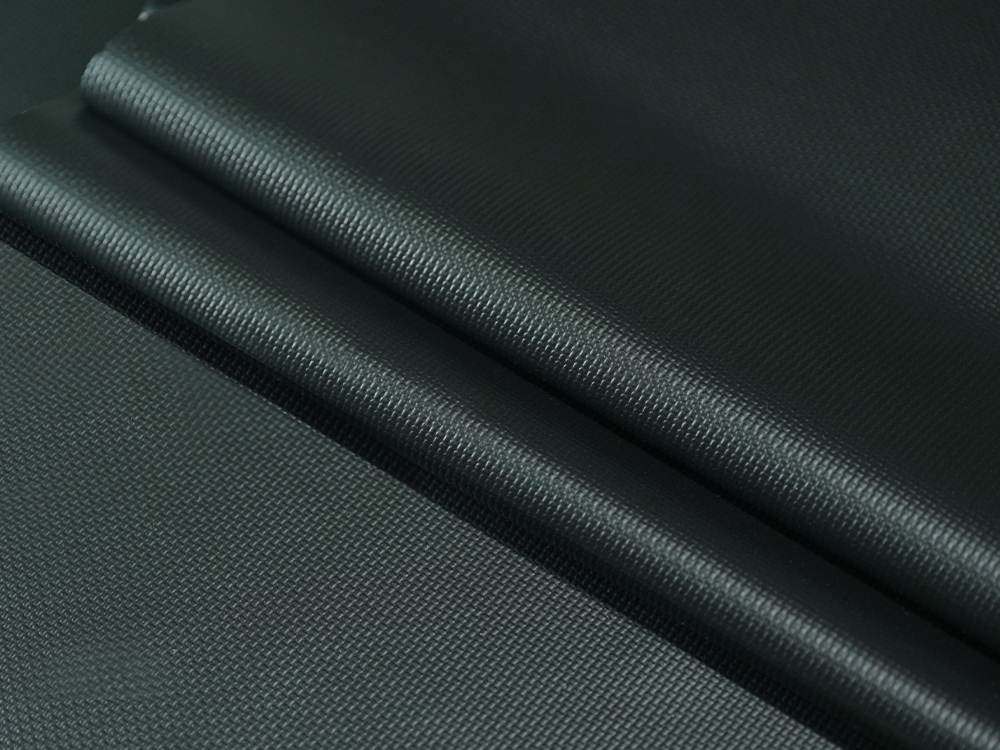

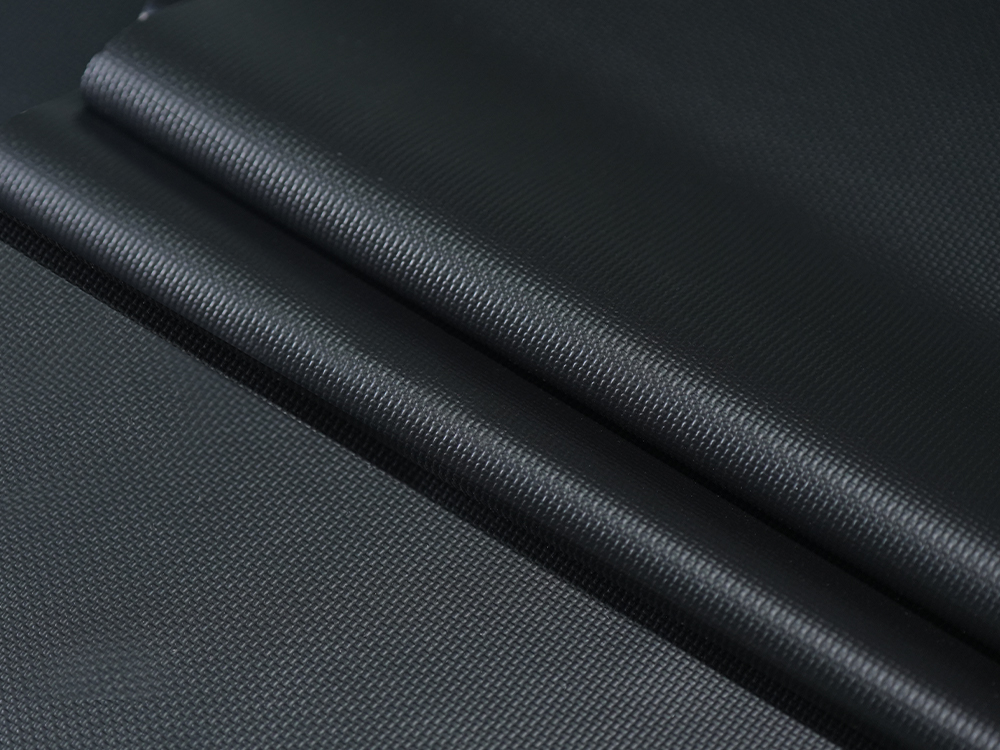

Surface flatness: The surface flatness of the release paper has an important impact on the appearance quality of synthetic leather. If the surface of the release paper is uneven, it will cause the surface of the synthetic leather to be uneven or have texture defects, affecting the aesthetic appearance and hand feel of the product. Therefore, release paper with high surface flatness and good smoothness should be selected to ensure that the synthetic leather can obtain a uniform surface effect.

Physical strength: During the production process of synthetic leather, the release paper needs to withstand a certain tension and pressure. Therefore, it needs to have sufficient physical strength, including tensile strength, tear strength, etc. Release paper with high physical strength is not easy to be damaged during the production process, ensuring the smooth progress of production and reducing the scrap rate of synthetic leather caused by the damage of the release paper.

Chemical stability: The release paper should have good chemical stability and should not react chemically with various chemical raw materials used in the production process of synthetic leather. Once a chemical reaction occurs, it may change the properties of the release paper, affecting the release effect, and may even have an adverse impact on the quality of the synthetic leather, such as causing the leather surface to change color or become hard.

Air permeability: Appropriate air permeability helps with the drying and curing of synthetic leather during the production process, which can improve production efficiency and product quality. Release paper with good air permeability can make it easier for the solvents and moisture inside the synthetic leather to volatilize, reducing the drying time, and also helps to prevent problems such as bubbles or surface cracking of the synthetic leather during the drying process.

Cost factor: On the premise of meeting the production quality requirements, the cost is also one of the important factors to consider when selecting release paper. There are differences in the prices of release papers of different brands and specifications. The production cost and product profit should be comprehensively considered, and release paper with high cost-effectiveness should be selected. At the same time, the service life and loss of the release paper also need to be considered. Some release papers with higher prices but good quality and long service life may have more cost advantages in long-term use.

English

English 中文简体

中文简体