Submit feedback

Custom Semi Matt Release Paper Manufacturers

Industry Knowledge Extension

How does the porosity of Semi Matt Release Paper affect air bubble prevention in coatings?

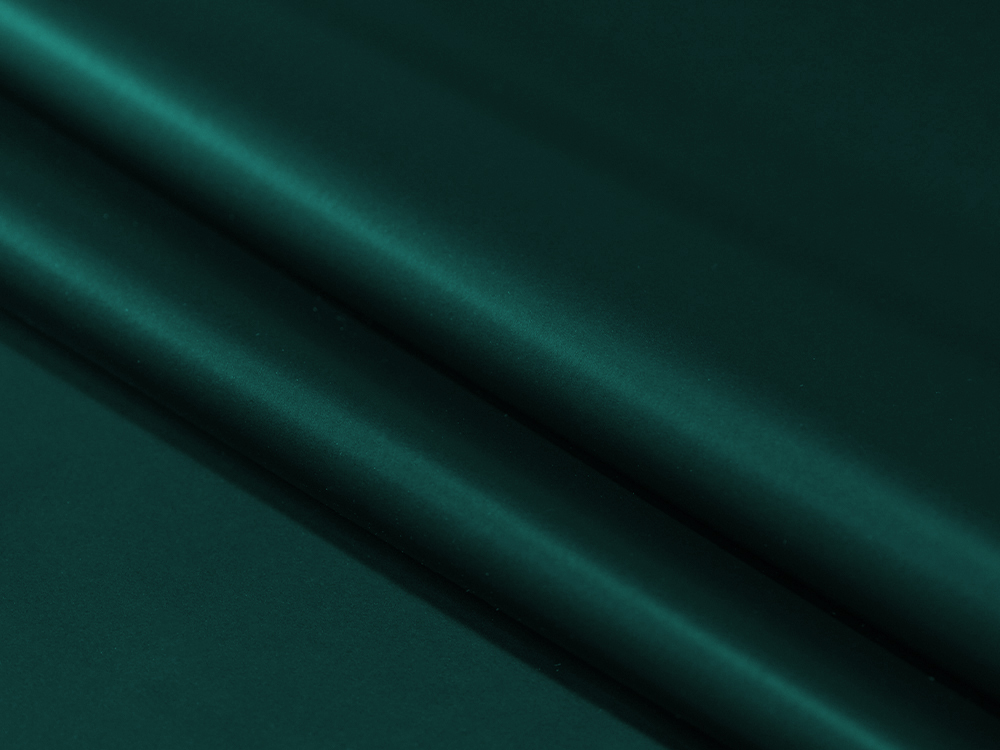

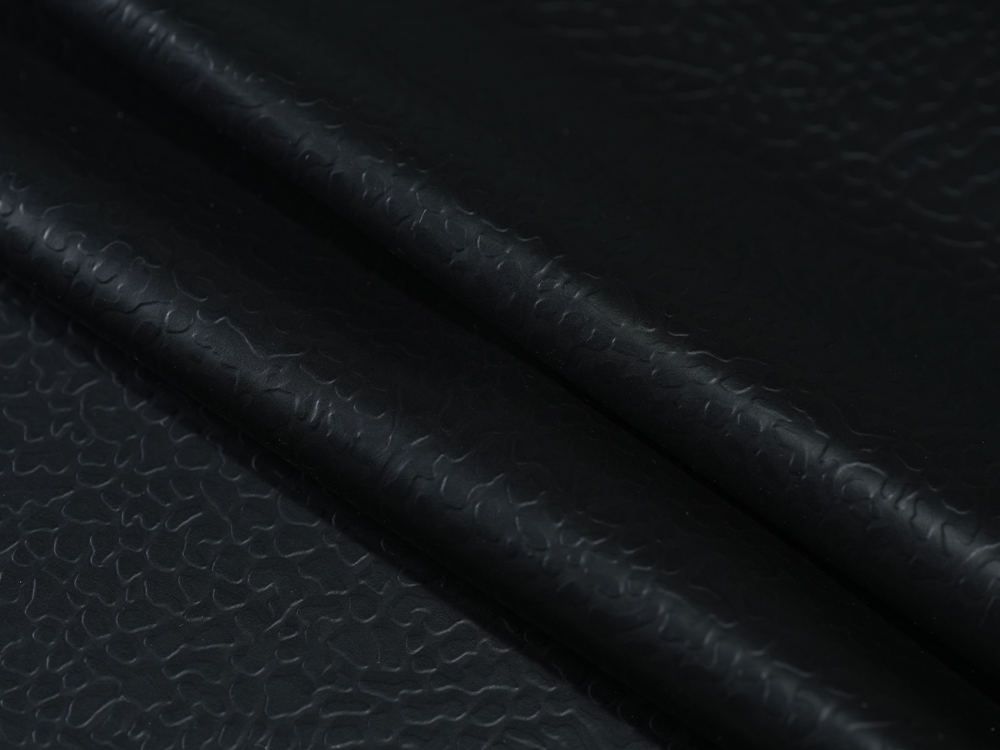

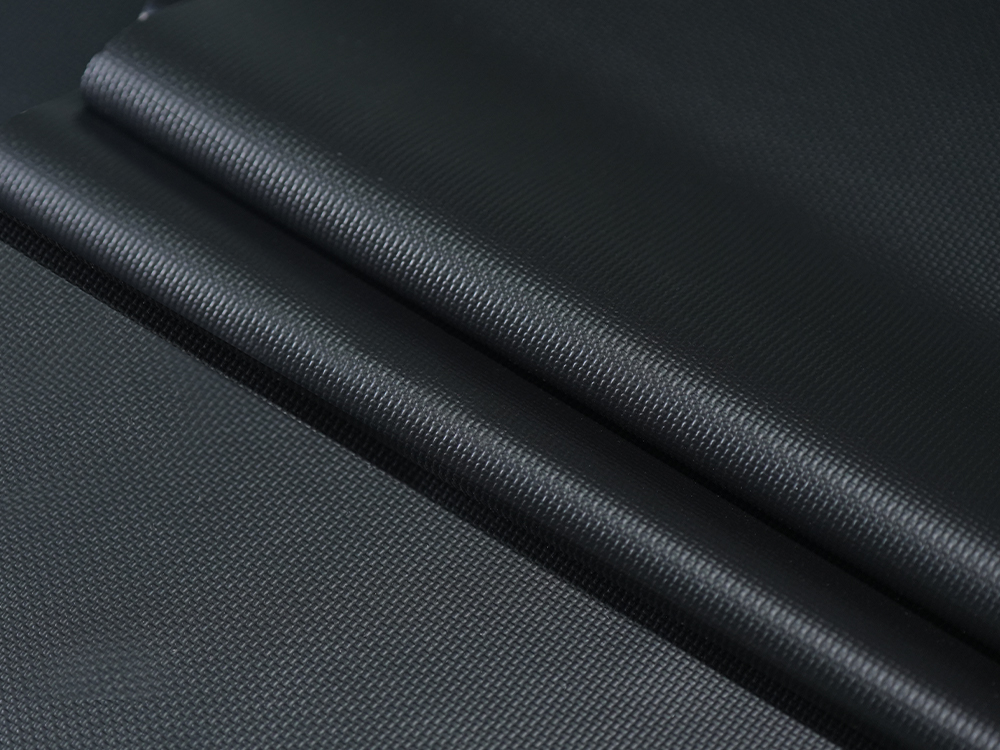

Semi matt release paper is a key material in synthetic leather, PU, and PVC coating processes. Its surface characteristics directly influence the quality of coated products. One of the critical aspects affecting performance is porosity, which determines the paper’s ability to manage air release and prevent defects such as bubbles or uneven surfaces. Understanding how semi matt release paper functions in this context is essential for manufacturers aiming to achieve consistent surface quality.

Anhui Honghuan New Material Technology Co., Ltd. is a leading manufacturer of high-temperature release paper for synthetic leather, specializing in semi matt release paper, coated paper, and other specialty packaging materials. Their experience in production, R&D, and after-sales service ensures reliable solutions for industrial applications.

The role of porosity in semi matte release paper

Porosity refers to the microscopic openings in semi matte release paper that allow air to pass through during coating or lamination processes. Proper porosity ensures that trapped air can escape efficiently, reducing the risk of air bubbles forming between the coating layer and the substrate.

Insufficient porosity can result in:

- Uneven coating thickness

- Localized surface defects

- Reduced adhesion and gloss consistency

Excessive porosity, on the other hand, may lead to:

- Ink or coating penetration

- Surface roughness issues

- Unintended texture formation

Hence, achieving the correct balance in porosity is critical for maintaining high-quality finishes.

How porosity affects air bubble prevention

In coating processes, air pockets can form when the release paper surface traps air between itself and the coated layer. Semi matt release paper with optimized porosity allows these air pockets to escape through microchannels, preventing defects. The semi-matte texture also contributes by controlling the distribution of coating materials, improving contact uniformity.

The following table summarizes the relationship between porosity levels and coating outcomes:

| Porosity Level | Air Bubble Formation | Coating Uniformity | Surface Smoothness |

|---|---|---|---|

| Low | High | Poor | Rough |

| Medium (Optimal) | Minimal | Good | Smooth |

| High | Low | Variable | Slightly Rough |

Semi matt release paper is engineered to maintain medium porosity, ensuring efficient air release while preserving surface integrity.

Material composition and manufacturing considerations

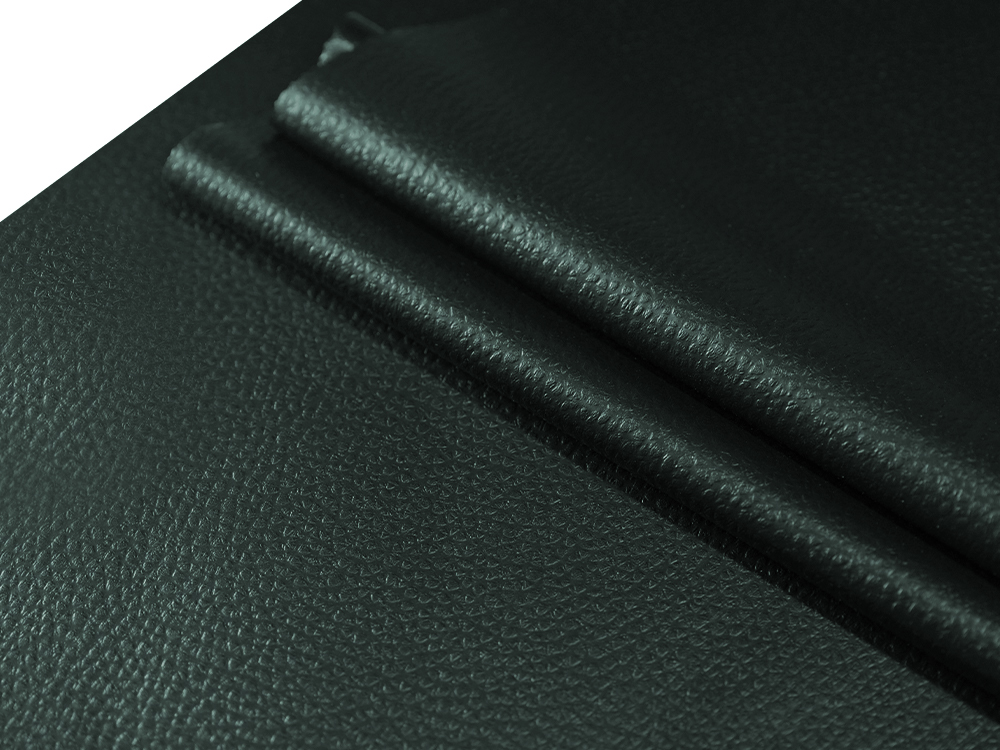

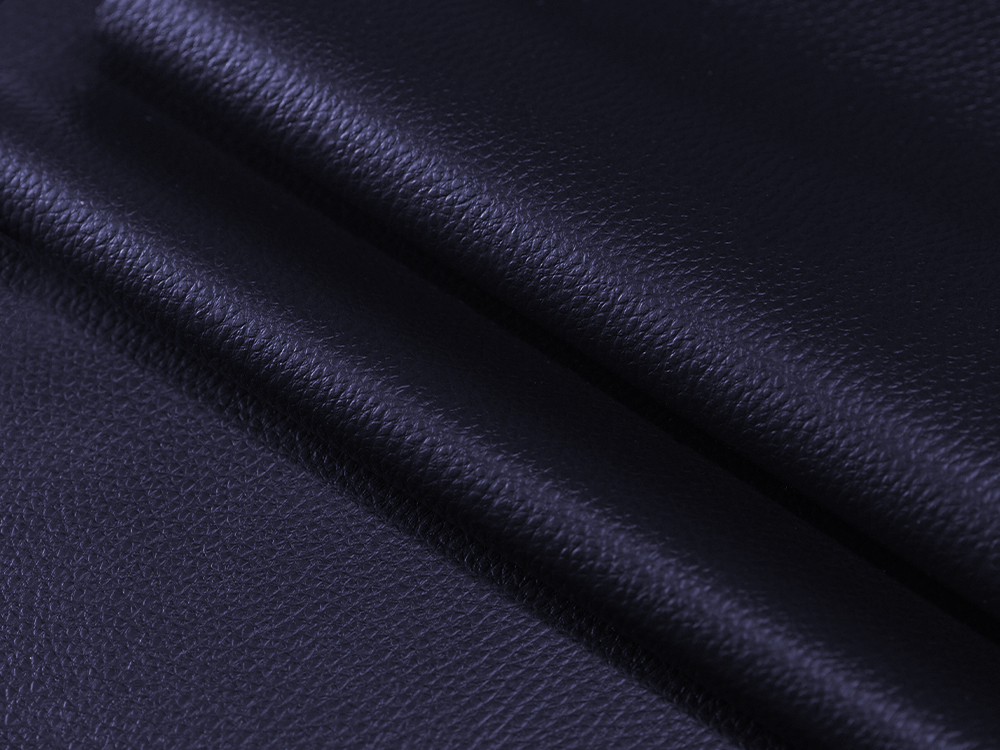

Semi matte release paper is typically produced using high-quality base paper combined with specialized release coatings. These coatings are designed to withstand high temperatures during PU or PVC processing without compromising the semi-matt texture. Key factors in manufacturing include:

- Base paper density: Determines structural support and moisture absorption.

- Release coating thickness: Influences adhesion and peel-off efficiency.

- Surface treatment: Micro-embossing or texture control affects both porosity and air release capability.

Anhui Honghuan New Material Technology Co., Ltd. has developed advanced production techniques to ensure consistent semi matt release paper quality. Their automated and semi-automated lines, supported by precise testing equipment, guarantee reliable porosity levels across large production batches.

Applications of semi matte release paper in coatings

Semi matt release paper is widely used in industries requiring high-quality surface finishes:

- Synthetic leather manufacturing – Prevents bubble formation during PU coating, ensuring a uniform, semi-matte finish.

- Floor leather production – Enhances surface smoothness and reduces defects caused by trapped air.

- Luggage and bag materials – Maintains durability and aesthetic appeal by controlling air release.

- Automotive interiors – Supports scratch-resistant and anti-fingerprint coatings by providing even adhesion.

By optimizing porosity, manufacturers can achieve improved product performance and reduce waste caused by surface defects.

Technical factors influencing porosity

Several technical parameters affect the porosity of semi matte release paper:

- Pore size distribution: Uniform micro-pores promote even air escape.

- Coating viscosity: Thick coatings may block pores if not properly controlled.

- Temperature resistance: High-temperature processes require paper that retains porosity under heat.

- Surface tension compatibility: Ensures coatings spread evenly without creating air traps.

Through R&D and testing, semi matte release paper can be engineered to balance these factors, resulting in consistent bubble-free coatings.

Quality control and testing

To ensure the effectiveness of semi matt release paper, manufacturers employ rigorous quality control methods:

- Porosity measurement: Determines air permeability and optimal bubble prevention.

- Surface roughness analysis: Confirms the semi-matte texture is consistent.

- Coating adhesion tests: Evaluates performance under PU or PVC lamination.

- Thermal stability checks: Ensures the paper withstands production temperatures without pore collapse.

Anhui Honghuan New Material Technology Co., Ltd. integrates pilot coating machines and analytical instruments in their production lines, supporting precise and reliable testing for high-quality output.

Choosing the right semi matt release paper

Selecting semi matt release paper depends on the specific production needs:

- Coating type – PU, PVC, or silicone-based coatings have different porosity requirements.

- Surface finish goal – Smooth, semi-matte, or embossed textures influence air release design.

- Process temperature – High-temperature applications demand thermally stable paper.

- Roll width and length – Production line compatibility and efficiency considerations.

Proper selection reduces defects, improves coating uniformity, and enhances overall production efficiency.

Advantages of semi matt release paper in bubble prevention

- Efficient air release prevents trapped air from forming bubbles.

- Consistent semi-matte surface enhances product appearance and tactile quality.

- High-temperature resistance ensures reliable performance in industrial coating processes.

- Customizable specifications allow tailoring for specific coating types and embossing designs.

These advantages make semi matt release paper a preferred solution for many manufacturers in the synthetic leather and specialty coating industries.

Conclusion

The porosity of semi matt release paper plays a pivotal role in preventing air bubbles during PU, PVC, and other coating applications. Properly engineered porosity enables smooth coating surfaces, enhances adhesion, and ensures product consistency. Manufacturers like Anhui Honghuan New Material Technology Co., Ltd. provide high-quality, high-temperature-resistant semi matt release paper with reliable performance, technical support, and flexible customization options, helping customers achieve efficient and defect-free production.

By understanding the relationship between porosity and air bubble prevention, producers can optimize their coating processes and deliver superior products across various industries.

FAQs about semi matt release paper

Q1: What industries commonly use semi matt release paper?

A1: Semi matt release paper is widely used in synthetic leather, floor leather, automotive interiors, luggage, and specialty coated materials.

Q2: How does semi matt release paper prevent air bubbles?

A2: Its controlled porosity allows trapped air to escape during coating, reducing defects and ensuring smooth surface finishes.

Q3: Can semi matt release paper be customized?

A3: Yes, it can be tailored for different gloss levels, embossing designs, roll widths, and coating types to meet specific production needs.

Q4: What technical factors affect its performance?

A4: Porosity, coating thickness, thermal resistance, surface tension compatibility, and surface texture all influence the performance of semi matt release paper.

Q5: What services are available from manufacturers?

A5: Manufacturers provide R&D, OEM/ODM customization, flexible scheduling, quality testing, and after-sales support to ensure consistent product performance.

English

English 中文简体

中文简体