Submit feedback

How to Choose the Right PVC Leather Release Paper for Your Production Process?

In the intricate world of synthetic leather manufacturing, every component plays a pivotal role in determining the final product's quality, aesthetics, and durability. Among these, PVC leather release paper is a critical, yet often overlooked, element. This specialized paper is used during the calendaring or coating process to impart a specific surface texture—whether it's a sleek gloss, a natural grain, or an exotic pattern—onto the PVC leather. Choosing the incorrect release paper can lead to defects like poor texture transfer, sticking issues, or inconsistent finishes, ultimately impacting production efficiency and product value. This guide delves deep into the key factors you must consider to select the perfect release paper, ensuring your production process is optimized for both quality and cost-effectiveness. We will explore technical specifications, application-specific requirements, and practical handling considerations, seamlessly integrating insights related to essential long-tail search queries that professionals in this field are actively researching.

Understanding the Core Function and Types of PVC Leather Release Paper

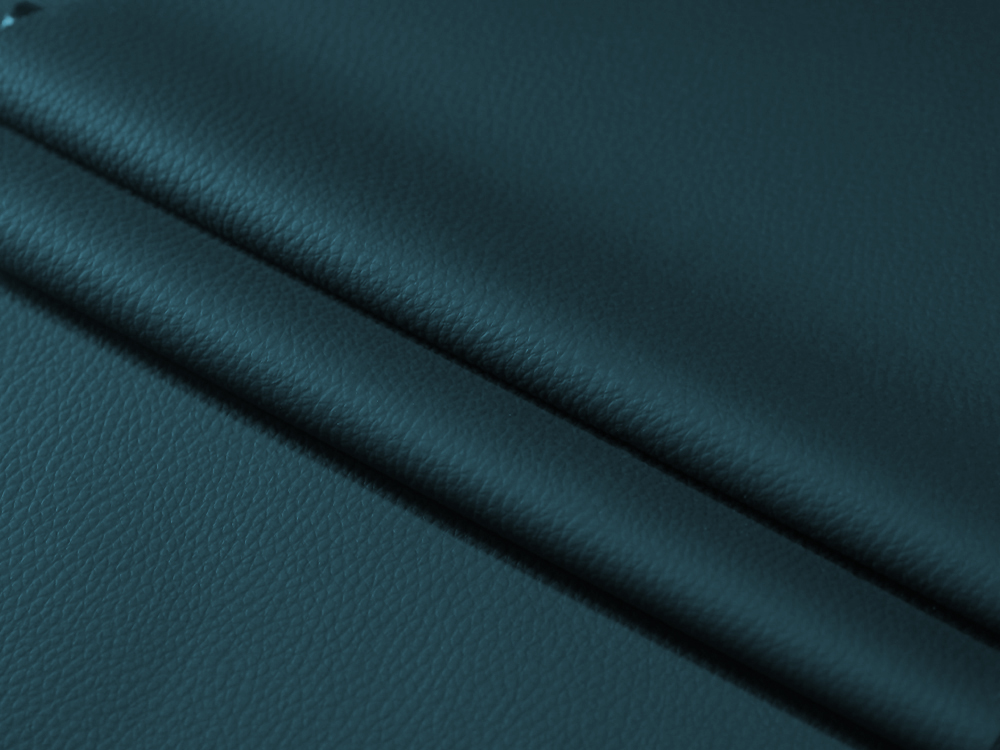

At its essence, PVC leather release paper acts as a temporary carrier and texturing mold. It is coated with a silicone layer that allows the PVC compound to be released cleanly after curing, while its surface pattern is permanently embossed onto the leather. The choice of paper directly dictates the visual and tactile appeal of the final product. The market offers a vast array of types, primarily categorized by their base material and surface treatment. The most common base is high-quality kraft paper, prized for its strength, stability, and smoothness, which is essential for achieving fine, consistent textures. Another critical type is what the industry often seeks as high gloss release paper for PVC leather, which undergoes additional calendaring and coating processes to create an exceptionally smooth, mirror-like surface. This type is indispensable for producing patent leathers, automotive interiors, and high-fashion items requiring a deep, reflective shine. Beyond gloss, papers are engineered to replicate crocodile, ostrich, geometric patterns, or traditional leather grains like full-grain or nubuck. Understanding this functional spectrum is the first step in aligning your paper choice with your desired end-product characteristics.

- Primary Function: Serves as a texturing medium and release agent during the PVC gelation and cooling phases.

- Base Material Importance: Kraft paper provides dimensional stability under heat and pressure, preventing stretching or tearing that could distort the pattern.

- Surface Finishes: Ranges from matte and semi-gloss to high gloss; each finish requires precise silicone coating levels for optimal release.

- Pattern Depth and Definition: Papers vary in engraving depth. Deep grains require papers with robust construction to hold the pattern under high pressure.

- Reusability Factor: While some papers are designed for single use, higher-quality ones can be reused multiple times (often 3-8 cycles), impacting long-term cost calculations.

Key Technical Specifications to Evaluate

Selecting release paper goes beyond just picking a pattern. Several technical parameters critically influence performance on your production line. Ignoring these can result in operational headaches. First, grammage and thickness are fundamental. Grammage (measured in g/m²) indicates the paper's density and weight. Heavier grammage papers (e.g., 90-120 gsm) offer superior toughness, heat resistance, and dimensional stability, making them suitable for high-pressure calendaring and multiple reuses. Thickness correlates with durability but also affects the sharpness of texture transfer; an overly thick paper might not conform perfectly to the embossing roller or plate. Secondly, heat resistance and thermal stability are non-negotiable. PVC processing involves temperatures typically between 150°C to 200°C. The paper must withstand this without scorching, losing tensile strength, or causing the silicone layer to degrade, which would lead to sticking. This is a core concern for queries like PVC leather release paper temperature resistance. Furthermore, the silicone coating weight and uniformity determine the release force—the ease with which the paper separates from the cured PVC. An uneven coating can cause partial sticking, tearing the paper or damaging the leather surface.

- Grammage (GSM): Opt for 90-120 gsm for heavy-duty, reusable applications; 70-90 gsm may suffice for single-use or lighter textures.

- Heat Resistance Threshold: Ensure the paper is rated for continuous use at least 20-30°C above your maximum process temperature.

- Silicone Release Force: Can be engineered as easy, medium, or tight release. Easy release is common but may not be suitable for very deep or intricate patterns where the PVC might shrink away prematurely.

- Tensile Strength and Elongation: High tensile strength (both machine and cross direction) prevents breaks during high-speed processing. Low elongation ensures the pattern does not distort.

- Moisture Content: Paper with high moisture content can steam and blister under heat, ruining the texture. It must be properly dried and stored in controlled conditions.

| Specification | Why It Matters | Typical Range/Consideration |

| Grammage | Determines durability, stability, and reuse potential. | 70-120 g/m² (gsm) |

| Heat Resistance | Prevents scorching, degradation, and sticking at high temps. | > 200°C continuous exposure |

| Silicone Coating Weight | Controls release force and affects surface finish clarity. | Light (easy release) to Heavy (tight release) |

| Tensile Strength (MD/CD) | Prevents breaks during machine tension and handling. | High values in both directions are critical. |

| Moisture Content | Affects flatness and prevents blistering under heat. | < 5% is ideal |

Matching Paper to Your Specific Production Application

The "right" paper is entirely contextual to your end product. A manufacturer producing embossed PVC leather for furniture has vastly different needs from one producing automotive dashboards or fashion handbags. For furniture applications, the emphasis is often on durable, natural-looking grains (like oak, walnut, or classic leather patterns) that feel authentic to the touch. The paper must be capable of creating a deep, consistent emboss that can withstand the wear and tear of daily use while hiding scratches. Here, factors like pattern depth and the paper's ability to handle potential plasticizer migration from the PVC compound become crucial. On the other hand, applications requiring a high gloss release paper for PVC leather demand an exceptionally smooth and flawless paper base. Any microscopic imperfection in the paper—a dust particle, a faint scratch—will be telegraphically transferred onto the leather surface, rendering it defective. This makes cleanliness and surface perfection the top priority for gloss papers. Furthermore, for those investigating release paper for synthetic leather manufacturing in a broader sense, it's vital to consider the compatibility with the specific PVC formulation, including the type and amount of plasticizers, stabilizers, and fillers used, as these can interact with the silicone release layer.

- Furniture & Upholstery: Focus on deep, robust grain patterns, excellent heat resistance for longer curing cycles, and good anti-stick properties even with soft, highly plasticized compounds.

- Automotive Interiors: Requires papers that produce consistent, premium textures (often finer grains or precise geometric patterns) with high durability and resistance to causing odor or fogging.

- Fashion & Accessories: Demands high versatility—from exotic animal prints to smooth glosses. Paper must enable sharp pattern definition and often involves smaller batch runs with frequent pattern changes.

- Footwear: Needs papers that provide good texture while allowing for subsequent processing like bonding, stitching, and flexing without texture cracking.

- General Manufacturing Tip: Always request sample rolls to test the paper on your specific production line with your exact PVC formulation before bulk ordering.

Cost Considerations and Sourcing Tips

Budget is always a constraint, but with release paper, the cheapest option often becomes the most expensive due to production losses. A holistic view of cost includes not just the price per square meter, but also the cost-in-use, which encompasses reuse potential, defect rate, and machine downtime. Papers designed for multiple uses PVC leather release paper may have a higher upfront cost but can dramatically reduce the cost per meter of produced leather over 5-10 cycles. Calculating the break-even point is essential. Sourcing requires diligence. It's advisable to work with suppliers who provide comprehensive technical data sheets (TDS) and are transparent about the paper's origins and specifications. Be wary of generic claims. For instance, a query like where to buy PVC leather release paper should lead you to specialized industrial paper converters or manufacturers with proven expertise in synthetic leather applications, not general stationery suppliers. Establish a relationship with a supplier who offers technical support, can guarantee consistency across batches, and understands the challenges of synthetic leather manufacturing processes.

- Total Cost of Ownership (TCO): Calculate: (Paper Cost per Roll / Number of Use Cycles) + (Cost of Defects & Downtime).

- Reuse Cycle Testing: Conduct internal tests to verify the supplier's claimed reuse cycles under your specific factory conditions.

- Minimum Order Quantity (MOQ): Balance inventory costs. For testing new patterns, seek suppliers with lower MOQs for sample rolls.

- Supplier Qualification: Prioritize suppliers with ISO certifications, robust R&D capabilities, and a portfolio of proven papers for your industry segment.

- Logistics & Storage: Factor in shipping costs and ensure you have a dry, temperature-controlled storage area to preserve paper quality before use.

Handling, Storage, and Best Practices for Optimal Results

Even the best PVC leather release paper can fail if mishandled. Proper practices from warehouse to production line are paramount to protect your investment and ensure consistent quality. Storage is the first critical step. Paper is hygroscopic, meaning it absorbs moisture from the air. Storing it in a humid environment will increase its moisture content, leading to issues like wrinkling, reduced tensile strength, and steam pockets forming during heating, which create blisters on the leather surface. Always store rolls vertically on their ends in a cool, dry place (ideally 20-25°C and 50% RH), wrapped in the original plastic packaging until ready for use. On the production floor, handling requires care to avoid edge damage, core crushing, or introducing creases. When mounting the roll onto the machine, ensure it is aligned correctly to prevent lateral tension that can cause web breaks. Furthermore, understanding the temperature resistance limits is not just for selection but for operation; gradually bringing the paper up to temperature in the machine can prevent thermal shock. After use, if the paper is intended for reuse, it should be carefully rewound, inspected for damage or contamination, and stored properly again.

- Storage Environment: Mandatory temperature and humidity control. Use dehumidifiers if necessary.

- Handling Procedures: Use proper lifting equipment for large rolls; never roll them on their edges. Always handle with clean, dry gloves to prevent oil and sweat transfer.

- Machine Preparation: Ensure all rollers and guides are clean, smooth, and properly aligned before threading the paper.

- Tension Control: Set appropriate unwinding and rewinding tensions according to the paper's grammage and supplier recommendations to avoid stretching or breaking.

- Post-Use Inspection: For reusable paper, establish a checklist: check for silicone layer integrity, surface contamination, edge tears, and overall flatness before approving for another cycle.

FAQ

What is the typical temperature range for PVC leather release paper during processing?

The processing temperature for PVC leather release paper is a critical parameter directly tied to the PVC compound's gelation and curing cycle. Typically, the paper must withstand temperatures between **150°C to 200°C (302°F to 392°F)**. The exact point within this range depends on your specific formulation and production speed. For instance, thicker coatings or compounds with higher filler content may require longer exposure at the higher end of this range to fully cure. It is a best practice, and a common search around PVC leather release paper temperature resistance, to select a paper rated for continuous use at least 20-30°C above your maximum process temperature. This safety margin accounts for potential hot spots in your calender or oven and ensures the paper's silicone coating does not degrade, which is the primary cause of sticking and paper tearing. Always consult the paper's technical data sheet for its maximum continuous and peak temperature ratings.

Can PVC leather release paper be reused, and how many times?

Yes, many types of PVC leather release paper are designed for reuse, which is a significant factor in managing production costs. This is precisely why professionals search for multiple uses PVC leather release paper. The number of possible reuse cycles varies widely, typically from **3 to 8 times**, depending on several factors:

- Paper Quality: Higher grammage, better base paper, and more durable silicone coatings directly increase reuse potential.

- Process Conditions: Higher temperatures and pressures, abrasive compounds (e.g., with certain fillers), or aggressive release agents can reduce paper life.

- Pattern Type: Deep, intricate patterns experience more mechanical stress and may wear out faster than shallow, smooth patterns.

- Handling and Cleaning: Careful rewinding, proper storage, and gentle cleaning (if applicable) between cycles can extend lifespan.

It's essential to monitor the paper closely after each cycle. Decreased release performance, visible wear on the pattern, surface scratches, or edge damage are clear indicators that the paper should be retired to prevent defects in your leather.

What's the difference between paper for matte finish and high gloss PVC leather?

The difference is profound and lies in the surface engineering of the paper itself. For a **matte or grained finish**, the paper has a physically textured or patterned surface that is transferred onto the PVC. The focus is on the precision and depth of this engraving. In contrast, high gloss release paper for PVC leather has an impeccably smooth, mirror-like surface. Its silicone coating is formulated and applied to create an ultra-low surface energy, allowing for a flawless release that leaves the PVC surface perfectly smooth and highly reflective. Any microscopic pit, scratch, or dust particle on the gloss paper will result in a corresponding defect on the leather, making cleanliness and surface perfection the paramount concerns. Furthermore, the release force for gloss papers is often finely tuned to be "easy" but not so easy that the PVC separates before it has fully set, which could cause shrinkage or gloss variation.

How do I prevent the release paper from sticking to my PVC leather?

Sticking is a common and costly issue, often stemming from an incompatibility between the paper and the process. Prevention is multi-faceted:

- Correct Silicone Release Force: Ensure the paper's release force (easy, medium, tight) matches your compound and process. An overly tight release or degraded coating will cause sticking.

- Respect Temperature Limits: Exceeding the paper's temperature resistance will break down the silicone layer, causing it to fuse with the PVC.

- Compound Formulation: Certain plasticizers, stabilizers, or lubricants in your PVC mix can migrate and interfere with the release layer. Test compatibility.

- Cooling Before Release: Ensure the laminated material is adequately cooled before the paper is stripped off. PVC that is too soft and hot will tend to stick.

- Machine Alignment and Tension: Uneven tension can cause the paper to wrinkle or crease, creating areas of increased pressure and potential sticking.

If sticking occurs, systematically review these factors, starting with a check of actual process temperatures versus the paper's rating.

Where can I find reliable suppliers for different types of release paper?

Finding a reliable supplier is as crucial as selecting the paper itself. Searches like where to buy PVC leather release paper should be directed towards industry-specific channels. The most reliable suppliers are typically:

- Specialized Industrial Paper Converters: Companies that focus on coating and treating papers for release applications in textiles, composites, and synthetic materials.

- Manufacturers with a Focus on Synthetic Leather: Some large paper mills have dedicated product lines for the synthetic leather manufacturing sector and offer extensive technical support.

- Industry Trade Shows: Events for the leather, plastics, and converting industries are excellent places to meet multiple suppliers, see samples, and discuss technical needs.

- B2B Industrial Platforms: Reputable global platforms can connect you with verified manufacturers, but due diligence is required—always request samples and TDS before committing.

Key supplier vetting questions should cover: consistency between batches, ability to provide technical data, sample availability, and their experience with your specific application (e.g., embossed PVC leather for furniture vs. automotive).

Copyright © Anhui Honghuan New Material Technology Co., Ltd. Rights Reserved.

Custom Casting Release Paper Factory

English

English 中文简体

中文简体