Submit feedback

Custom Matte Release Paper Manufacturers

Industry Knowledge Extension

What role does Matte Release Paper play in PVC, PU, or silicone-based processes?

In modern synthetic material production, the use of matte release paper, also known in some applications as matt release paper or non-glossy release paper, has become increasingly important due to its ability to define surface characteristics, maintain dimensional precision, and stabilize production efficiency. PVC, PU, and silicone-based processes rely on consistent release performance, controlled surface texture, and stable thermal behavior to achieve high-quality finished products. In these industries, the surface matte level plays a crucial role in determining decorative attributes, wear resistance, and visual appeal.

The functional foundation of matte release paper in synthetic material production

The importance of controlled surface texture

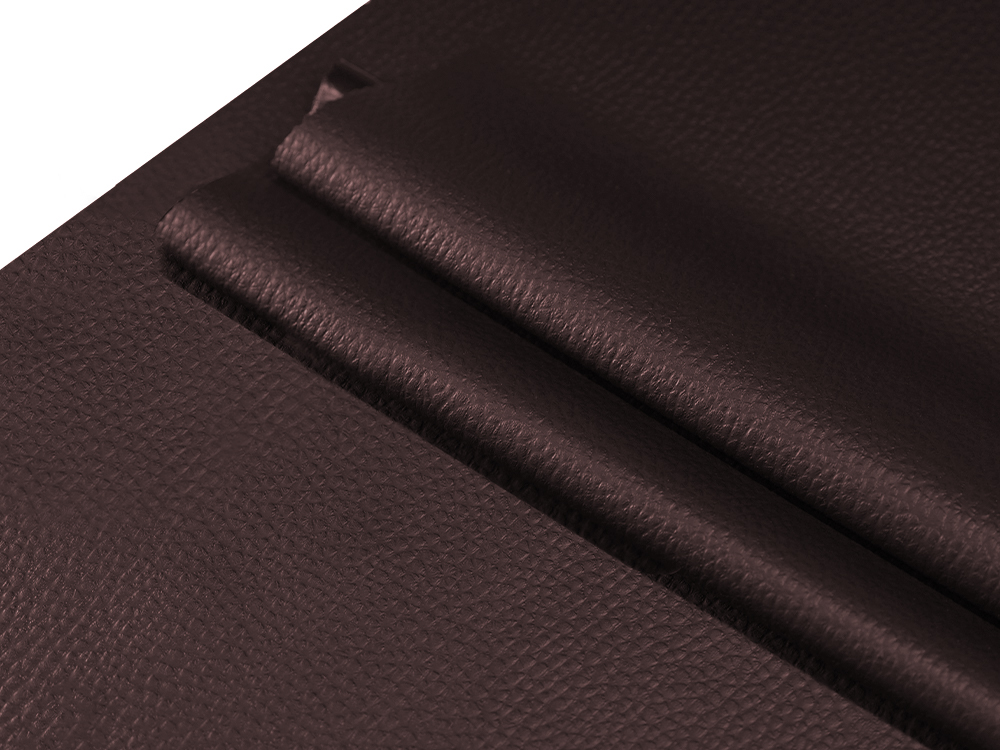

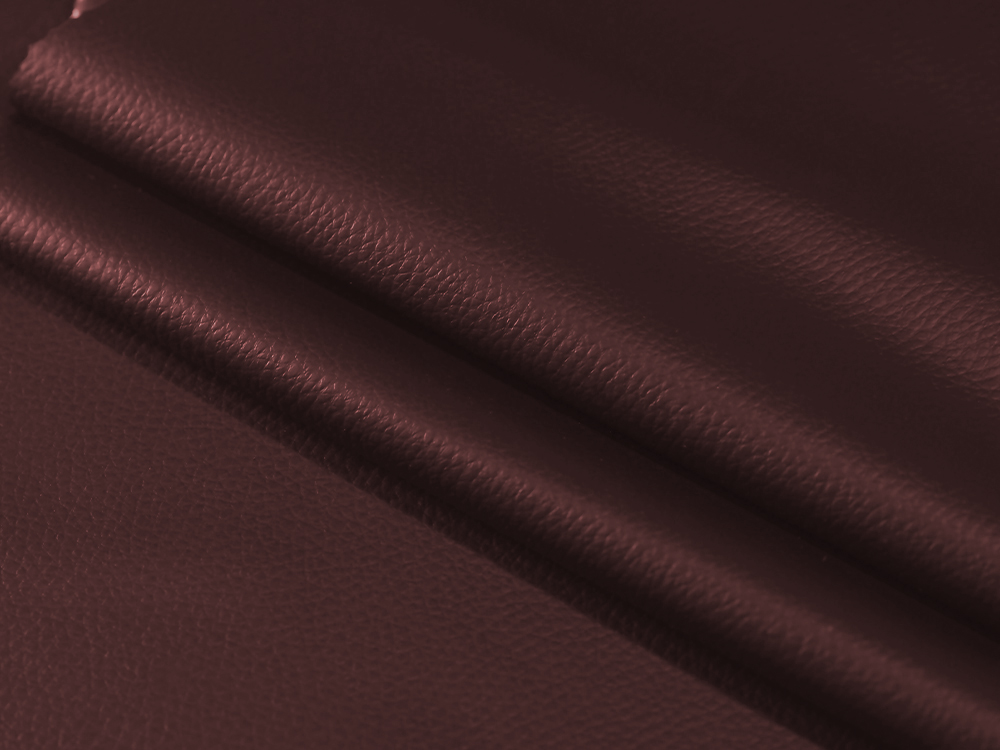

The primary purpose of matte release paper is to create a uniform non-gloss surface on PVC, PU, and silicone products. During the lamination or coating process, the material cures against the paper surface. The micro-roughness, texture depth, and coating formulation of the paper determine the final appearance of the finished sheet. Unlike gloss release grades, matte release paper provides a low-reflective, soft-touch effect that is widely demanded in applications such as upholstery, luggage leather, electronic device accessories, footwear materials, and industrial protective films.

Stability throughout thermal cycles

High temperatures are commonly involved in PVC and PU processing, particularly during calendaring, embedding, embossing, and curing. Silicone-based systems may also involve elevated curing temperatures to activate crosslinking. Because of these conditions, non-glossy release paper requires strong thermal resistance and low deformation characteristics. If dimensional stability is compromised, the printed pattern or matte texture can become distorted, affecting material uniformity. This is why producers rely on carefully formulated base papers and heat-stable coatings to maintain geometrical precision throughout repeated production cycles.

Release performance and demolding consistency

A key feature of matt release paper is its controlled release force. Too strong a release can damage the finished surface, while too light a release can lead to premature detachment, air pockets, or product warping. PVC and PU often require mid-level release strength, whereas silicone may adhere more aggressively without proper release coatings. By ensuring a stable separation from the substrate, matte release paper prevents defects such as surface tearing, gloss inconsistency, or coating transfer.

Material-specific roles of matte release paper

Matte release paper in PVC processing

Achieving uniform matte surfaces

PVC synthetic leather production commonly uses calendar rolling and coating processes. When the PVC resin layer is laminated onto matte release paper, it replicates the micro-texture of the paper surface. This results in controlled gloss levels, uniform grain density, and improved abrasion resistance. Such characteristics are essential for car interiors, furniture materials, and industrial sheet goods.

Improving mechanical stability

PVC is sensitive to temperature variation. Excessive heat can cause shrinkage, discoloration, or uneven curing. The dimensional stability of the non-glossy release paper helps reduce product warping and ensures consistent sheet thickness. This is particularly important in multilayer PVC systems where multiple coatings are added sequentially.

Enhancing production efficiency

By maintaining a consistent release force and stable matte texture, manufacturers can reduce adjustment frequency during production. Continuous operation without interruptions lowers waste rates and increases output quality.

Matte release paper in PU production

Supporting solvent-based and water-based PU systems

PU synthetic leather production involves either wet or dry methods, both requiring controlled curing. The micro-absorption characteristics of matte release paper influence solvent evaporation and moisture penetration. A stable matte base helps produce finer and more realistic leather textures.

Surface functionalization

Matte surface PU materials often require specific tactile attributes, such as soft-touch or anti-slip properties. The texture and coating layer on matt release paper directly determine these effects. By adjusting matte depth and micro-roughness, manufacturers can produce PU surfaces suitable for shoes, sofa materials, industrial belts, and protective gear.

Improving coating adhesion and layer uniformity

The stable surface energy of matte release paper ensures that PU coatings spread evenly before curing. This reduces surface defects such as fish eyes, pinholes, or texture inconsistency.

Matte release paper in silicone-based processes

Managing adhesion behavior

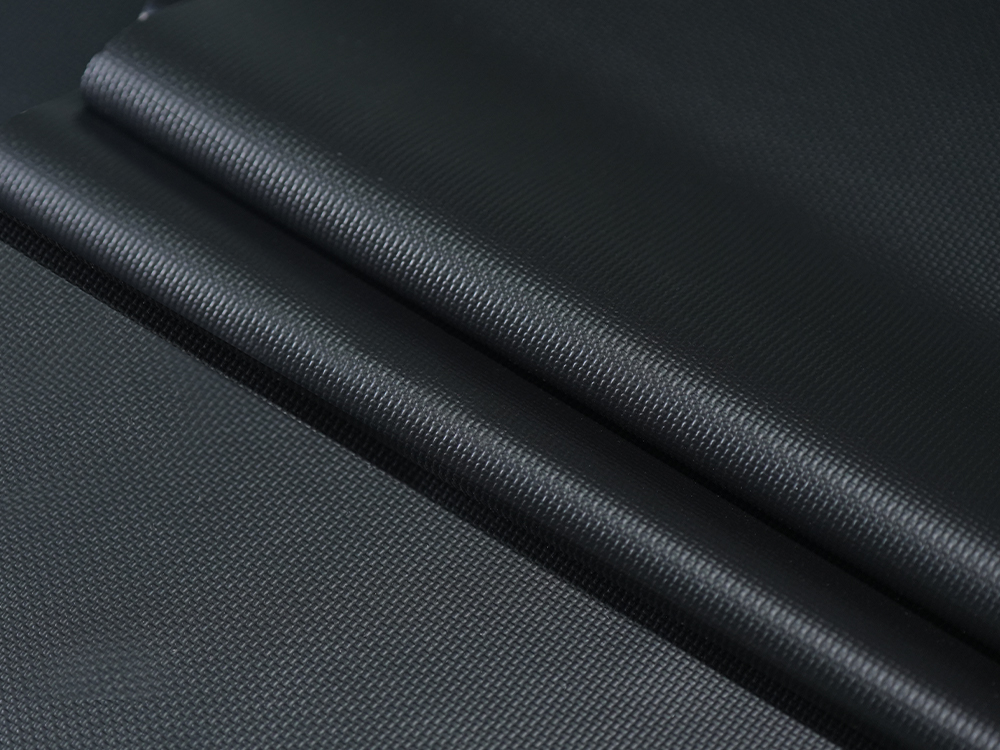

Silicone formulations often exhibit high stickiness. The release coating applied to matte release paper helps maintain predictable separation without damaging the finished product. This is critical when producing silicone sheets, tool grips, protective covers, and industrial insulators.

Maintaining matte consistency under heat

Silicone materials frequently require elevated temperatures to complete crosslinking. At these temperatures, low-quality release paper may deform. High-grade non-glossy release paper maintains its structure and matte pattern, ensuring consistent replication of surface characteristics.

High-performance visual and functional requirements

In silicone applications, matte surfaces offer benefits such as anti-glare performance, improved grip, and enhanced visual quality. Matte release paper defines these characteristics by acting as the surface mold during curing.

Company background and technical capacity (within your required 10%)

Production capabilities supporting matte release paper

Anhui Honghuan New Material Technology Co., Ltd. is a manufacturer specializing in high-temperature release paper for synthetic leather. With facilities located in Shitan Industrial Park in Anhui Province, the company integrates R&D, production, and sales. It operates two factories with automated and semi-automated production lines, enabling high output efficiency and flexible scheduling. The company’s annual investment, research capacity, and high-performance equipment—including pilot coating machines and analytical instruments—provide strong support for consistent matte release paper production.

Established by Kunshan FASTER New Materials Group with a total investment of RMB 300 million, the company covers 58 acres and maintains reliable access to transportation networks, enabling stable logistics and timely delivery. Equipped with a technical team specializing in leather release papers, the enterprise ensures precise quality control from design to final production. Width options range from 1,600 mm to 2,350 mm, with MOQs starting at 2,000 meters per roll, offering versatility for different customer requirements.

The company maintains a complete supply chain for base paper and chemical materials, ensuring uninterrupted production and stable performance even during periods of economic fluctuation. With OEM and ODM capabilities, the company supports development of custom matte levels and embossed patterns according to customer specifications.

Key performance characteristics influencing matte release paper selection

Surface uniformity and matte depth

Different industries require varying degrees of matte effect. Matte release paper must present consistent and defect-free texturing to reproduce the same appearance across entire production batches. Any inconsistency results in visible gloss variation.

Thermal resistance

Release paper used in PVC, PU, and silicone production must tolerate repeated heat cycles without shrinking or altering its surface.

Below is a table summarizing typical temperature ranges:

| Material system | Typical processing temperature | Required paper stability level |

|---|---|---|

| PVC | Medium to high | High |

| PU | Medium | Medium to high |

| Silicone | High | Very high |

Coating integrity

The release layer on matte release paper must withstand high shear forces and mechanical stress. Poor coating bonding can lead to transfer issues or surface damage on the finished material.

Dimensional precision

Warping or deformation can result in defective sheets, improper adhesion, or pattern distortion. High-quality release paper must maintain its structure over long production runs.

How matte release paper supports production efficiency

Consistency across batches

Reliability is crucial in large-scale PVC, PU, and silicone manufacturing. With stable matte textures and predictable release strength, matt release paper reduces the need for frequent machine adjustments. This leads to shorter production cycles and improved uniformity between batches.

Reduced error rates

Defects such as gloss inconsistency, uneven thickness, or coated layer tearing can cause large quantities of material loss. Non-glossy release paper helps prevent these issues through stable surface properties and controlled release behavior.

Lower maintenance needs

The durability of high-quality release paper reduces wear during repeated use. Production lines experience fewer shutdowns related to paper replacement, roller contamination, or surface damage.

Application-specific benefits

PVC synthetic leather and film materials

The replication of matte micro-textures ensures uniform surface quality in automotive interiors, floor coverings, luggage materials, and flexible sheets.

PU synthetic leather and specialty coatings

Matte release paper is used to achieve soft-touch textures, anti-slip surfaces, and visually appealing finishes for footwear, furniture, and consumer goods.

Silicone industrial and consumer materials

Products such as silicone membranes, protective skins, gaskets, and tool grips benefit from high-temperature matte release surfaces that improve handling and reduce glare.

Conclusion

Matte release paper plays a central role in shaping the surface characteristics, production quality, and efficiency of PVC, PU, and silicone-based materials. Its ability to provide consistent matte textures, maintain structural stability under heat, and deliver reliable release performance makes it indispensable in modern manufacturing. Whether applied to synthetic leather production, protective silicone parts, or decorative PVC sheets, matte release paper ensures uniformity, precision, and high-quality results.

FAQs about matte release paper

What is matte release paper used for?

It is used to replicate a matte texture onto PVC, PU, and silicone materials while enabling controlled release during demolding or curing.

How is matte release paper different from gloss release paper?

Matte release paper provides a low-reflective surface, while gloss grades offer a shiny finish. Each is selected based on desired visual effects.

Can matte release paper be reused?

Depending on the formulation and production conditions, some grades may support multiple uses, though this varies by application.

Does matte release paper affect the durability of synthetic leather?

Yes. The uniformity of the paper’s surface directly influences abrasion resistance and visual consistency.

What industries use matte release paper most frequently?

PVC leather producers, PU synthetic leather manufacturers, silicone sheet fabricators, and makers of decorative or industrial films commonly rely on matte release paper.

English

English 中文简体

中文简体