Submit feedback

How to Choose the Right Release Paper for Artificial Leather Applications?

Understanding Release Papers in Artificial Leather Manufacturing

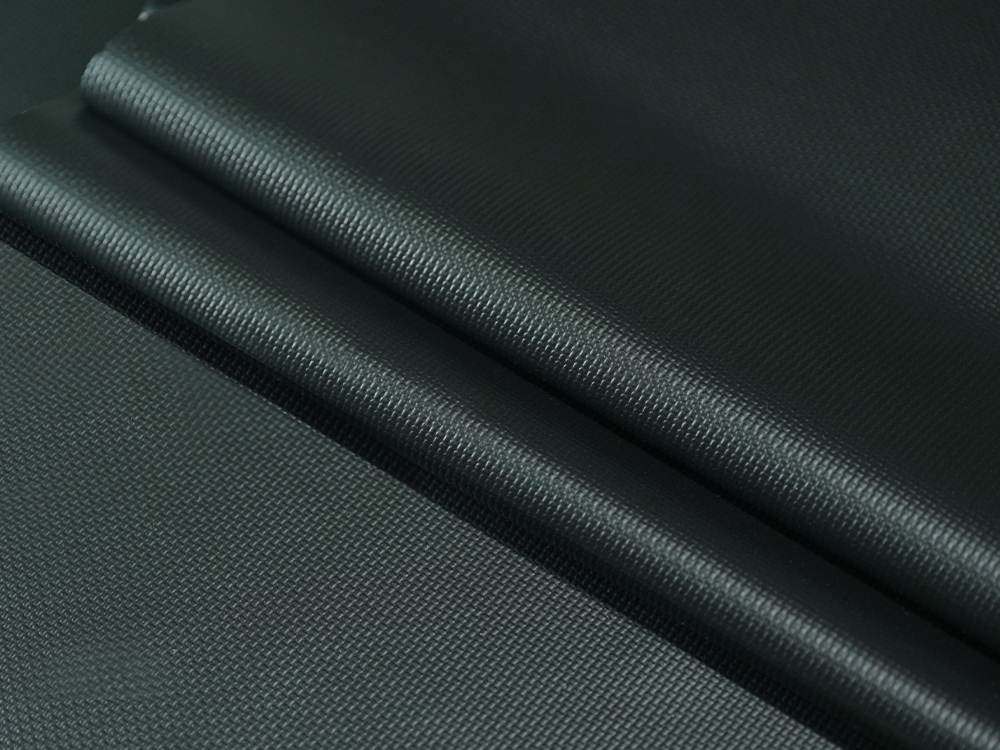

The production of high-quality artificial leather is a sophisticated process that relies heavily on the often-overlooked component: the release paper. This specialized paper acts as a temporary carrier and imprinting tool during the coating and curing stages. It imparts the desired surface texture, gloss, and pattern onto the polymer resin, which forms the grain layer of the artificial leather. Once the resin has solidified, the release paper is peeled away, leaving a perfectly textured surface behind. The selection of the appropriate release paper is not a trivial matter; it is a critical decision that directly influences the aesthetics, tactile properties, consistency, and ultimately, the commercial value of the final synthetic leather product. A poor choice can lead to defects like incomplete release, pattern transfer issues, or inconsistent texture across batches, resulting in significant material waste and production downtime. Therefore, mastering the selection criteria is paramount for anyone involved in the specification, purchasing, or production management within this industry. This article delves into the key technical and practical considerations, helping you navigate the complexities and make informed decisions that align with your specific product goals and manufacturing constraints.

Five Key Factors for Selecting Your Artificial Leather Release Paper

Choosing the ideal release paper involves balancing several interconnected factors. Focusing on five core areas will provide a structured framework for evaluation. Each factor addresses a specific aspect of performance and outcome, and understanding their interplay is essential. For instance, the desired final product aesthetics will dictate the necessary surface finish of the paper, which in turn may influence its durability and release characteristics. Similarly, the chemical composition of your coating formula must be compatible with the paper's release layer to prevent adverse reactions. By systematically considering the release paper texture types for synthetic leather grain, the silicone coated vs non-silicone release paper for PU leather, the specific requirements for release paper in embossed artificial leather, the critical aspect of heat resistance and durability of transfer paper for leather finishing, and the operational variable of how release paper weight affects artificial leather production speed, you can develop a comprehensive specification that minimizes risk and optimizes results. The following sections will expand on each of these pivotal long-tail keywords, providing the depth of knowledge needed for effective selection.

1. Analyzing Surface Finish: Release Paper Texture Types for Synthetic Leather Grain

The primary function of release paper is to transfer its surface topography onto the artificial leather. Therefore, the texture is the most visually and tactilely apparent factor in your selection. The range of available textures is vast, from perfectly smooth and glossy finishes to coarse, natural-looking grains, intricate geometric patterns, and lifelike reproductions of exotic animal hides. The choice fundamentally defines the product's market segment—a smooth, high-gloss paper might be used for futuristic fashion items or automotive interiors requiring a sleek look, while a deep, pronounced grain mimics traditional full-grain bovine leather for footwear and upholstery. It is crucial to understand that the texture is not merely a 2D pattern but a three-dimensional structure with depth, peak sharpness, and valley configurations. These microscopic details affect light reflection (gloss level), stain resistance (smoother surfaces are easier to clean), and the perceived hand-feel of the final product.

When evaluating textures, consider both aesthetic goals and practical production implications. A very deep and complex grain might require a heavier coating weight to fully fill the cavities, potentially increasing material costs. It may also pose challenges during the release (demolding) process if the undercuts are severe. Conversely, a very fine, shallow texture might release easily but could be more susceptible to showing coating inconsistencies or flow marks. Furthermore, the longevity of the paper's texture over multiple production runs is a key economic consideration. A robust texture that maintains its definition over dozens of cycles is more cost-effective than one that flattens out quickly. The selection process often involves reviewing physical sample books from paper manufacturers and conducting production trials to see how the texture performs with your specific resin system and process parameters. This hands-on evaluation is irreplaceable for ensuring the final product meets the desired aesthetic standard.

Common Texture Categories and Their Applications

To systematize the selection, textures can be grouped into broad categories. Each category serves distinct market applications and imparts unique characteristics to the artificial leather.

- Smooth/Glossy Finishes: These papers produce a uniform, reflective surface. Variants include mirror gloss, semi-gloss, and matte smooth finishes. They are often used for automotive dashboards, fashion accessories, electronic device coverings, and hygienic surfaces where cleanability is paramount. The lack of texture can make any subsurface imperfections in the coating more visible, demanding high-quality base fabrics and consistent coating application.

- Natural Leather Grains: This is the most extensive category, encompassing textures that replicate cowhide, goatskin, pigskin, ostrich, crocodile, and many others. The quality of replication varies greatly; premium papers offer incredibly authentic, non-repeating patterns with natural pore structures. These are the workhorses of the footwear, furniture, and apparel industries, where a classic leather look is desired.

- Embossed/Patterned Finishes: This includes geometric patterns (linen, checkerboard, diamond), artistic designs, and custom logos. These papers are used to create branded or stylized surfaces for fashion items, interior design elements, and specialty goods. The precision and sharpness of the pattern transfer are critical here.

- Napped/Suede Finishes: These papers have a delicate, directional texture used to create the soft, velvety surface of synthetic suede or nubuck. The process often involves a mechanical buffing of the coated surface after release, but the initial grain from the paper sets the foundation.

2. Release Layer Chemistry: Silicone Coated vs Non-Silicone Release Paper for PU Leather

The ability to cleanly and consistently peel the release paper from the cured synthetic leather is governed by the chemistry of the release layer. This thin coating applied to the textured paper base provides the non-stick properties. The debate between silicone and non-silicone release systems is central to this selection, as each offers distinct advantages and limitations that directly impact production and product quality.

Silicone-coated release papers are the industry standard for most polyurethane (PU) leather applications. Silicone offers an exceptional combination of high release efficiency, thermal stability, and chemical inertness. It creates a very low-surface-energy barrier that allows even delicate or highly textured films to detach without tearing or leaving residue. This ensures consistent surface quality across the entire production run. Silicone's stability across a wide temperature range (typically from -40°C to over 200°C) makes it suitable for various curing processes. Furthermore, modern silicone chemistries can be engineered to provide controlled release forces—from easy release to tighter release—allowing formulators to fine-tune the process based on the adhesive properties of their PU resin.

On the other hand, non-silicone release papers utilize alternative chemistries, such as fluoropolymers or specialized hydrocarbon-based coatings. These are sometimes employed in specific niches. Their primary reported advantage is the potential to leave a chemically different surface on the released PU film, which can be beneficial for subsequent adhesion steps. For example, in some multi-layer lamination processes or when a topcoat needs exceptional adhesion, a non-silicone release paper might be specified to avoid any potential silicone contamination or migration, which can create a weak boundary layer. However, non-silicone systems often have a narrower processing window, may require more precise control of curing conditions, and can generally withstand fewer reuse cycles compared to high-quality silicone systems. Their release force might also be less consistent over multiple uses.

Decision Factors Table: Silicone vs. Non-Silicone

The following table contrasts the key characteristics of silicone and non-silicone release coatings to guide the selection process. It is important to note that performance can vary within each category based on the specific formulation and paper base.

Release Efficiency and Consistency: Silicone coatings provide excellent, consistent release force with low surface energy, ensuring clean demolding cycle after cycle. Non-silicone coatings may offer good initial release, but consistency over multiple uses can be less predictable and may degrade faster.

Heat Resistance and Durability: Silicone exhibits superior thermal stability, maintaining performance across a broad curing temperature range and enabling more reuse cycles (often 50+ for high-grade papers). Non-silicone coatings generally have a lower maximum continuous use temperature and tolerate fewer production runs before release performance falters.

Chemical Compatibility: Silicone is highly inert and compatible with most PU, PVC, and other polymer systems, resisting solvent penetration. Some non-silicone chemistries may be susceptible to attack by certain plasticizers or solvents in the coating formulation, leading to paper degradation.

Surface Energy of Released Film: The released PU surface from a silicone paper has very low surface energy, which can be a disadvantage for downstream adhesion (e.g., printing, gluing) unless specifically treated. Non-silicone papers may leave a surface with higher intrinsic energy, potentially improving adhesion for subsequent processing steps without additional treatment.

Cost and Reusability: While the initial cost of premium silicone paper is high, its extended service life (high number of reuse cycles) often results in a lower cost-per-meter of produced leather. Non-silicone papers, potentially lower in initial cost, may need more frequent replacement, raising the long-term operational cost.

Comparison of Release Layer Types

Feature: Release Efficiency & Consistency; Silicone-Coated: Excellent, very consistent; Non-Silicone: Variable, can degrade faster with reuse.

Feature: Heat Resistance & Durability (Reuse Cycles); Silicone-Coated: High (50+ cycles common); Non-Silicone: Moderate to Low (fewer cycles).

Feature: Chemical Compatibility; Silicone-Coated: Broad, highly inert; Non-Silicone: Can be selective, may react.

Feature: Downstream Adhesion of Released Surface; Silicone-Coated: May require corona/plasma treatment; Non-Silicone: Potentially better for some adhesives.

Feature: Operational Cost Perspective; Silicone-Coated: Higher initial cost, lower cost-per-cycle; Non-Silicone: Possibly lower initial cost, higher cost-per-cycle.

3. Achieving Dimension: Requirements for Release Paper in Embossed Artificial Leather

Creating deeply embossed or three-dimensional patterns on artificial leather places the most demanding requirements on the release paper. Unlike shallow textures, a deep emboss must faithfully transfer sharp peaks, deep valleys, and sometimes severe undercuts without trapping air, causing webbing (where the resin bridges a valley), or tearing during demolding. The requirements for release paper in embossed artificial leather extend beyond simple texture replication to encompass paper flexibility, tensile strength, and the precision of the engraving process used to create the paper's texture. The paper must be pliable enough to conform perfectly to the substrate and coating head during application, yet strong enough to withstand the tension of being pulled through the production line and the mechanical stress of peeling away from a deeply structured, cured film. Any slight stretching or distortion in the paper will result in a blurred or distorted pattern on the leather.

The base weight and composition of the paper are critical here. Heavier weight papers (discussed in factor 5) generally provide better dimensional stability for deep embosses, resisting stretch. The backing must also have excellent internal bonding to prevent delamination when subjected to the forces of releasing a deeply locked-in pattern. Furthermore, the release coating must be uniformly applied to every micron of the complex texture profile. Incomplete coating in a deep valley can lead to a sticking point, causing a defect or even paper tearing. Manufacturers of embossing-grade papers often use specialized techniques like electrostatic coating to ensure the silicone release agent evenly covers the entire contoured surface. When selecting a paper for deep emboss work, it is imperative to test the exact combination of paper, resin, and process conditions. A trial run will reveal potential issues like release difficulty, pattern fill problems, or reduced paper life, allowing for adjustments before full-scale production begins.

Key Paper Properties for Deep Embossing

- Dimensional Stability: The paper must have minimal stretch under the machine direction tension to prevent pattern distortion. This is often achieved with a high-quality, densely packed kraft base and specific manufacturing processes that control paper grain direction.

- Precision Engraving: The original cylinder used to impart texture onto the paper must be crafted with extreme precision, often using advanced laser or diamond engraving techniques, to create sharp, clean, and consistent pattern depths.

- Uniform Release Coating Penetration: The release agent (e.g., silicone) must fully and uniformly wet the entire textured surface, including the deepest recesses and most acute angles, to ensure consistent release force across the entire pattern.

- Tear Strength and Flex Endurance: The paper substrate needs high tear resistance, especially in the cross-direction, to survive the peeling process without ripping, particularly when the cured resin has mechanically locked into the texture. Good flex endurance allows it to withstand repeated bending around rollers.

- Controlled Release Force Profile: For complex embosses, the release chemistry might be tailored to provide a slightly easier release to aid in demolding intricate patterns without damaging the freshly cured surface of the artificial leather.

4. Withstanding the Process: Heat Resistance and Durability of Transfer Paper for Leather Finishing

The production environment for artificial leather is physically and chemically demanding. Release papers are subjected to multiple stress factors during each cycle: high temperatures in curing ovens, tension from web handling systems, chemical exposure from solvents or plasticizers in the coating, and mechanical abrasion from guides and rollers. Therefore, evaluating the heat resistance and durability of transfer paper for leather finishing is a direct assessment of its operational lifespan and economic value. Heat resistance is arguably the most critical property. During production, the paper, with the wet coating, passes through ovens where temperatures can range from 120°C to over 200°C, depending on the resin chemistry and line speed. Prolonged exposure to these temperatures can cause several degradation pathways: the paper base can become brittle and lose tensile strength, the release coating can oxidize or break down, and the adhesive binding the release layer to the base can fail. A paper with poor heat resistance will yellow, become prone to cracking, and lose its release performance after only a few cycles.

Durability encompasses more than just heat tolerance. It includes the paper's ability to maintain its physical integrity—its tear strength, dimensional stability, and surface texture—over repeated use. A durable paper will show minimal "polishing" or flattening of its texture peaks even after dozens of production runs, ensuring the 50th roll of artificial leather has the same grain definition as the 1st. It will also resist "ghosting," where a faint impression from a previous coating remains on the paper and transfers to subsequent products. The choice of base paper (grade of cellulose, filler content, calendering process) and the quality of the release coating system are the main determinants of durability. Investing in a higher-grade, more durable paper often results in a lower cost per meter of produced leather, as the paper cost is amortized over many more cycles. It also reduces production interruptions for paper changes, increases consistency, and minimizes waste from defects caused by failing paper.

5. Operational Efficiency: How Release Paper Weight Affects Artificial Leather Production Speed

The physical specifications of the release paper itself, particularly its weight (typically measured in grams per square meter, gsm) and thickness, have a direct impact on production logistics and efficiency. The concept of how release paper weight affects artificial leather production speed involves a trade-off between performance and practicality. Heavier papers (e.g., 130 gsm and above) offer superior dimensional stability, which is crucial for high-fidelity pattern transfer, especially for deep grains and embosses. They are less likely to stretch under tension, which prevents pattern distortion. They also generally have better heat resistance and durability, as the thicker base provides a more robust substrate. However, the increased weight and thickness come with operational considerations. Heavier papers are more expensive per square meter. They result in larger, heavier rolls for the same length of paper, which can complicate material handling, storage, and loading onto the production machine. Crucially, the increased stiffness of a heavier paper can limit the maximum speed of the production line, as there may be limitations on how quickly it can be guided through complex roller paths without causing tracking issues or web breaks.

Lighter weight papers (e.g., 80-110 gsm) offer advantages in terms of flexibility and potential for higher line speeds. They are easier to handle, produce longer roll lengths for the same diameter (reducing changeover frequency), and can be more cost-effective for applications where extreme dimensional stability or deep emboss is not required, such as for smooth finishes or shallow textures. However, they are more prone to stretching, which can affect pattern registration in multi-step processes, and they may have a shorter service life due to lower inherent durability. The optimal weight is thus determined by the specific product requirements and the capabilities of the production machinery. A high-speed line producing fashion-grade leather with a fine grain might run optimally with a 100 gsm paper, while a line specializing in heavy-duty, deeply embossed furniture leather would necessitate a 140 gsm or heavier paper, even if it runs at a slightly slower speed to ensure quality and paper integrity.

Developing a Systematic Selection and Testing Protocol

Armed with knowledge of the five key factors, the final step is to implement a disciplined selection and testing protocol. This moves the process from theory to reliable practice. Begin by defining the non-negotiable requirements of your final artificial leather product: its target market, aesthetic (texture, gloss), physical properties, and price point. Use these to create a preliminary paper specification focusing on texture type, release chemistry, and weight. Engage with potential paper suppliers early, providing them with your resin specifications and process parameters (coating method, curing temperature profile, line tension). Request sample rolls of their recommended papers for comprehensive trials. Do not rely on small swatches alone; a production-scale trial is essential to evaluate performance under real conditions.

The trial should assess all critical parameters: ease of release and condition of the back of the paper after release, fidelity of texture transfer across the entire web width, consistency of gloss level, any signs of coating adhesion to the paper (poor release), and the behavior of the paper on the line (tracking, tension stability). Crucially, conduct multiple passes with the same paper sample to gauge its durability—how does the texture and release performance change on the 5th, 10th, or 20th cycle? Document everything meticulously. Based on the trial results, you can refine your specification. The goal is to identify the paper that delivers the required product quality with the fewest operational headaches and the best total cost-in-use, balancing initial paper cost with its lifespan and your production efficiency. Remember, the release paper is a production tool; its selection should be driven by data and a clear understanding of its role in creating value in your final artificial leather product.

Copyright © Anhui Honghuan New Material Technology Co., Ltd. Rights Reserved.

Custom Casting Release Paper Factory

English

English 中文简体

中文简体