Submit feedback

How Does PVC leather release paper Improve Product Quality and Efficiency?

Introduction

In modern manufacturing environments, selecting the right release liner material directly influences processing consistency, surface finish quality, and operational throughput. PVC leather release paper plays a key role in synthetic leather production, texture transfer, and high-temperature processing. This article explores how this specialized release paper enhances product quality and manufacturing efficiency, focusing on engineered performance, process control, and industrial applications.

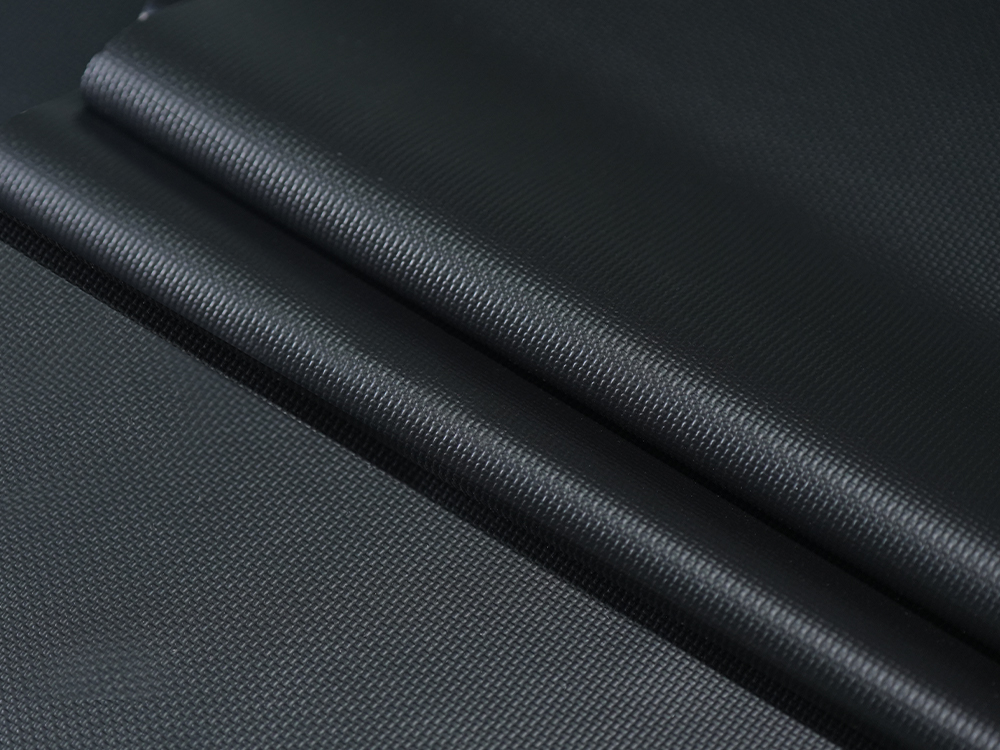

Overview of PVC leather release paper

PVC leather release paper is designed to facilitate clean demolding and precise texture transfer in synthetic leather, automotive upholstery, footwear, and coated surfaces. It typically consists of a polymer-coated paper base optimized for controlled adhesion and release performance. According to the latest report by Future Market Research, the market for synthetic and PU leather release papers is expanding steadily, reflecting broader adoption of advanced release liners in high-precision manufacturing.

Source: Future Market Report - Release Paper Market

Key Material Properties and Manufacturing Considerations

Key engineering attributes of PVC leather release paper include heat resistance, controlled release force, and surface energy tailored for PVC and synthetic leather adhesion. Optimized release papers such as PVC leather release paper high temperature performance withstand elevated temperatures of 180–220°C without deformation, while PVC release paper texture transfer efficiency ensures high-fidelity embossing and surface replication. The PVC coated release paper manufacturing process influences coating uniformity, thickness, and surface smoothness, all of which directly affect release consistency and product quality.

Material Comparison

| Property | PVC Leather Release Paper | Generic Silicone Release Paper |

| Temperature Resistance | High – suitable for 180–220°C processes | Medium – limited above 160°C |

| Texture Fidelity | Superior transfer accuracy | Good, lower repeatability |

| Release Consistency | Very consistent | Variable under high load |

Performance Benefits in Product Quality

The use of PVC leather release paper significantly enhances surface uniformity, reduces blemishes, and improves texture replication. For automotive upholstery and premium synthetic leather, high-quality release papers reduce batch rejections and ensure that downstream coatings adhere properly. The adoption of synthetic leather release paper for automotive upholstery has been correlated with a measurable decrease in material defects and improved finish consistency.

Operational Efficiency Improvements

From a production standpoint, optimized release liners reduce machine downtime, limit waste, and lower labor intervention. By leveraging eco-friendly PVC leather release liner solutions, manufacturers can achieve environmentally compliant production without sacrificing performance. Well-engineered release papers also accelerate demolding cycles, minimize cycle-time variance, and improve throughput efficiency.

Efficiency Benefits

- Shorter processing cycles due to predictable release behavior

- Reduction in waste from fewer defects

- Improved line stability with consistent release forces

Engineering Insights and Industry Context

Advanced research shows that innovations in coating technology have improved release characteristics by up to 25%, enhancing both quality and efficiency in high-temperature lamination and embossing processes. According to the Global Growth Insights 2024 report, manufacturers using high-performance release papers report consistent cycle times and reduced rework requirements.

Source: Global Growth Insights - Leather Release Paper Market

Quality Control Considerations

- Calibration of release force testing

- Monitoring silicone coating uniformity

- Tracking process temperature in high-heat lamination zones

Selecting the right release liner, such as PVC leather release paper designed for high-temperature applications with precise coating and release properties, directly impacts product quality and manufacturing efficiency. Understanding these advantages allows B2B buyers to make informed decisions and achieve consistent, high-quality outputs in synthetic leather and coated material production.

Frequently Asked Questions (FAQs)

1. What distinguishes PVC leather release paper high temperature performance from standard release liners?

This type offers enhanced thermal stability and consistent release behavior at elevated processing temperatures, critical for lamination and embossing operations in synthetic leather production.

2. How does synthetic leather release paper for automotive upholstery improve material finish?

It ensures reliable texture transfer and surface uniformity, reducing defects and improving finish consistency for automotive interiors and premium upholstery.

3. Why are eco-friendly PVC leather release liner solutions gaining importance?

Environmental compliance and sustainability initiatives are driving manufacturers to adopt eco-friendly release papers that minimize environmental impact while maintaining performance.

4. What role does the PVC coated release paper manufacturing process play in performance?

The process determines coating thickness, uniformity, and surface energy, all critical for consistent release force, texture fidelity, and reduced production defects.

5. Can PVC release paper texture transfer efficiency affect production throughput?

Yes, optimized texture transfer minimizes rework, accelerates cycle times, and improves overall line efficiency, directly impacting operational productivity.

Copyright © Anhui Honghuan New Material Technology Co., Ltd. Rights Reserved.

Custom Casting Release Paper Factory

English

English 中文简体

中文简体