Submit feedback

Custom Ultra Matt Release Paper Manufacturers

Industry Knowledge Extension

What are the surface smoothness and texture specifications for Ultra Matt Release Paper?

Ultra matt release paper has become a critical material in industries that demand precise surface finishes, particularly in synthetic leather production. Its primary role is to ensure that coated surfaces, laminates, and synthetic materials maintain their intended matte appearance without defects such as sticking, uneven textures, or gloss inconsistencies.

Overview of ultra matt release paper

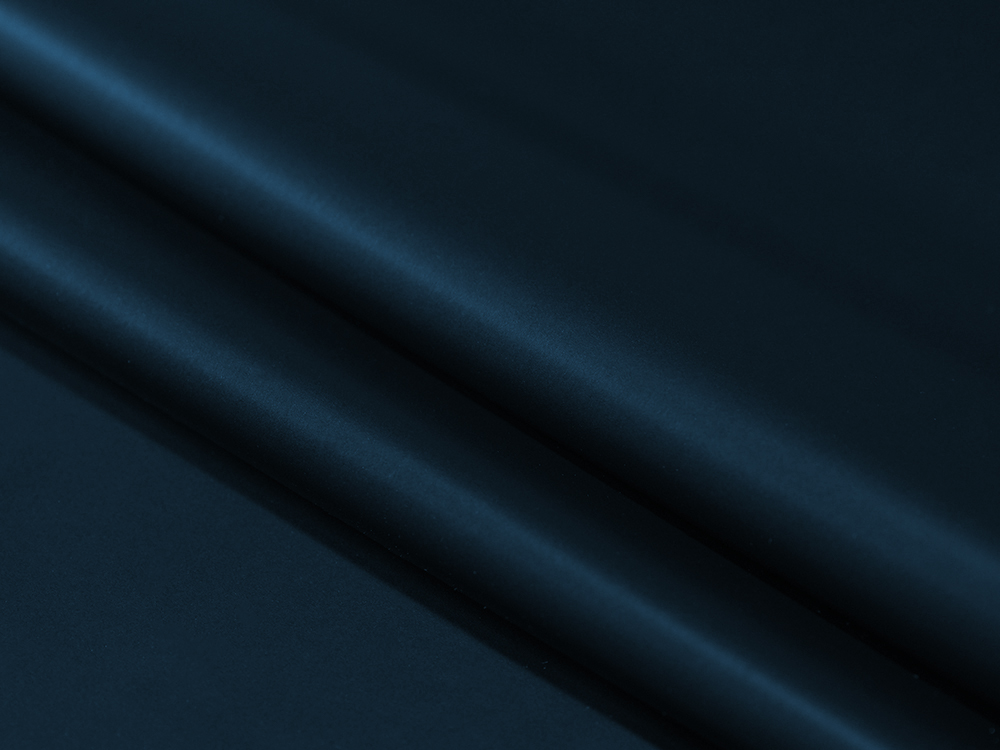

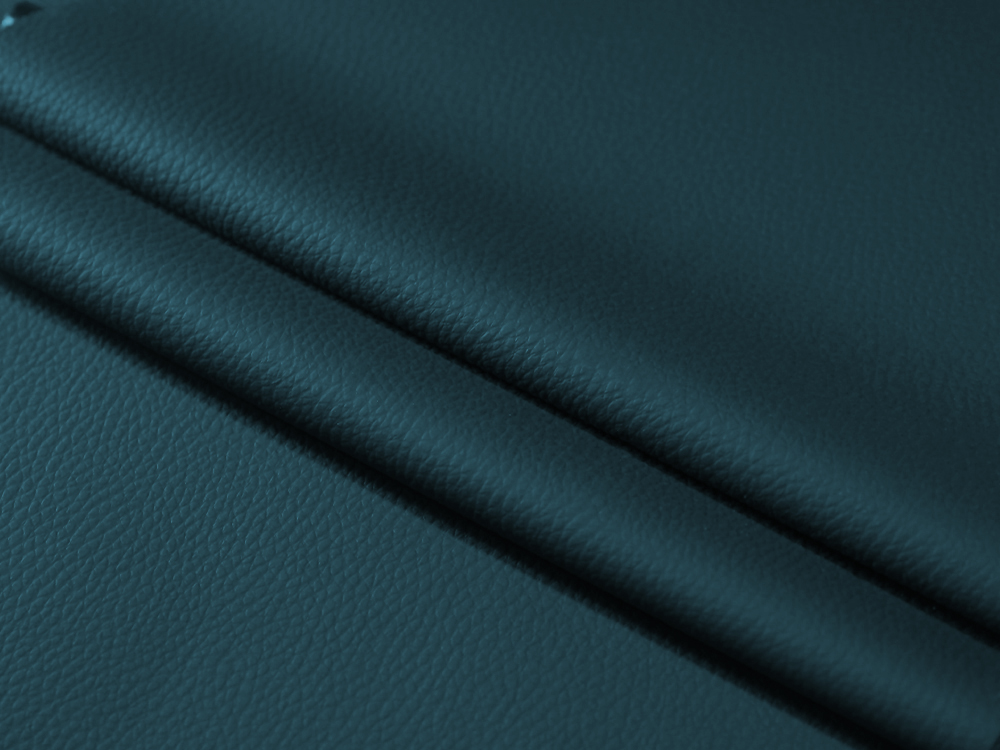

Ultra matt release paper is designed to provide a non-glossy, uniform surface that enables high-quality finishing of synthetic leather, PVC, PU, and other coated materials. Unlike glossy or semi-gloss release papers, ultra matt release paper ensures minimal reflection and a consistent matte appearance, making it highly desirable for flooring, furniture, automotive interiors, and other applications where visual and tactile quality is critical.

The paper is typically made with a high-temperature-resistant coating, which allows it to withstand industrial processes without compromising surface integrity. Key user search terms for this material include non-glossy release paper, matt release paper, and smooth release film, reflecting buyer interest in its performance and surface characteristics.

Technical characteristics affecting surface smoothness

The surface smoothness of ultra matt release paper is determined by several interrelated factors:

Coating composition and uniformity

The coating applied to ultra matt release paper is engineered to achieve a specific micro-texture. The uniform distribution of release agents ensures that coated materials do not stick and that the surface finish remains consistent.

Base paper quality

The smoothness of the underlying paper substrate is crucial. Ultra matt release paper typically uses high-quality kraft or specialty base paper, which provides a stable foundation for the release coating. Variations in base paper density, fiber arrangement, or thickness can directly impact the final surface texture.

Calendering and surface finishing

Advanced calendering processes are used to control the surface roughness and tactile feel of ultra matt release paper. By adjusting pressure and temperature during production, manufacturers can achieve a balance between smoothness and the desired matte effect.

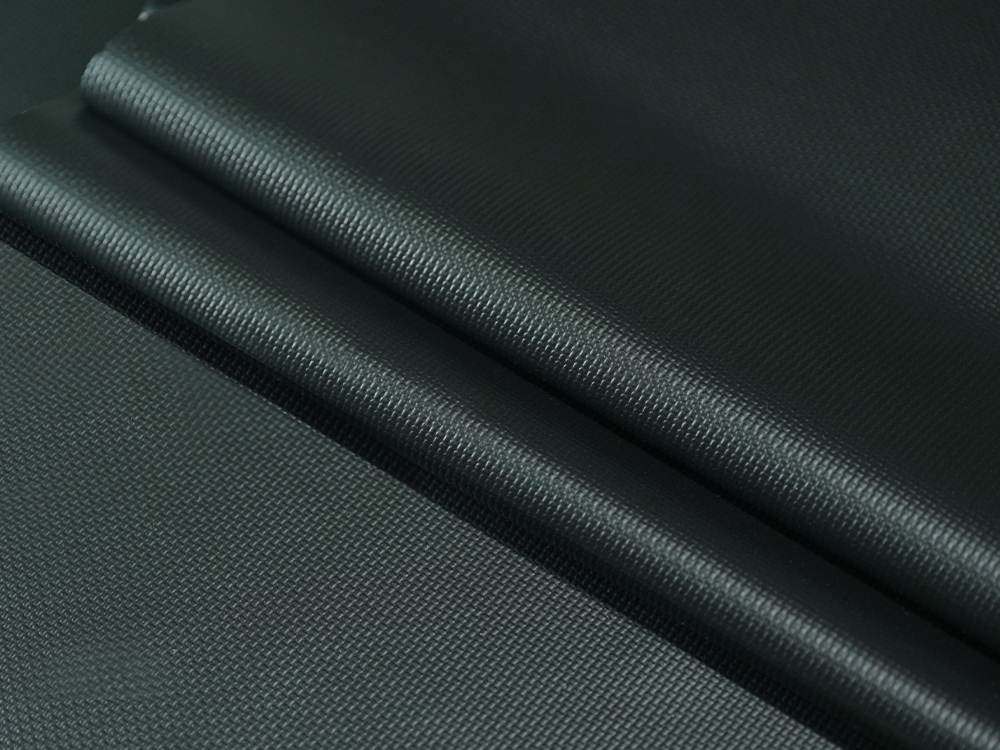

Texture specifications of ultra matt release paper

The texture of ultra matt release paper is often quantified in terms of matte level, uniformity, and embossing capability. These specifications are critical for ensuring consistent results in coated or laminated products.

| Specification | Description | Industrial relevance |

|---|---|---|

| Matte level | Low gloss, measured to ensure minimal light reflection | Essential for furniture and flooring finishes |

| Surface roughness | Micro-texture adjusted for non-stick performance | Prevents defects in PU/PVC coatings |

| Embossing capability | Compatibility with embossing patterns | Enables decorative and functional textures |

| Thickness tolerance | Typically between 50–100 μm | Ensures consistency in high-speed production |

| Temperature resistance | Up to 180–200°C | Supports high-temperature lamination and coating |

Performance benefits in industrial applications

Ultra matt release paper provides several advantages in industrial settings:

- Anti-stick performance: The precise coating ensures that adhesives or resins do not adhere to the paper, protecting both the product and the equipment.

- Surface consistency: Manufacturers benefit from a predictable matte finish, which reduces post-production defects and improves aesthetic quality.

- High-temperature resilience: Ultra matt release paper can endure elevated processing temperatures without warping or degrading, making it suitable for PU or PVC synthetic leather production.

- Customization for embossing and designs: The paper supports tailored gloss levels and EMB designs, which is important for brands seeking unique patterns or finishes.

Manufacturing and quality control

Producers of ultra matt release paper, such as Anhui Honghuan New Material Technology Co., Ltd, utilize an integrated approach combining R&D, production, and sales to maintain high-quality standards. Key aspects include:

- Advanced testing equipment: Analytical instruments and pilot coating machines ensure uniform coating thickness and surface texture.

- Automated production lines: Automated and semi-automated lines enhance consistency, production efficiency, and capacity.

- Strict cycle time controls: Each batch undergoes quality checks from design to final output, guaranteeing stable surface properties.

- Raw material stability: A secure supply chain for base paper and chemical coatings prevents variability in texture and performance.

Application areas

Ultra matt release paper is widely used in industries requiring high-quality matte finishes:

- Synthetic leather for furniture: Ensures anti-fingerprint and scratch-resistant surfaces.

- Automotive interiors: Provides uniform matte finishes for dashboards, door panels, and seating.

- Flooring materials: Supports consistent visual quality and texture for PVC or PU-based floor coverings.

- Decorative laminates: Enables embossing and pattern design while preserving surface smoothness.

Specifications customization and order flexibility

Manufacturers can tailor ultra matt release paper to meet specific industrial requirements:

- Width adjustment: Commonly available in widths from 1,600mm to 2,350mm.

- MOQ flexibility: Orders can start from 2,000 meters per roll to support smaller clients.

- OEM/ODM support: Customized gloss levels, embossing patterns, and other properties are available.

- Fast delivery: Efficient logistics ensure timely supply for high-volume or urgent projects.

Key considerations for buyers

When selecting ultra matt release paper, buyers should consider:

- Compatibility with coatings: Ensure the release paper matches the resin or PU/PVC formulation.

- Surface roughness requirements: Choose the appropriate micro-texture for the desired matte effect.

- Temperature resistance: Confirm the paper can endure the processing temperatures of the production line.

- Embossing and pattern needs: Verify that the release paper supports decorative or functional embossing.

- Supplier reliability: Select manufacturers with robust production systems and consistent quality control.

Conclusion

Ultra matt release paper is a specialized material that plays a vital role in producing high-quality matte finishes for synthetic leather and other coated surfaces. Its surface smoothness and texture specifications directly impact product aesthetics, anti-stick performance, and embossing capabilities. By understanding these technical aspects, manufacturers can select the most suitable release paper, ensuring consistent performance across industrial applications.

Anhui Honghuan New Material Technology Co., Ltd exemplifies a professional manufacturer, offering customizable ultra matt release paper solutions with strict quality control, advanced production technology, and reliable after-sales support.

FAQs about Ultra Matt Release Paper

Q1: What is the main function of ultra matt release paper?

A1: Its main function is to provide a non-glossy, consistent surface that prevents sticking and maintains high-quality finishes on coated or laminated materials.

Q2: Can ultra matt release paper be reused?

A2: Depending on the coating and industrial process, ultra matt release paper can often be reused multiple times while maintaining its matte surface performance.

Q3: What industries commonly use ultra matt release paper?

A3: It is widely used in synthetic leather production, automotive interiors, flooring, and decorative laminates.

Q4: How is the surface smoothness of ultra matt release paper controlled?

A4: Smoothness is controlled through high-quality base paper, uniform coating application, and precise calendering during production.

Q5: Can the matte level be customized?

A5: Yes, manufacturers can adjust the coating and texture to achieve specific gloss levels or embossing patterns according to customer requirements.

English

English 中文简体

中文简体