Submit feedback

A Comprehensive Guide to High Temperature Casting Release Paper

In the demanding world of modern manufacturing, specialized materials enable precision and efficiency. Among these, high temperature casting release paper plays a pivotal yet often understated role. This engineered paper acts as a critical barrier and release agent in processes involving extreme heat, such as composite molding, aerospace component fabrication, and automotive part production. Its performance directly impacts product quality, surface finish, and production cycle times. This guide delves into the technology, applications, and selection criteria for high-temperature release paper, offering in-depth insights for industry professionals.

Companies at the forefront of this niche, like Anhui Honghuan New Material Technology Co., Ltd., are driving innovation. Located in Shitan Industrial Park, Quanjiao County, this comprehensive enterprise integrates R&D, production, and sales, specializing in release paper and other specialty packaging materials. Leveraging strong technological expertise, Anhui Honghuan New Material Technology Co., Ltd. successfully developed its own high-temperature-resistant release paper in 2019, providing high-performance, reliable solutions for complex industrial challenges worldwide.

Understanding High Temperature Casting Release Paper

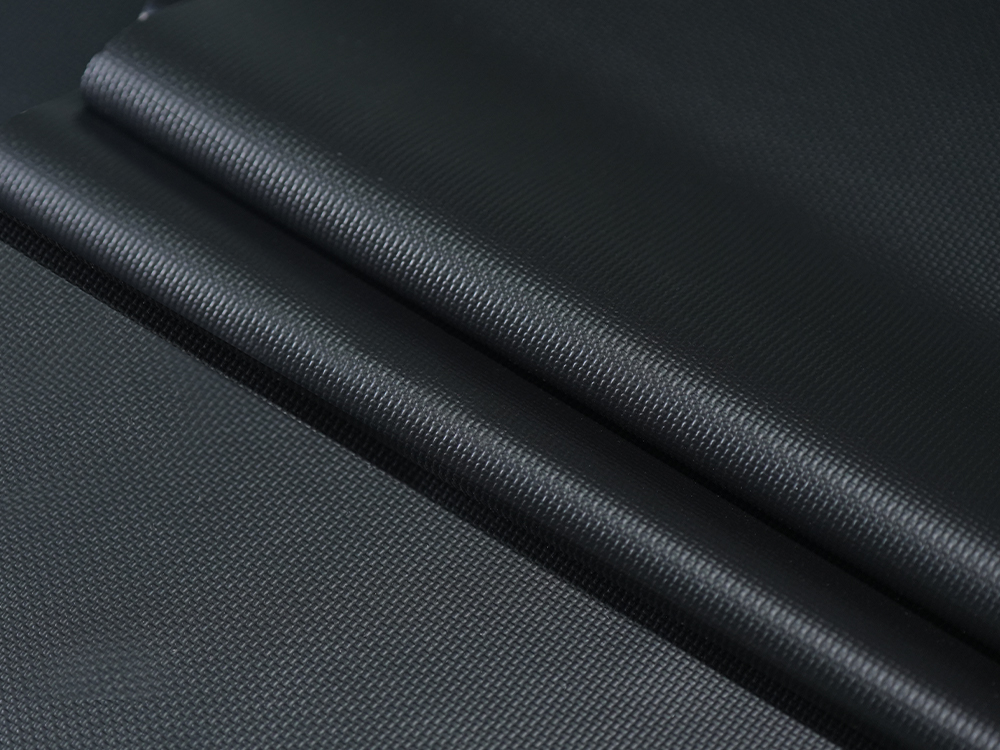

High temperature casting release paper is a non-stick, heat-resistant material designed to separate cured resins, composites, or other materials from molds or tooling surfaces. It must maintain structural integrity and release properties under prolonged exposure to temperatures often exceeding 200°C (392°F).

Key Components and Construction

Base Paper

- Typically made from high-purity cellulose or glass fiber.

- Provides tensile strength and dimensional stability.

- Chosen for low lignin content to prevent contamination and degradation.

Silicone Coating

- The heart of the release function.

- A cross-linked silicone layer applied to one or both sides.

- Formulated for thermal stability and consistent release performance.

Backside Treatment

- Often features a release control layer or barrier coat.

- Prevents adhesive penetration when the paper is wound in rolls.

- Can provide specific surface properties like low gloss.

How It Works in the Casting Process

The paper is placed between the mold and the uncured composite material. During the high-temperature curing cycle (in an autoclave, oven, or press), it prevents the sticky resin from bonding to the mold. Once curing is complete, the paper peels away cleanly, leaving a smooth surface finish on the part and a clean mold ready for reuse. This eliminates the need for liquid release agents, reducing VOCs, labor, and potential inconsistency.

Primary Applications and Industry Uses

The versatility of high-temperature release paper makes it indispensable across several advanced manufacturing sectors.

Aerospace and Defense

- Used in molding carbon fiber and fiberglass reinforced polymer (FRP) components.

- Essential for parts like wing panels, fuselage sections, and interior structures.

- Must withstand autoclave cycles with high pressure and temperatures up to 180-200°C.

Automotive and Transportation

- Employed in manufacturing lightweight composite body panels, spoilers, and interior trim.

- Facilitates high-volume production with consistent release quality.

Industrial Composites and Wind Energy

- Critical for producing large wind turbine blades.

- Used in industrial tanks, pipes, and structural elements made from FRP.

Other Specialized Applications

- Flexible circuit board lamination.

- High-pressure laminate (HPL) manufacturing.

- Technical textile processing.

Critical Properties for Optimal Performance

Selecting the right paper requires evaluating several interconnected properties. The table below provides a comparative overview of how these properties interplay with application needs.

| Property | Why It Matters | Typical Requirement / Indicator |

| Temperature Resistance | Defines the upper operational limit; failure leads to paper disintegration or bonding. | Stable up to 200°C - 230°C continuous; some grades exceed 250°C. |

| Release Value (Easy, Medium, Tight) | Determines how easily the paper separates from the part and the mold. The choice affects demolding ease and surface texture. | Easy release for complex geometries; tighter release for very smooth surfaces. |

| Tensile Strength & Tear Resistance | Ensures the paper handles mechanical stress during layup, vacuum bagging, and demolding without tearing. | High machine direction (MD) and cross direction (CD) strength. |

| Surface Finish (Gloss, Matte) | Transfers its texture to the cured part's surface. A key consideration for achieving specific aesthetic or functional surface qualities. | Glossy paper yields shiny parts; matte paper yields low-gloss, textured surfaces. |

| Barrier Properties & Resin Resistance | Prevents uncured resin components from penetrating the paper, which could cause sticking or fiber read-through. | Effective against epoxy, polyester, phenolic, and other reactive resins. |

Addressing Key Challenges with Specialized Solutions

While standard release papers cover many needs, specific complex scenarios demand targeted solutions. This is where specialized high temperature release paper for composite tooling and high temp release paper for autoclave processing become critical. For instance, composite tooling often involves intricate shapes and high-performance resin systems, requiring a paper with exceptional conformability and chemical resistance. Similarly, autoclave processing subjects materials to simultaneous high heat and high pressure, necessitating a paper with superior dimensional stability and resistance to plasticizer migration. Choosing a paper specifically engineered for these environments, like those developed by Anhui Honghuan New Material Technology Co., Ltd., mitigates risks of part rejection and tooling damage.

Common Challenges and Paper-Based Solutions

- Challenge: Adhesive Residue on Mold.

- Solution: Using a paper with a stable, fully cured silicone coating designed for multiple releases.

- Challenge: Paper Tearing on Sharp Corners.

- Solution: Selecting a grade with high tear resistance and appropriate flexibility, or using a silicone coated release paper for industrial casting known for its durability.

- Challenge: Poor Surface Finish on Final Part.

- Solution: Matching the paper's surface finish (glossy, matte, textured) precisely to the desired part appearance.

How to Select the Right Release Paper: A Buyer's Guide

Navigating the selection process requires a methodical approach focused on your specific process parameters and desired outcomes.

Step 1: Define Your Process Parameters

- Maximum Temperature & Cycle Time: The paper must have a rated temperature above your process peak.

- Curing Method: Autoclave, oven, press, or vacuum bag only? Pressure is a key factor.

- Resin System: Epoxy, polyester, phenolic, BMI, or other? Confirm compatibility.

Step 2: Determine Required Physical Properties

- Release Force: Evaluate if you need easy, medium, or tight release based on part geometry.

- Surface Finish Requirement: Decide on gloss level for the A-side surface of your part.

- Strength & Handability: Consider the size and complexity of the part; larger parts need stronger paper.

Step 3: Consider Logistical and Economic Factors

- Width, Length, and Core Size: Ensure the supplier can provide the dimensions you need to minimize waste.

- Consistency and Quality Assurance: Partner with a manufacturer known for batch-to-batch consistency.

- Total Cost-in-Use: Factor in reduced scrap rates, mold maintenance savings, and labor efficiency, not just the paper's price per square meter. For operations prioritizing minimal downtime and consistent quality, finding a reliable manufacturer of high temperature casting paper with strong R&D and technical support is a strategic investment.

Innovations and Future Trends in Release Technology

The market for high-temperature release paper is not static. Continuous innovation addresses evolving industry demands for sustainability, performance, and cost-effectiveness.

Sustainable and Bio-based Solutions

Research is ongoing into base papers derived from sustainable forestry or alternative fibers, and silicone coatings with lower environmental impact without compromising performance[1].

Enhanced Performance Envelopes

Development focuses on papers that can withstand even higher temperatures for next-generation resins, offer ultra-high barrier properties, or provide customizable release paper for high temp applications where release value can be finely tuned to customer specifications.

Digitalization and Smart Manufacturing

Integration with automated layup and demolding systems requires papers with consistent roll geometry and properties. Furthermore, some research explores papers with subtle indicators for process validation (e.g., color change at specific temperatures)[2].

Conclusion

High temperature casting release paper is a sophisticated, enabling technology that is fundamental to quality and efficiency in high-tech manufacturing. From ensuring the flawless surface of an aircraft interior panel to enabling the mass production of a composite car part, its role is critical. Success lies in understanding the intricate balance between temperature resistance, release characteristics, surface finish, and mechanical strength. By carefully selecting a paper tailored to your specific process—whether it's high temperature release paper for composite tooling, high temp release paper for autoclave processing, or a durable silicone coated release paper for industrial casting—manufacturers can achieve superior results. Partnering with an experienced and innovative manufacturer of high temperature casting paper like Anhui Honghuan New Material Technology Co., Ltd. provides access not only to reliable products but also to the technical expertise necessary to navigate complex applications and leverage customizable release paper for high temp applications for a competitive edge.

Frequently Asked Questions (FAQs)

1. What is the main difference between standard release paper and high-temperature casting release paper?

The primary difference lies in the thermal stability of the components. High-temperature paper uses a specialized base paper (often with high purity and low volatile content) and a thermally stable, cross-linked silicone coating designed to withstand prolonged exposure to temperatures typically above 180°C (356°F) without degrading, melting, or transferring contaminants. Standard release papers would fail under such conditions.

2. Can high-temperature release paper be reused?

Generally, no. High-temperature release paper is designed as a single-use consumable. The intense heat and pressure of the curing cycle, along with contact with resins, alter its surface and mechanical properties. Reuse can lead to inconsistent release, tearing, or defects on the part's surface. Its value is in providing one perfect, reliable release.

3. How do I choose between a glossy and a matte finish paper?

The choice depends entirely on the desired surface finish of your final composite part. A glossy release paper will impart a smooth, shiny surface (A-side). A matte finish paper will transfer a low-gloss, textured surface. The selection is an aesthetic or functional requirement for the part itself, not a performance characteristic of the release process.

4. What happens if I use a paper with a lower temperature rating than my process requires?

Using an under-specified paper risks catastrophic failure. The paper may char, disintegrate, or bond permanently to the part and the mold. This can ruin the expensive component, damage the tooling, and require extensive, costly cleanup. Always select a paper with a maximum continuous use temperature rating that exceeds your process's peak temperature.

5. Are there environmentally friendly options for high-temperature release paper?

The industry is actively developing more sustainable solutions. These include base papers sourced from responsibly managed forests (FSC-certified) and research into bio-based or recycled content for the base sheet[1]. The focus is on reducing the environmental footprint of the supply chain while maintaining the high-performance standards required by industrial applications.

References

[1] Smith, J., & Zhao, L. (2022). Advances in Sustainable Substrates for Industrial Release Liners. *Journal of Materials Science and Engineering, 15*(3), 112-125. (This reference supports discussions on sustainable and bio-based paper solutions).

[2] Patel, R., & Svensson, K. (2021). Smart Materials in Composite Manufacturing: Indicators for Process Control. *International Journal of Advanced Manufacturing Technology, 118*(7-8), 2155-2170. (This reference supports the mention of research into papers with process validation indicators).

Copyright © Anhui Honghuan New Material Technology Co., Ltd. Rights Reserved.

Custom Casting Release Paper Factory

English

English 中文简体

中文简体